The ‘Biggest Ever’ Vaccine Distribution Campaign

As manufacturers move closer to finalizing and distributing a vaccine for Covid-19, pharmaceutical companies are preparing for a massive surge in their distribution networks. Pfizer, has already invested $2 billion in developing and distributing the vaccine in what Pfizer’s supply chain VP, Tanya Alcorn, referred to as their “biggest ever vaccination campaign”.

To speed a vaccine to market, Pfizer has already built up its raw materials supply chain and manufacturing capacity prior to FDA approval of the drug. On the distribution side, Pfizer recently turned a 60,000 square foot plot of land into a vaccine distribution hub with 350 large freezers. Their goal is to distribute 100 million doses by the end of the year and an additional 1.3 billion doses in 2021.

On top of distributing millions of doses, Pfizer’s Covid-19 vaccine has to be maintained at a temperature below -18°C. To overcome this challenge, Pfizer created reusable ‘Cool Boxes’. These temperature controlled containers can keep up to 5,000 doses below -18°C for 10 days. In addition, these containers are tracked by GPS to help address concerns about counterfeits and smuggling.

Elongating the Holiday Season to Increase Sales and Ease Distribution

Although Halloween does not see the same sales spikes as other holidays, retailers can learn a few lessons from the results of Halloween candy sales. With limits on parties, trick-or-treating and other events, overall Halloween sales took a hit. Costume sales bore the worst of it, but candy makers stayed ahead of sales forecasts by promoting and offering discounts several months in advance.

Following suit and preparing for the largest sales holiday of the year, Walmart, Target and Best Buy offered “Black Friday” discounts during Amazon’s Prime Day. Offering earlier holiday discounts eases the complex order surges distribution channels face and decreases crowds at physical stores. The National Retail Federation reported that 53% of shoppers plan to buy gifts early due to concerns of delivery and product availability. With a possible resurgence of new Covid cases and an election happening in November, retailers are entering a period of extreme uncertainty. Building up inventory now and elongating the holiday season will help ease fulfillment.

Amazon Business See A 67% Increase In Sales By Focusing on Logistics

Since its launch in 2015, Amazon Business has been Amazon’s fastest growing unit. Amazon Business is forecasted to top $31 billion in revenue by 2023. According to Mark Mahaney, managing director at RBC Capital Markets, “They are building out the lowest-cost distribution business out there.”

Amazon’s success in the B2B space is attributed to their focus on logistics. Prior to the launch of their B2B unit they were focusing on decreasing their reliance on third party transportation companies and building up their own end-to-end fulfillment network.

Amazon now operates close to 1600 logistics facilities (receiving centers, fulfillment centers, sortation stations, air hubs, warehouses and last-mile delivery stations) around the world. Amazon’s focus on their logistics network has helped them deliver products faster, more efficiently and at a cheaper, more fixed price.

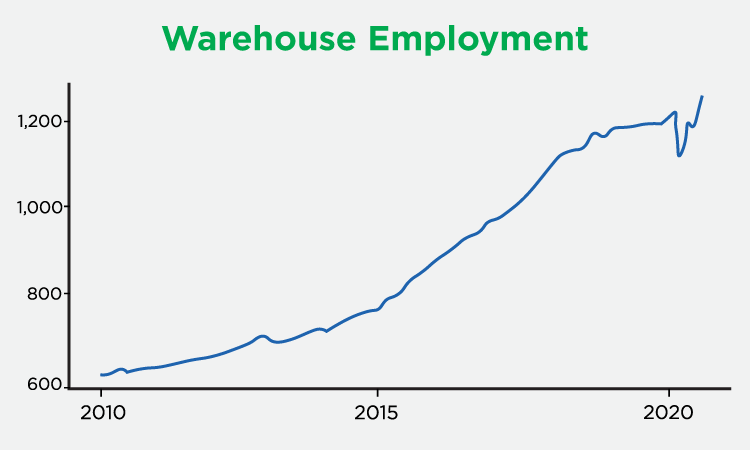

Warehouse Employment Sets A New Record

After a slight dip in from the initial pandemic shut downs, warehouse employment has recovered and now continues to rise. A recent report from the Bureau of Labor Statistics stated that there are currently 1.25 million people working in warehouses. In addition, delivery companies added 10,300 jobs last month and trucking companies added 4,600.

The pandemic sped up the growth of ecommerce by a few years and most consumer surveys show the trend is here to stay.

How Robotic Micro-Fulfillment, AI and Manual Processes Will Transform Fulfillment

To improve local fulfillment, many retailers are planning for a hybrid future with localized fulfillment centers, dark stores, and two-channel stores. Within this hybrid real estate, micro-fulfillment technology will co-exist with AI optimized manual processes to provide retailers with flexible, efficient operations across all facilities. To get there, most retailers are following a “crawl, walk, run approach,” focusing first on optimizing manual picking processes and slowly adding micro-fulfillment technology rather than betting the business on fully automated solutions out of the gate.

Our recently published article, How Robotic Micro-Fulfillment, AI and Manual Processes Will Transform Fulfillment, provides an overview of the key challenges for picking in stores, process improvements, micro-fulfillment technology and marrying up micro-fulfillment with AI and manual processes to deliver products faster without impacting in-store shoppers.