Table of Contents

** Minutes

What is inventory replenishment?

Why is inventory replenishment important for ecommerce retailers?

3 inventory replenishment methods

Inventory replenishment best practices

Inventory replenishment is easy with ShipBob

After hours of searching online, you finally find the product you’ve been looking for — only to find out it’s out of stock. It’s a huge let down, and it’s a lost sale for the merchant.

Even if the product is temporarily out of stock, it will take much longer to fulfill and ship. 34% of businesses ship orders late due to items being out of stock at the time of purchase.

Inventory management is a crucial part of the ecommerce supply chain that impacts customer loyalty and the overall brand experience.

Managing inventory involves maintaining optimal stock levels, so all products featured on your store are in stock and ready to ship.

In this article, you will learn about the inventory replenishment process, why it is important, and how a fulfillment provider like ShipBob can help.

What is inventory replenishment?

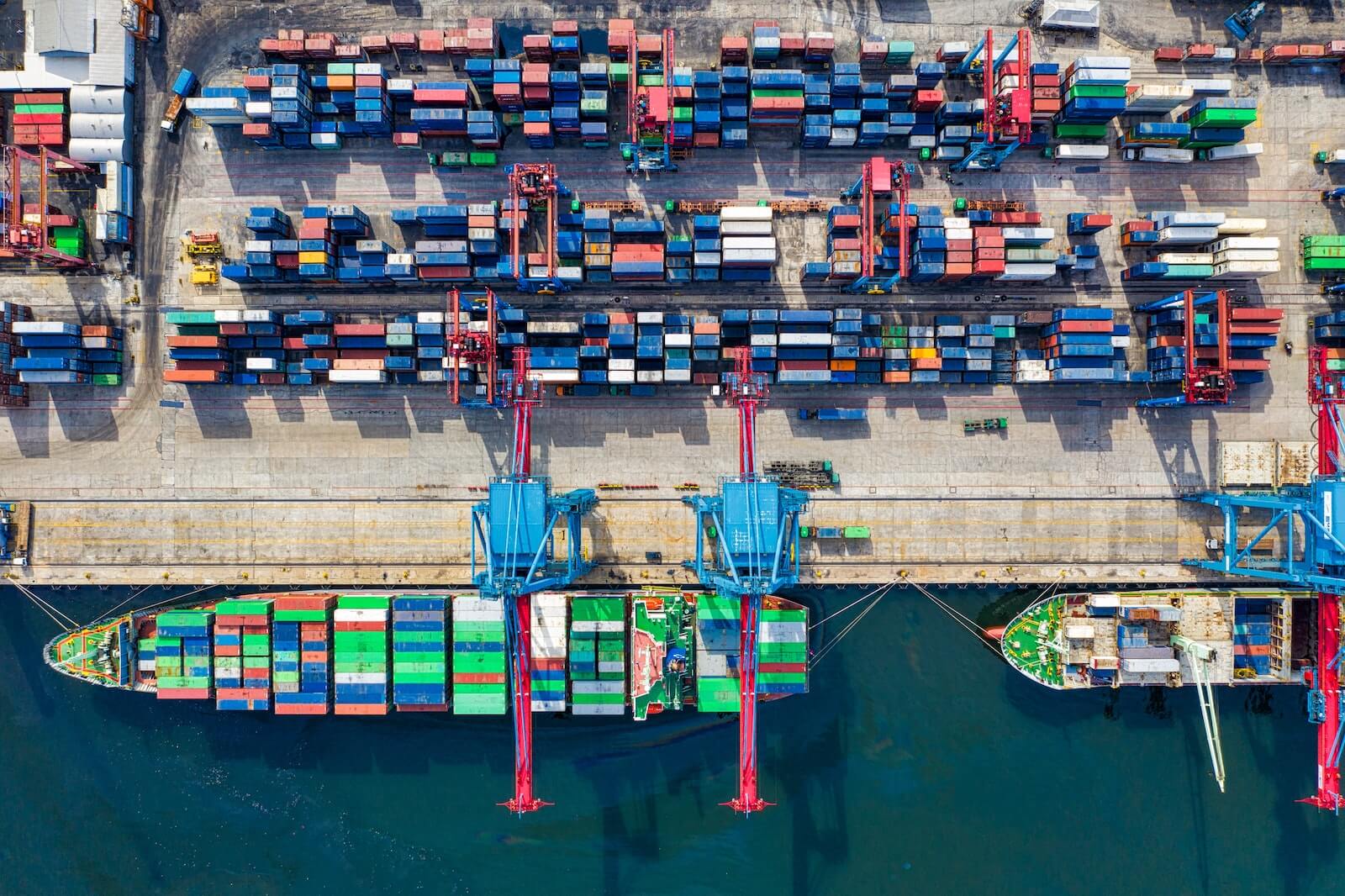

Inventory replenishment, also known as stock replenishment, refers to the process of moving products from inventory storage to picking shelves, or receiving ecommerce inventory from a supplier to stock it in a warehouse or fulfillment center.

When the replenishment process is managed correctly, there is enough inventory ready to be picked and packed as soon as each order comes in. Inventory replenishment is one of the most essential logistics operations tasks as it can highly impact customer satisfaction.

Why is inventory replenishment important for ecommerce retailers?

Efficiently replenishing inventory is a critical process that directly impacts an online brand’s ability to meet customer demand, fulfill orders, and turn a profit. Here are three reasons why inventory replenishment is important for ecommerce retailers.

1. Avoid stockouts

If a merchant fails to replenish inventory at the correct time, they risk having a stockout, which consists of items being out of stock at the time of purchase.

Backorders can also occur, which means an order has a pre-determined date on when the item will be available to ship. Both stockouts and backorders can cause major frustration for your customers.

The best way to avoid common stockout issues is to always have safety stock, a certain amount of back-up or emergency inventory on hand. This is also a good idea in case there is an unexpected supply chain issue (which many merchants experienced when the COVID-19 pandemic hit).

2. Prevent overstocking

A smart inventory replenishment process can also help prevent overstocking on inventory that might become unsellable if it sits too long, including food and beverages or cosmetics products that have an expiration date. Similar to not having enough inventory, overstocking can also impact your bottom line.

Replenishing stock too early or without regard to changes in customer demand or seasonality can cause dead stock, which increases carrying costs by having unsellable inventory sit on shelves for too long.

To avoid overstocking and high warehousing logistics costs, the economic order quantity (EOQ) formula is a simply way to find the optimal amount of inventory to have on hand to meet order demand.

By calculating EOQ, you gain a better understanding of how much inventory, including safety stock, you should have on hand while keeping ecommerce warehousing costs as low as possible.

3. Reduce shipping costs

Let’s say a customer ordered several items from you at the same time. If one item is out of stock at the closest warehouse location to the customer but is available at a different location, you would need to send asplit shipment (sending different items from one order in separate packages, often from a different location or at a different time) to fulfill the customer’s entire order.

Sending items from one order in multiple shipments increases shipping costs, creates more packaging waste, and can cause customers to be confused. By forecasting demand, you can decide how much inventory at the SKU level to store at each warehouse location based on historical data.

Note: Spitting your inventory across fulfillment centers is a retail supply chain best practice that consists of keeping inventory closest to your customers.

It can reduce shipping costs and last-mile delivery. However, each fulfillment center location should always be stocked with the right amount of inventory for this fulfillment strategy to work the way it should.

3 inventory replenishment methods

Different ecommerce retailers employ different replenishment methods, depending on their business model, monthly order volume, and products. If you are hitting roadblocks with your current replenishment strategy, here are three effective inventory replenishment methods to adopt.

1. Reorder point method

Inventory reorder points helps to ensure you always have enough stock on hand to satisfy customer demand. Reorder points also provide more financial flexibility by keeping a minimum amount of inventory in stock at all times.

The reorder point formula (demand during lead time + safety stock) helps you calculate the right stock levels to meet customer demand, so you know the reorder quantity you need and when based on historical order data.

Note: Keep in mind that a single reorder point will not work for every SKU — all products have different reorder points and should be calculated accordingly.

2. Top-off method

When your inventory includes a lot of fast-moving SKUs, the top-off method tends to be the most suitable inventory replenishment strategy.

Using this strategy, inventory levels for a particular product are “topped off” in their respective storage locations during slower periods or down time, so that you can maintain a highinventory turnover ratewithout encountering stockouts for pickers.

3. Periodic inventory replenishment method

Using the periodic inventory replenishment method, inventory is restocked at set intervals. Inventory levels are only assessed at periodically specific times or dates, no matter how low stock levels may drop before that point. This method is mostly used in warehouses with larger storage capacity.

Inventory replenishment best practices

An effective inventory replenishment strategy takes planning and effort to develop. While planning, you should always do your research and incorporate the following three best practices into the inventory replenishment process.

1. Implement the right technology

Having the right ecommerce tech stack in place can help you optimize your supply chain.

For instance, implementing inventory management software is an easy way to provide more visibility into inventory levels in various locations in real-time, which can help you make better inventory decisions.

By using inventory automation tools for inventory optimization, you can easily stay on top of inventory control, track inventory trends, and avoid common stock issues.

“Another ShipBob integration I love is Inventory Planner. It saves me hours every week in Excel spreadsheets, and I can raise a PO in minutes when it used to take me hours.

For every order I placed for years, I was ordering too much or not enough. Between inventory forecasting tools and the ability to auto-create WROs, we don’t have stockouts much anymore. I sleep better at night.”

Wes Brown, Head of Operations at Black Claw LLC

2. Use inventory replenishment data

Having access to real-time inventory data gives you insights into which items are slow moving versus fast moving, so you can make better decisions on when it’s time to reorder inventory.

Armed with this data, you will be able to improve demand forecasting, calculate safety stock quantities, identify inventory turnover rate for your products, and other considerations that can impact your business financially.

“ShipBob’s analytics tool is really cool. It helps us a lot with planning inventory reorders, seeing when SKUs are going to run out, and we can even set up email notifications so that we’re alerted when a SKU has less than a certain quantity left. There is a lot of value in their technology.”

Oded Harth, CEO & Co-Founder of MDacne

3. Create better inventory management strategies

Inventory replenishment is just one function of the entire inventory management process. Without a proper inventory management process, it will be difficult to make decisions on when it’s time to reorder inventory.

Regular inventory audits, standard warehouse receiving procedures, and warehousing best practices can help you track inventory more efficiently.

Holding costs — including warehouse staffing, storage, shrinkage, and depreciation costs — should be closely monitored and calculated to ensure there is no major cuts into profit margins.

“Now we’re at two ShipBob fulfillment centers, and being able to have the analytics and see how everything is working together has been extremely helpful for me on the operations end.

It definitely helps me with inventory management and seeing what’s going on. It truly helped us on a day-to-day basis. Even though we’ve grown, I haven’t spent more time on the business from an operations standpoint.”

Dana Varrone, Director of Operations at Organic Olivia

Inventory replenishment is easy with ShipBob

ShipBob is a tech-enabled 3PL that offers best-in-class fulfillment solutions, a global fulfillmentnetwork, and proprietary technology.

ShipBob offers ecommerce fulfillment services, from warehousing to order fulfillment, kitting to automated shipping and returns processing, so our customers have what they need to build an end-to-end ecommerce solution.

ShipBob’s technology includes built-in inventory management software, as well as an advanced data and analytics reporting tool.

“We have a Shopify store but do not use Shopify to track inventory. In terms of tracking inventory, we use ShipBob for everything — to be able to track each bottle of perfume, what we have left, and what we’ve shipped, while getting a lot more information on each order.”

Ines Guien, Vice President of Operations at Dossier

All from one dashboard, you can track inventory levels in real time, set automatic reorder points, and access important inventory insights, such as inventory forecasting tools, to help you make better business decisions.

ShipBob provides everything you need to manage inventory and fulfill orders accurately at your fingertips, so you can optimize your supply chain and save on time and money as your business grows.

Improve inventory management with ShipBob’s WMS

For brands looking to store inventory and fulfill orders within their own warehouses, ShipBob’s warehouse management system (WMS) can provide better visibility and organization.

Ecommerce merchants can now leverage ShipBob’s WMS (the same one that powers ShipBob’s global fulfillment network) to streamline in-house inventory management and fulfillment. With real-time, location-specific inventory visibility, intelligent cycle counts, and built-in checks and balances, your team can improve inventory accuracy without sacrificing operational efficiency.

For brands looking to scale internationally, ShipBob even offers a hybrid solution where merchants can employ ShipBob’s WMS technology in their own warehouses while simultaneously leveraging ShipBob’s fulfillment services in any of ShipBob’s fulfillment centers across the US, Canada, Europe, and Australia to improve cross-border shipping, reduce costs, and speed up deliveries.

Conclusion

Optimizing inventory levels might seem challenging, but with a third-party logistics (3PL) partner like ShipBob, you can outsource fulfillment and let the experts take care of retail warehousing, inventory management, and retail fulfillment for you. This way, you can spend less time on fulfillment logistics and more time on building your online business.

“So many 3PLs have either bad or no front-facing software, making it impossible to keep track of what’s leaving or entering the warehouse.

On the supply chain side, I just throw in what we placed at the factory into a WRO in the ShipBob dashboard, and I can see how many units we have on-hand, what’s incoming, what’s at docks, and so on. I can see all of those numbers in a few seconds, and it makes life so much easier.”

Harley Abrams, Operations Manager of SuperSpeed Golf, LLC

To learn more about how ShipBob works, click the button below.

Inventory replenishment FAQs

Here are answers to ecommerce business owners’ most frequently asked questions about inventory replenishment.

What are replenishment orders?

Replenishment orders are orders that a merchant files with a manufacturer to receive more raw products to go into reserve storage, so that the merchant can continue moving inventory onto picking shelves, into fulfillment, and through the supply chain.

Why is inventory replenishment important?

Beyond refilling a business’s picking shelves with fresh stock that can be sold, inventory replenishment (and a calculated strategy for how to do it) is a critical skill because it allows businesses to avoid the costly mistakes of overstocking, stockouts, and split shipments.

How do you increase inventory replenishment?

To increase inventory replenishment, you first need to have a high inventory turnover rate, meaning that you sell inventory at a quick pace and thus must replenish often, and a low days sales in inventory, meaning that you sell through your entire inventory quickly. This is not necessarily something that merchants have control over, as they are at the mercy of customer demand and market trends.

However, demand forecasting and data-driven inventory management can help an ecommerce business determine when and how often they should replenish their inventory.