When Do You Need a PLM System?

All our customers, no matter industry, maturity, or complexity, have had to answer the same question: when to implement a real product lifecycle management (PLM) system?

All our customers, no matter industry, maturity, or complexity, have had to answer the same question: when to implement a real product lifecycle management (PLM) system?

Every company has more on the “to do” list than resources. You have many business needs—ranging in scope and impact—and a finite pool of people and budget that will not cover all the business needs. What does this mean? You’ll need to prioritize your projects. And, if you are a product company, one of these projects will eventually be a PLM solution because one of your business requirements is to bring new features and products to market in a predictable, efficient way. PLM helps you do this.

How do you prioritize this project against all the other projects, particularly when you are a younger company with too much to do? How long can you get by with Excel, DropBox, email, and Zoom calls? Let me share some research from our customers that will help.

Not Covered Here: Software Requirements, Business Value, TCO, ROI

Before we start, a disclaimer. In this blog, we aren’t going to talk about the specific business needs or processes that PLM supports, the requirements you need to define for a solution, the business value a good solution should provide, or total cost of ownership (TCO) evaluations and return on investment (ROI) calculations. These are all important considerations you need to address ONCE you decide it is time for a PLM. We are going to talk about what should determine the best time for you to put a scalable, purpose-built platform in place—instead of the spreadsheets or square-peg tool you might be using today.

Timing Drivers

We work with a lot of product companies—startup to large; across many industries; and with a range of products in volume, price, and complexity. We track what drives our customers to buy a solution at the point in time they do—their timing drivers.

A timing driver is the reason you will prioritize this project above other projects right now and is the combination of company stage, upcoming product events, company culture, and recent experiences.

What are timing drivers? For our customers, we’ve identified five primary timing drivers:

- Growth

- Gross inefficiencies

- Proactive pain avoidance

- Upcoming new product development and introduction (NPDI) events

- Compliance

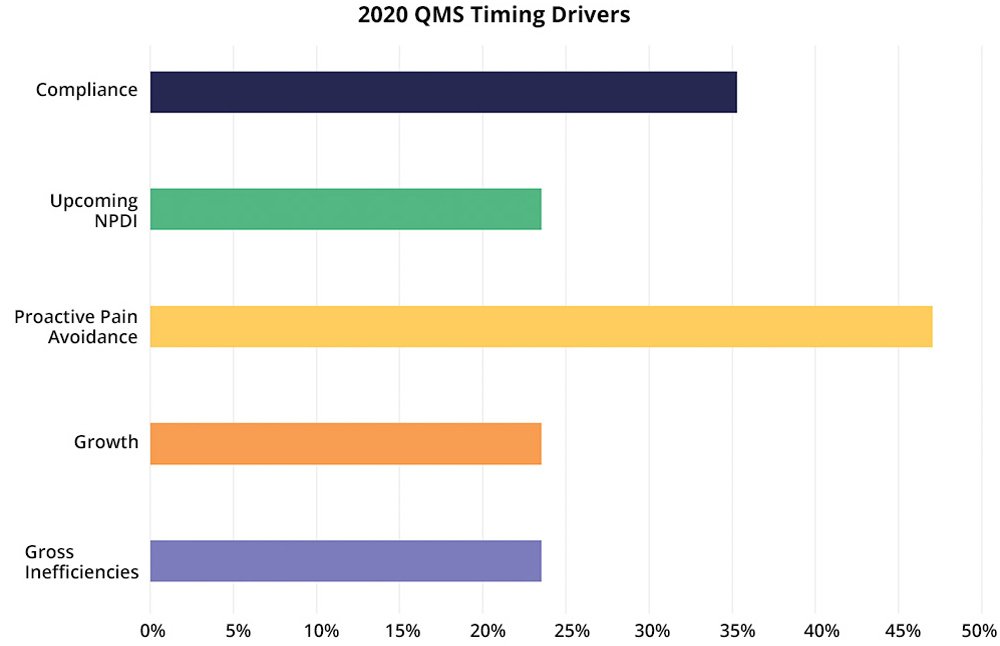

While these drivers as categories have held steady over the years for our customers, how much each driver shows up has varied across years, given the overall economic, competitive, and political climates. Here we’ll look at our 2020 Arena freshman class of customers to see the importance of each driver in this season.

- Proactive Pain Avoidance

Interestingly, this driver is the most-often cited in 2020 (so far). Proactive companies are typically companies with experienced team members who have “been there, done that” and know that they need to put certain systems and processes in place before costly mistakes occur due to errors or challenges when they begin to scale. While 2020 seems an odd year to be proactive, if your company is fortunate to be on solid financial and market footing right now, it is a good time to prepare for your next stage. Additionally, the year 2020 has shown businesses areas of weakness or risk that can be improved to guard against future disruptions.- Growth

Times of growth create good problems for companies to solve as existing tools, processes, and methods needed to be reviewed for update and replacement. While 2020 has seen falling revenues in some industries, in many product markets the demand has exploded while for others it has remained steady. Think of health and wellness products, remote work tools, and almost anything that makes your abode a home. In companies with multiple timing drivers, growth is the top driver.- Gross Inefficiencies

If you are doing PLM activities with a mix of generic tools, you’ll have inefficiencies. Inefficiencies usually function as a cost of your current way of work, but the work still gets done even if you use a specialized (high-cost) team that could be doing more valuable work. However, for some companies, inefficiencies are too painful due to extremely limited resources (people). The result is that you are not able to get product work done anywhere close to on time. In this situation, we have gross inefficiencies becoming a driver of when to make the switch, not if.- Upcoming NPDI Events

For product companies, NPDI happens. While NPDI is a routine part of progress (growth), you might have a particularly high-profile product launch in the future or multiple product projects with complexities (expanded supply chain, new markets, new revenue goals, competitive play) that require you to put a PLM solution in place to reduce risk.- Compliance

For some industries, compliance is always a requirement. For medical device companies, that’s always top-of-mind. For less regulated companies, like those with ISO 900X certifications, compliance is a timing driver though it tends to be about upcoming events, such as external audits, certification objectives, and regulatory filings.Importance of Timing Drivers

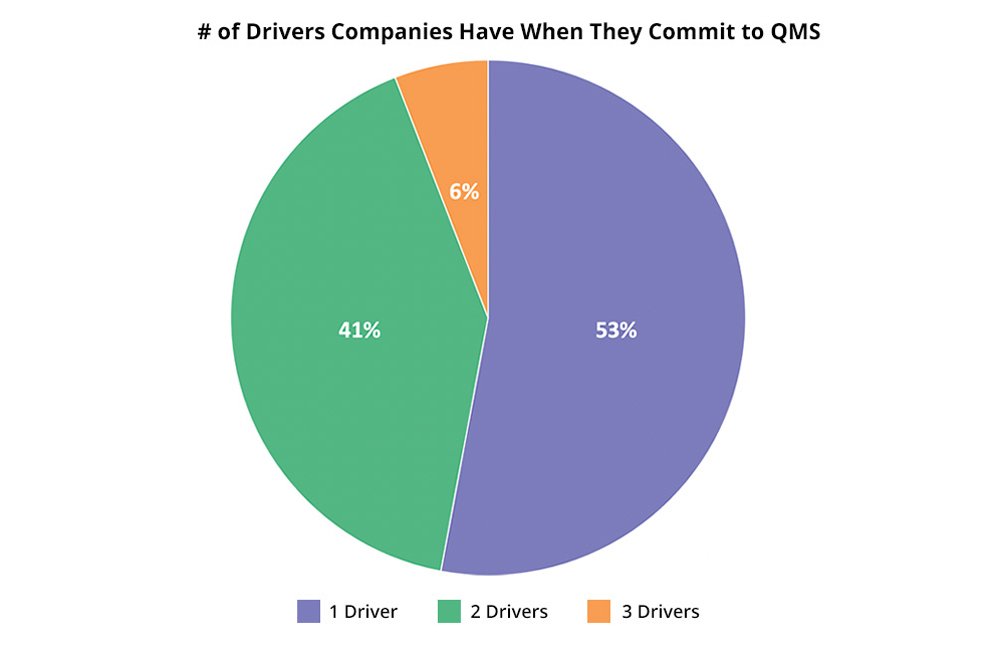

In working with our customers for decades, we’ve learned that the more timing drivers they have, the more likely they will be able to get the budget, resources, and political will to implement a PLM. While 50% of our 2020 new customers had only one primary timing driver, 50% had two or more.

More importantly in customers with more than one primary timing driver, growth and proactive pain avoidance are the most frequent and are forward-looking, positive drivers.

Determine Your PLM Timing Drivers

You will want to have conversations with your team about what is going on in your company: your product development and manufacturing projects, company goals, other projects competing for resources, and the company culture. Gaining a big picture of what is going on over the next time period will help with your PLM solution timing.

Remember: A timing driver is the reason you will prioritize this project above other projects right now and is the combination of company stage, upcoming product events, company culture, and recent experiences.

Once you have the big picture, you’ll identify your PLM timing drivers.

Here is a quick scoring card along with common (and real) examples from Arena customers for each driver. Check off your timing drivers.

✔

Timing Driver

Examples

Proactive Pain Avoidance

- We are changing our supply chain model significantly—more/less in-house, new supply chain partners, more supply chain partners, etc.

- We want to do this right from the beginning

- We don’t want to invest in building our own solution, expanding our IT department, rolling out the paper process for new people

- We know we will be going for a big goal in future (ISO, 8D, 510K, merger) and we want something in place sooner rather than later

Growth

- We’ve doubled our team in the past six months

- We have five new products coming out next year

- We’ve won a significant contract and now need to execute

- We’ve acquired a company

Gross Inefficiencies

- Everyone went #WFH in March and everything now takes too long or is too hard

- We need to streamline and speed up product development

- Quality resolutions are time-consuming

- People are doing the same things repeatedly and disconnected from each other

Upcoming NPDI

- We plan to commercialize our first product in nine months

- We have a second product effort starting

- We are launching a new product line

- We are expanding into a new market

Compliance

- We have a filing or audit in six months and must ensure compliance

- We failed an audit, standard, or regulation

Take Action Now or Later?

You should be ready to have conversations as to if PLM is a priority project or if your company can wait. The right time to implement PLM is unique to your company culture, ways of work, product specifics, and business goals. Sometimes, even though you need a solution, the time isn’t right. Twenty percent of our new customers choose Arena after multiple discussions with us over months or even years.

If you marked only one timing driver, you’ll want to look at the other projects vying for resources and their timing drivers. You may need to construct a business needs statement and capture the cost of how you do product work today. Inefficiencies, inaccuracies, missed communications, and lack of collaboration can add up to excessive costs. If you are currently running product management on spreadsheets, jump over here to explore the risks.

If you have two or more drivers for PLM now, this is the time to move PLM to the top of the list. Congratulations—with two or more drivers, you must have exciting product work planned that can leapfrog you over competition or push you into new markets. Below are some great resources to start team conversations about your possible future.

- How Much Can You Save With Cloud PLM?—Check out our interactive calculator

- Proactive pain avoidance—Innovators Need Intelligent BOM Management

- Growth—Innovation for a New Era

- Gross inefficiencies—Getting to Milestones Practical Guide

- Upcoming NPDI—Connecting Teams and Data in NPDI

- Compliance—Strong Design Controls Simplify Compliance

- Product Lifecycle Management FAQs