This post has already been read 12187 times!

In part 1 of Guardian of the Supply Chain, we looked at how Imperial Logistics is using a blockchain-enabled control tower to secure their global pharmaceutical network from fraudulent products. In part 2, we’ll look at how it works in a little more detail.

To recap, Imperial Logistics is using a three-pronged strategy to secure their supply chain that distributes 400 million patient packs a year across Africa, with supply lines extending to India and China.

“A key goal for us is around patient safety; being able to manage the complexity and quantity that’s going to proliferate the supply chain, as you move to patient-pack serialization. The only way to do that, in our humble opinion, is through a digital platform.” – Clinton de Souza, Imperial Logistics

The strategy includes:

- Blockchain Enabled Control Tower – for operational, end-to-end visibility with a single version of the truth for the whole supply network

- Serialization and Authentication – to identify, verify and track product through the supply chain and help manage recalls

- Above Market Visibility – using machine learning, artificial intelligence, ability to build algorithms that sift data from 4 billion patient pack scans and identify problems

Central to Imperial Logistics approach and solution is a control tower. A control tower is a potent tool in the management of supply chains as it aggregates scattered information from across the network into a coherent, insightful and actionable form. It’s important to note that the control tower itself is industry-agnostic. So while Imperial Logistics employ it in pharmaceutical supply chain, it’s just as valuable in any other industry that has a complex and distributed supply chain.

For example, Dana in the automotive industry has seen dramatic results by implementing a similar solution, giving them visibility to the extended supply chain through all tiers of supply. In the automotive and heavy manufacturing supply chains, a supply disruption can be expensive, so that 20/20 vision upstream is critical.

“[Dana] needs to be able to see multiple tiers down because if the Indian supplier didn’t ship the product in time, they could short the 3PL warehouse, which in turn would short the factories, which in turn would short their OEM customers… So, by seeing that second tier, you can make sure that some supplier in the middle of nowhere isn’t going to create a ripple effect to cause you to shut down a factory or miss a delivery target window on a customer.” (Tech Target: Auto Parts Maker Improves Supply Chain Efficiency)

A panoramic view of the supply chain through every tier enables you to see potential and emerging issues early, foresee their impact, and resolve them quicker and cheaper. - Nigel Duckworth Click To TweetA panoramic view of the supply chain through every tier enables you to see these potential and emerging issues early, and foresee their impact downstream on you and your customers. Then they enable you to resolve them faster and more cheaply because you know where everything is so you can adjust in the way that makes the most sense.

Four Keys to Control Tower Effectiveness

The benefits with a network-based control tower such as One Network’s that Dana and Imperial Logistics are using, extend way beyond typical visibility solutions to provide:

- Visibility – End-to-end, multi-tier visibility for the full, real time picture of what’s happening now and a preview of what’s ahead (not a rear view when it’s too late)

- Early Warning Alerts – to threatened milestones and pending problems, and this in the context of service level agreements and actual lead times (not static estimates)

- Decision support – intelligent agents recommend resolutions to users and enable them to execute those resolutions (or their own) through the control tower

- Autonomy – intelligent agents running in the execution layer can identify and often fix issues themselves, managing the supply network autonomously

One Network’s Control Tower absorbs data from virtually any external facility, system, or device, including IoT sensors and scanners, like the handheld spectrometer that Imperial Logistics is using to verify drug quality and authenticity. ERP and legacy systems are also vital contributors that enable supply chain planners to monitor and manage the supply chain.

The incorporation of Blockchain provides an indisputable, trusted and transparent record of assets and transactions for all parties in the supply network. Blockchain can be used to support applications such as chain of custody, serialization and authentication, and traceability. (One Network supports both Ethereum and Hyperledger Fabric.)

The Necessity of a Multiparty Network

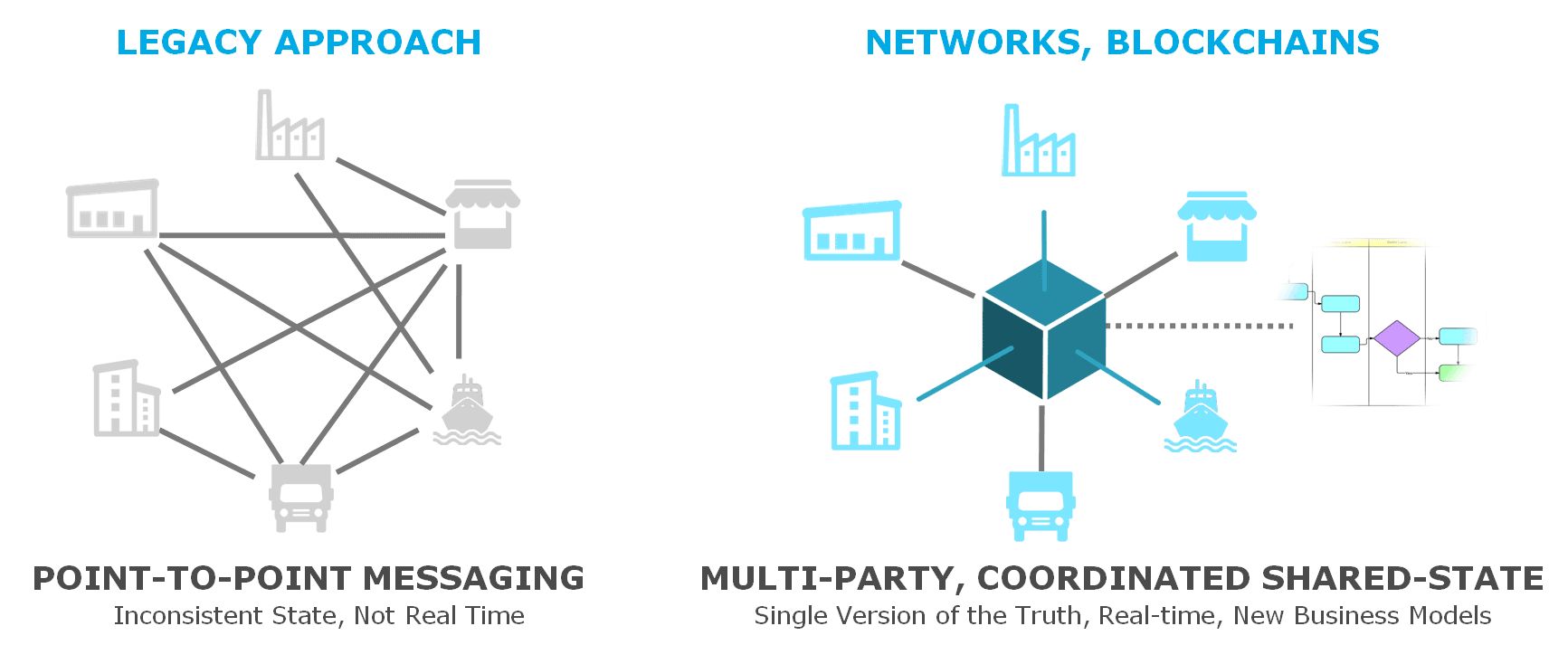

In order to achieve this level sophistication and power, a control tower needs to reside on a true multiparty network. Traditional enterprise systems with point-to-point connections to trading partners are neither fast enough nor scalable to meet the needs of a complex global supply chain. They cause and exacerbate many of the issues in the supply chain by adding information delays and stale data. The lack of complete and real time data contributes to confusion, poor planning and sub-optimization.

A real time multiparty network enables each partner to connect once and be connected to all other supply chain partners, from suppliers, manufacturers, distributors, retailers and carriers. There is a real time, single version of the truth for partners. Partners are better aligned around metrics and goals. They can collaborate in real time. Optimization algorithms can consider all factors and all constraints to deliver far more accurate and practical recommendations.

Related: How to Get Optimal Value from a Control Tower

The result is a network of trading partners that work together to serve the end-customer. With full visibility to real time demand, supply and logistics, they can coordinate better to achieve higher service levels much more efficiently. Companies on the network also see lower inventory levels, improved operational efficiencies, and can respond more rapidly and effectively to changing market conditions.

“One Network delivers product serialization, authentication and traceability on a Blockchain-enabled network platform. It delivers agility, velocity and transparency across the network, as well as significant supply chain performance improvements, in terms of product availability, service levels, inventories and costs.”

These are just some of the highlights of control towers and the solution Imperial Logistics are using. I recommend watching the webinar Imperial Logistics Blockchain-Enabled Control Tower which covers the Dual Platform Strategy, the Agile and Self-Funding Implementation method and much more.

- How Chain of Custody Strengthens the Supply Chain - October 11, 2022

- Inside Next Generation Supply Chains - November 8, 2021

- Pandemics, Trade Wars and Warehousing 2: Optimizing for Uncertainty with Real Time Business Networks - August 19, 2020