Carrier Capacity Management Levels the Playing Field in a Carriers’ Market

Logistics Viewpoints

DECEMBER 7, 2021

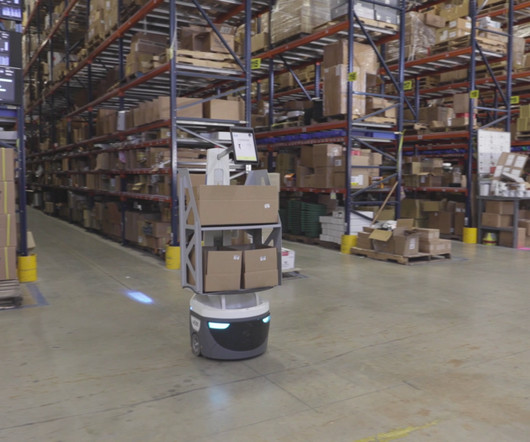

Workforce shortages and other challenges abound throughout all transportation sectors, and while this may revitalize investments in localized manufacturing, expanded warehousing to hold more inventory, and other efforts, these changes do not solve today’s issues. Carrier capacity tops the list of parcel shippers’ challenges.

Let's personalize your content