What is so special about October 23, 2005?

That’s when Walmart’s CEO at the time, Lee Scott, gave a speech entitled Twenty First Century Leadership that arguably kicked off the supply chain sustainability era.

“Environmental loss threatens our health and the health of the natural systems we depend on,” said Scott. The challenges include:

- Increasing greenhouse gases that are contributing to climatic change and weather- related disasters.

- Increasing air pollution, which is leading to more asthma and other respiratory diseases in our communities.

- Water pollution, which is increasing while safe, fresh water supplies are shrinking; water-borne diseases cause millions of deaths each year, mostly among children.

- Destruction of critical habitat, causing unprecedented threat to the diversity of life, the natural world and us. And that’s just to name a few.

“As one of the largest companies in the world, with an expanding global presence, environmental problems are OUR problems. The supply of natural products (fish, food, water) can only be sustained if the ecosystems that provide them are sustained and protected. There are not two worlds out there, a Walmart world and some other world.”

Two years later, in the fall of 2007, I chaired what I believe was the very first track on supply chain sustainability at the Council of Supply Chain Management Professionals (CSCMP) annual conference. Although there was a lot of buzz in the press about sustainability at the time, and the track featured some great speakers from companies that were leading the way (Herman Miller, Whirlpool, Campbell Soup, Stonyfield Farm), the sessions did not draw as many attendees as I had expected. My takeaway following the conference: there was a big gap between the hype in the press and where sustainability ranked on the priority list of most companies.

Supply Chains at the Center of Sustainability

Fast forward almost 13 years to today and “no self-respecting company is without a sustainability strategy,” says Dr. Yossi Sheffi (Director, MIT Center for Transportation & Logistics) in an October 2019 LinkedIn article. “And at the center of these strategies lies the supply chain.”

Sheffi adds, “For most companies, the majority of greenhouse gas emissions are generated in their supply chain. Poor labor conditions, the employment of child workers and human trafficking are among the social ills that lurk in supply chains. Daily newspaper headlines and various reports call out these growing and often hidden practices, inflicting substantial reputational damage to companies. Moreover, supply chain management is at the center of critical resource issues, such as how to reduce the ever-growing mountain of plastic waste that clogs our oceans.“

Last summer, we asked our Indago research community — comprised of supply chain and logistics practitioners from manufacturing, retail and distribution companies — if sustainability was a defined and measured objective within its supply chain organizations today. Almost 60% of the respondents said Yes.

We also asked our Indago members what actions their companies were taking to improve supply chain sustainability. The two most cited actions were “Increasing recycling of materials” and “Reducing waste from operations.”

Sustainability: A Byproduct of Supply Chain Efficiency

However, as the following respondent suggests, these actions are probably driven more by efficiency improvements than by sustainability: “I think sustainability is a good marketing tool, but not a main driver for most businesses. What is important, and will become more important, is efficiency. I think that as efficiency increases, sustainability will follow. For instance, the advent of personal computing reduced the need for paper files; sustainability is a by-product of efficiency.”

Sheffi makes another important observation in his article: “We’re not sure exactly what constitutes a sustainable supply chain. Moreover, it’s not clear what resources companies are devoting to sustainability in their supply chains and the extent to which they are under pressure to disclose and achieve their goals in this area.”

Our Indago members echo these points in some of their comments:

“While it does seem that supply chain sustainability is gaining traction from a PR point of view, from my experience sustainability is not really viewed as a critical need at the management level.”

“I believe that sustainability will continue to be a selling/differentiation point. I also believe, and have experienced it, that customers like to talk about sustainability, but will only push it if there is a cost savings … The expectation is that manufacturers will [absorb any added costs due to sustainability efforts] instead of partnering for a win-win.”

Therefore, it seems like the old adage “Green is good for business” remains true today — but mainly because the only “green” initiatives that get approved and worked on are those that reduce costs or have some other financial/efficiency benefit (or are required by law or regulation).

Transportation: At the Intersection of Sustainability and Efficiency

If sustainability is truly a byproduct of efficiency, then transportation is where the two intersect.

According to the Environmental Defense Fund, freight movement accounts for seven percent of all corporate greenhouse gas emissions, which come directly from trucks, trains, ships and planes that carry goods.

Not surprising, a lot of companies began their sustainability efforts years ago by focusing on their transportation operations first. This might explain why “Using optimization software to create more efficient transportation/fulfillment routes” ranked relatively low in our Indago survey: not because it’s not important for companies, but because they have already done it.

In my previous guest commentary on transportation optimization, I wrote that, “Regardless of how simple or complex your transportation operations are, you should always ask questions that challenge the status quo and seek opportunities to reduce costs, improve service, reduce risks and enhance the customer experience.” I left out one opportunity that a growing number of companies are adding to the mix: the opportunity to reduce their carbon footprint.

Any company using a transportation management system (TMS) to optimize and execute its transportation operations is, by default, helping to reduce its carbon footprint — whether it’s by consolidating multiple loads into a single truckload shipment, shifting to modes with lower carbon footprints (e.g., truckload shipments to rail or air shipments to ocean) or reducing miles traveled (and trucks used and gasoline consumed) to make local deliveries.

For companies that utilize both common carriers and their own private fleet, a TMS enables them to optimize across these available assets in a more integrated and intelligent manner. This typically translates into better utilization of private fleet capacity, fewer miles driven and fewer trucks on the road, which together lead to a reduction in carbon footprint.

On the transportation procurement front, a TMS can help companies incorporate sustainability into their bidding and selection process. For example, companies can include SmartWay participation as another factor used by the TMS to score and rank carriers across lanes. For some companies, SmartWay participation is a firm requirement.

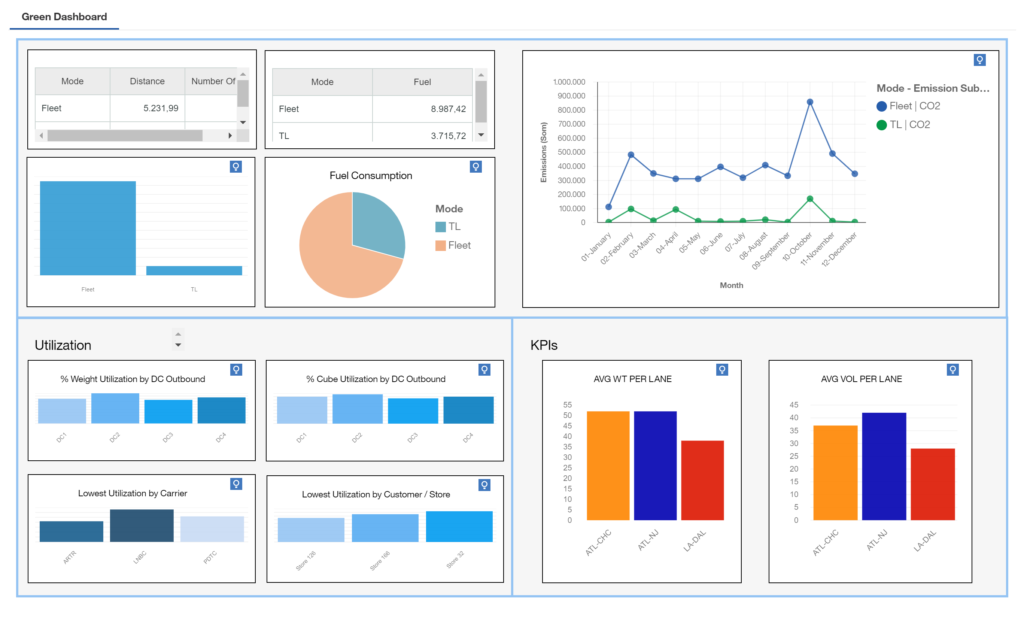

And when it comes to business intelligence and analytics, many TMS dashboards today provide visibility into sustainability metrics, enabling companies to understand the tradeoffs not only between cost and service across different modes and routes but also greenhouse gas emissions and carbon footprint. The screenshot below from Manhattan Associates’ TMS, for example, enables users to track sustainability KPIs/metrics to measure the progress of their green supply chain practices.

In short, you can almost say that the “S” in TMS stands for sustainability. Gregg Lanyard, Director of Product Management at Manhattan Associates, echoes this point:

“Supply chains are more dynamic and more fragile than ever before. When you think about continuous network design, and continuous optimization, a TMS inherently helps the environment as a whole. Identifying lanes for backhauls, determining the appropriate allocation for fleet versus common carrier resources, reducing deadhead miles across the network, increasing equipment utilization and reducing the number of shipments – all of these things support the effort. If you think about the analytics and reporting side, we can now better measure efficiency, fuel consumption and trailer utilization, as well as carbon footprint, thanks to a TMS. And when you measure things, things get done.”

More Opportunities to Improve

There is still a lot of opportunity in the transportation realm to improve both efficiency and sustainability. One of the biggest opportunities is to reduce the number of trucks required to ship products by developing smarter packaging and product designs.

In July 2015, for example, The Wall Street Journal published an article highlighting how IKEA is designing its packaging with shipping in mind, which for one product alone is translating into almost 7,500 trucks being removed from the road annually.

The WSJ also published an article about Sealed Air Corporation’s iBubble Wrap. Unlike the original Bubble Wrap, this new version is sold as flat plastic sheets that customers fill with air at their locations using a custom-made pump. Because the product ships as flat sheets instead of bulky rolls, one truckload of iBubble Wrap contains as much packing material as 47 truckloads of the old product!

There is also still a lot of opportunity to reduce empty miles and backhauls. For example, according to the National Private Truck Council, 26% of private fleet empty miles are available for backhauls, with 42% of those empty miles available “for sale” to others. However, matching this available capacity with available loads, and managing the execution and financial transactions, has always been a challenge.

The good news is that advancements in technology — most notably cloud computing, software-as-a-service, application programming interfaces and mobile computing — are making it easier for shippers, carriers and brokers of all sizes, as well as private fleets and others in the transportation ecosystem, to more easily integrate and transact with one another.

Supply Chain Sustainability Begins with Design

I began my career as a product development engineer, and one of the truths you quickly learn is that any changes you make to a product at the design stage will be orders of magnitude easier and less costly than making them once a product is in full production.

Simply put, the decisions you make at the design stage often have long-lasting effects, so it is best to think through all of the options and trade-offs up front (see Boeing 737 MAX problem).

The reality is that most products and supply chains today were not designed with sustainability in mind. If you do not design a product, for example, in a way that makes it easy and cost effective for someone to take it apart and reuse/recycle its materials, then it will likely end up in a landfill. Similarly, if you design your supply chain network and make significant capital investments in factories and distribution centers without factoring in carbon footprint or other sustainability considerations, then you’re basically stuck with the network you have for years unless you are willing to take a financial hit.

We have certainly made progress in supply chain sustainability since that October day in 2005. But there is still a gap between what companies say about sustainability and what they actually do. The best way to close that gap moving forward is to incorporate sustainability in supply chain design.

Editor’s Note: This post was originally published by Manhattan Associates as a guest commentary on the resources section of its website.