Pokemon Go is coming to a warehouse near you!

/The Pokemon Go phenomenon, which has exceeded 500 million downloads worldwide, highlights the possibilities of augmented reality (AR) not just for gaming, but also for use in the supply chain. AR is a technology that superimposes a computer-generated sensory input such as sound, video, graphics, or GPS data into a user’s real view of the world.

A good starting point for augmented reality in the supply chain, is in warehouses, and DHL recently announced that they will expand testing of augmented reality in warehouses in Europe and the United States:

DHL Supply Chain is rolling out the next phase of its Vision Picking Program following a successful trial of the augmented reality technology in the Netherlands...and DHL is now expanding the program across different industry sectors on a global scale, forging another step forward for augmented reality solutions in logistics.

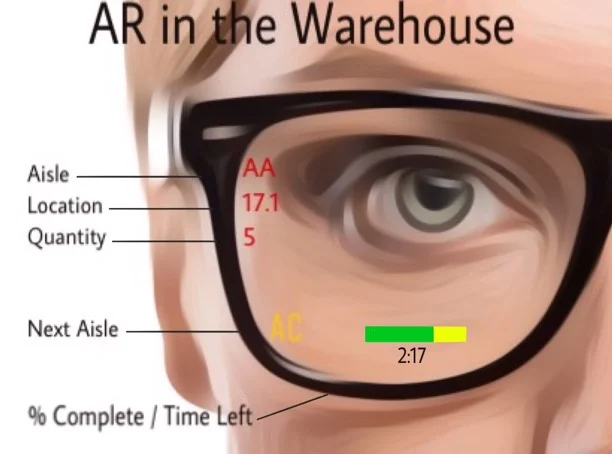

Augmented reality requires that warehouse workers are equipped with small glasses, like Google Glass, where a user will see a “digital pick-list” in their field of vision. The graphical representation displays the details for the task at hand. As an example, when arriving to a pick location, the glasses could overlay green over the correct location to indicate to the picker that they are in the right place:

Source: Vuzix, YouTube

And, when picking to trolleys the glasses could display an image of the product to pick, quantity to pick, and display the locations in the trolley to put the items. In the below example a DHL user is picking a total quantity of 3 to a trolley that could contain totes for multiple orders. The glasses display the tote positions that the items should be packed into:

Source: DHL, Ubimax, YouTube

Combined with voice instructions and the ability to scan from the glasses, augmented reality enables fully hands-free order picking which increases efficiency and reduces errors. While picking offers the most benefits, some additional use cases inside the warehouse include:

Route Optimization - The glasses can display the most optimal travel route inside the warehouse, like a GPS, to travel from one location to the next to reduce total travel time. In addition, real-time tracking of forklifts could allow for forklift routes to be changed dynamically to reduce congestion and improve safety.

Labor Management Digitization - As more millennials enter the workforce who have grown up with technology, making warehouse work more engaging and interactive will grow in importance. AR could display expected times to complete tasks based on labor standards which could be used to provide a real-time constant feedback loop for worker productivity. Warehouse workers could collect “tokens” when exceeding labor standards which could be used for performance plans, bonus programs, or employee contests.

Put/Pick Walls - Piece-picking operations may use put walls as a picking system that deconstructs and re-constructs orders to create an efficient order fulfillment process. AR could display which compartments to pick or put items from and overlay an indicator to provide visual confirmation that they are at the correct slot. AR has the potential to optimize this process while at the same time being far less costly and more flexible than traditional pick-to-light and voice-based system.

Value-Add Services (VAS) - Increasingly warehouses are providing value-add services to their customers ranging from product assembly, repair, labeling, and eCommerce VAS such as gift boxes, ribbons, and thank you cards. Currently, VAS may be done off system or confirmed via RF/Voice and typically require that workers are well-trained for each VAS process. AR could significantly enhance this process by guiding the worker through a series of steps with pictures of the work that needs to be completed, thus making the process more consistent and reducing the training requirement.

AR’s primary technical challenge is battery life and the size of the battery to make it practical for day to day use. This is a challenge that will be overcome, and will be helped by the fact that major players like Apple are getting behind AR; Apple CEO Tim Cook, recently stated that augmented reality will be bigger than virtual reality which indicates that Apple is investing significantly into AR. Apple, of course, will develop AR for consumers but their investments in AR will help push the technology forward and enable warehouse applications to piggyback off these advancements.

While it is difficult to gauge the pace of innovation and adoption of the technology, AR seems well-positioned to deliver compelling new user interfaces in the warehouse and it certainly is not a stretch to envisage a future where AR is as ubiquitous in the warehouse as RF hand-held scanners are today.

I cover forward-looking topics that are relevant for everyone interested in the future of logistics. You can read more articles here or sign-up for a free monthly newsletter here.

Below are some good links to vision picking demonstrations: