Webinar Registration: The P2G Advantage

Webinar Registration: The P2G Advantage LEARN MORE

Retail is restructuring and it’s not the pandemic, it’s the future

Melissa Valentine, Vice President, Sales (North America)

By Melissa Valentine | Director of Retail, Locus Robotics

Retailers have been going through quite the metamorphosis from brick & mortar to e-commerce, to omnichannel, to micro-fulfillment centers (MFC), to rapid delivery, to BOH fulfillment, to a pandemic-caused shift that accelerated all digital transformation using retail automation and devastated those who were not ready.

Some are holding on to “the return to normal” and looking forward to the day we can all resume life as we knew it. However, the changes retailers are implementing are not temporary, they’re permanent. Digital transformation through retail warehouse automation has been on every retailer’s long-term plan, the pandemic simply moved up the timeline by several years.

Retail is experiencing new demand at faster rates

Online retailers are greatly enhancing the customer shopping experience with retail automation, offering easy delivery/pickup options and free returns, and customers have a multitude of options within seconds to compare before making a purchase.

The co-owner of clothing brand GANNI shared the change in priorities with Forbes after losing one third of sales overnight: “In light of COVID-19 we will change our priorities. We will accelerate the digital strategy, reduce samples, implement a virtual showroom and break with the traditional fashion calendar.”

Our increasingly global, increasingly virtual world is also driving new demand at faster rates. Forbes named influencer-driven sales as one of the top 5 retail trends for 2021. Customers are getting their recommendations from social media influencers and celebrities, often creating shifts in the products that are trending. Retailers are then faced with both an excess of previously popular products as well as needing to replace inventory to make room for new demand.

The challenge now for retailers is to find both structure and flexibility for those unexpected changes going forward.

Restructuring and designing for flexible order fulfillment

Micro-fulfillment centers have caught national attention as companies race to find faster productivity and fulfillment rates. They’re finding retail warehouse automation significantly improves throughput without increasing the labor workforce. Their success is building strong cases for both greenfield and brownfield developments.

Grocers are a great example; some early adopters are building their entire micro-fulfillment operations beginning with a retail robot solution. Despite having some of the lowest margins in retail, despite the costlier overhead of being closer to customers, the ROI is proven.

It’s also true for those integrating retail robot automation into an existing facility and operations. According to Progressive Grocer, the initial investment and timeframe for integrating warehouse robots into an MFC are less intense than those of a traditional fulfillment center. Some of the most profitable solutions don’t even require operations or productions to halt during installation, reducing ROI to months and weeks in many cases.

Smaller retailers are finding homes in multi-tenant distribution centers where the costs for a retail automation solution are shared, further accelerating the ROI. The flexibility of an on-demand solution is especially beneficial to retailers avoiding large capital purchases because the costs are more often applied as smaller monthly operational expenses.

Options for retailers

The decision to automate retail warehouse operations has to be affirmative, and there are several opportunities to integrate robots that retailers are evaluating and implementing. Large decision factors will narrow down that list including cost, size, infrastructure requirements, and operational downtime during installation. For example, robots that run on a grid require massive infrastructure planning and changes, and in most cases cannot be installed in the same space that current operations are running.

Robotic arms can pick products effectively but cannot be the only solution implemented; they require a hybrid automation solution, working in tandem with conveyor belts and other robots or machines to fulfill orders, which is very costly. For these reasons, many companies are turning to a multi-bot solution that requires little infrastructure changes, can be installed in working operations, and multiplies the productivity of workers while returning an ROI within months instead of years.

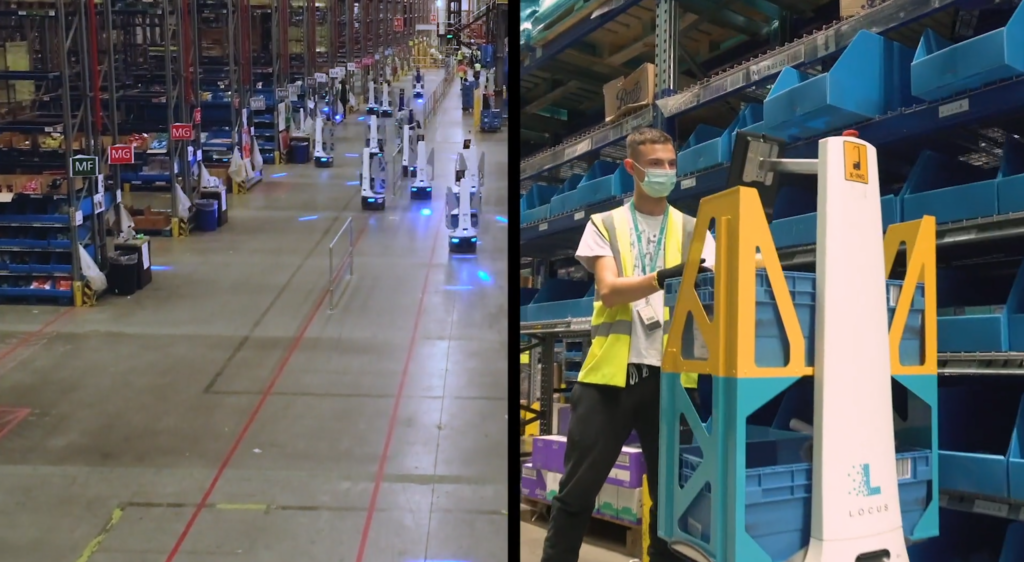

The multi-bot solution

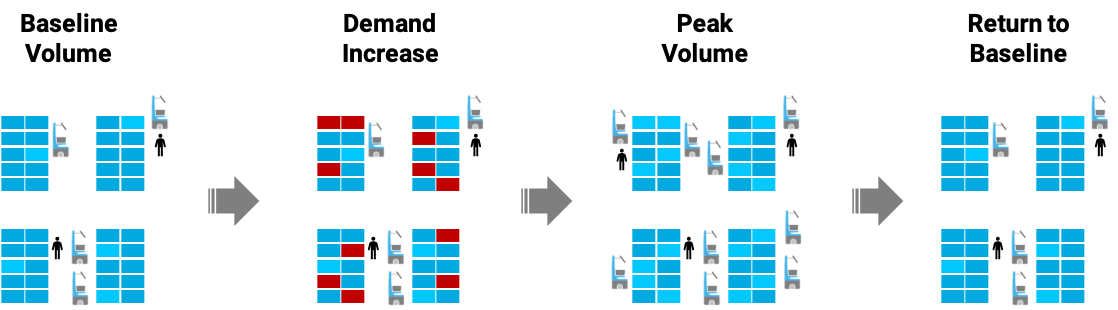

The multi-bot solution uses autonomous mobile robots (AMR) and runs on a Robots-as-a-Service (RaaS) model, essentially removing the up-front capital costs that cripple many plans to automate. Stores and warehouses monitor their demand in real-time and place an order for additional warehouse robots when volume increases, then send them back to return to the baseline operation. The fleet of robots is also safe enough to operate in hybrid environments, fulfilling orders from a stockroom or traveling between aisles to the many locations of goods.

A multi-bot solution is so flexible, it is capable of high performance in hybrid human-centric environments as well as dark microfulfillment (MFC) or ecommerce fulfillment (EFC) centers. Being highly portable as well, it does not limit retailers to keep unbusy robots in a particular store site as robots can be moved between multiple sites based on demand. This power of flexibility strengthens operations to weather through the most unexpected demand increases or changes; it future-proofs the entire operation.

Small and large retailers reap the benefits of a multi-bot solution to solve some of the most difficult problems including order accuracy, training, and social distancing. Store associates and warehouse workers express positivity and excitement about their robot coworkers and experience improved personal job performance as their order accuracy reaches near-perfect rates. In current pandemic conditions, a multi-bot solution provides social distancing measures as part of its design, maintaining a grocer’s high productivity while complying with CDC guidelines.

Watch what executives and managers are saying about the Locus multi-bot solution in their operations. IT integration teams from various companies also offer their perspectives on deploying a multi-bot solution. While the future of automated retail fulfillment began several years ago, the coronavirus pandemic has accelerated the timeline for requiring robotic automation to give grocers a chance to emerge strong in a highly saturated, highly affected market.

About the Author

Melissa brings over 20 years of experience working with global retailers and brands to Locus. Prior to joining the Locus Sales team in 2019, Melissa spent 5 years helping customers solve complex supply chain challenges, via enterprise software and consulting services at Blue Yonder (JDA) and o9 Solutions. Melissa has a tenured career delivering sales results in high-growth companies as well as extensive expertise in Omni-channel Retail and Supply Chain. She builds long-term consultative relationships with her customers and partners. Melissa holds a BA from Washington University in St. Louis, and a Master’s in Counseling from Tulane University.