In his book “Have a Little Faith,” Mitch Albom shares the following story from a sermon given by Rabbi Albert Lewis in 1975:

“A man seeks employment on a farm. He hands his letter of recommendation to his new employer. It reads simply, ‘He sleeps in a storm.’

“The owner is desperate for help, so he hires the man.

“Several weeks pass, and suddenly, in the middle of the night, a powerful storm rips through the valley.

“Awakened by the swirling rain and howling wind, the owner leaps out of bed. He calls for his new hired hand, but the man is sleeping soundly.

“So he dashes off to the barn. He sees, to his amazement, that the animals are secure with plenty of feed.

“He runs out to the field. He sees the bales of wheat have been bound and are wrapped in tarpaulins.

“He races to the silo. The doors are latched, and the grain is dry.

“And then he understands. ‘He sleeps in a storm.’”

The moral of the story, as Rabbi Lewis states at the end of his sermon, is that if you’re proactive about taking care of the important things in life, “our lives will not be cursed with the aching throb of unfulfilled business.”

This sermon got me thinking: If the person in this story had been hired as a supply chain executive, what proactive actions would they have taken to be able to sleep through a supply chain storm like the one we’ve been experiencing the past two years?

In other words, what “unfulfilled business” would they have taken care of?

Here are my recommendations:

Map Your Supply Chain

A key component of supply chain risk management is supply chain mapping – i.e., knowing where the manufacturing/production facilities of your suppliers (and their suppliers) are physically located, and which parts or materials are manufactured/produced at each location.

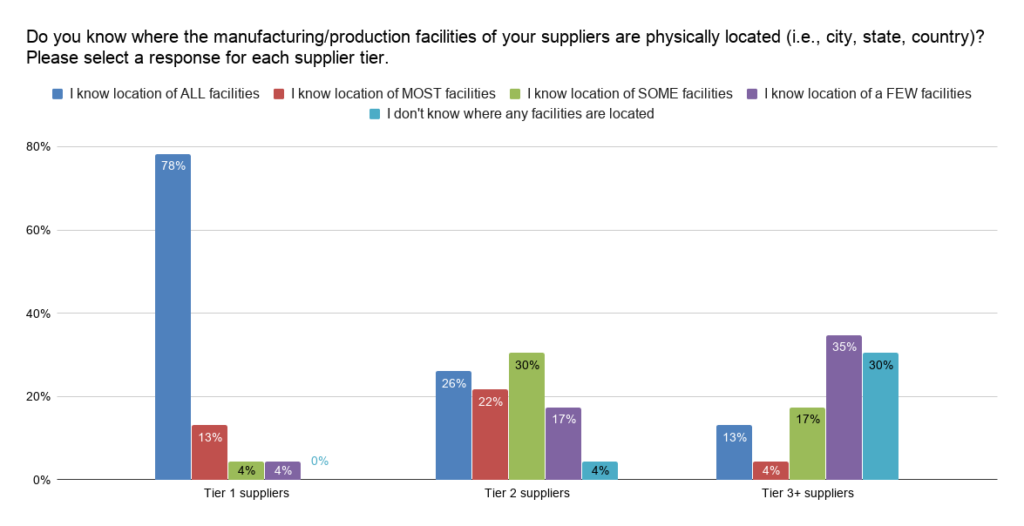

In March 2020, we asked members of our Indago supply chain research community — who are all supply chain and logistics executives from leading manufacturing, retail, and distribution companies — about their supply chain mapping experience and capabilities. As expected, our members have the most visibility to the physical locations of their Tier 1 supplier facilities, with 91% saying they know where ALL or MOST of them are located. In contrast, only 17% said they know where ALL or MOST of their Tier 3 supplier facilities are located.

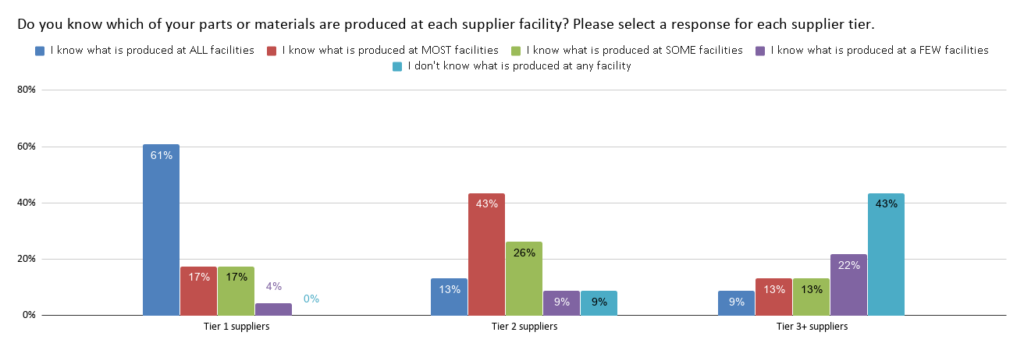

Similarly, when it comes to knowing which parts or materials are produced at each supplier facility, the best visibility is with Tier 1 suppliers (61% know what is produced at ALL Tier 1 facilities compared to just 9% that know what is produced at ALL Tier 3 facilities).

Ask yourself these questions: Do you know where the manufacturing facilities of your suppliers (and their suppliers) are physically located? Which parts are manufactured at each location? Do you track the history and frequency of disruptions that occur at each facility and geographic region, due to either natural forces (hurricanes, floods, earthquakes, etc.) or other factors (labor strikes, power outages, quality issues, etc.)?

If your answer is “no” to most of these questions, then it’s only a question of time before you get blindsided by a supply chain issue or disruption. Start mapping your supply chain today or be prepared to pay a big price down the road.

For more insights on this topic, see “VF Corporation: Supply Chain Mapping.”

Develop Digital Twin of Your Supply Chain

Mapping your supply chain is not enough; you also need a way to model and simulate different “what if?” scenarios, and that’s where developing a digital twin of your supply chain comes in.

A “Supply Chain Digital Twin” is a digital/software representation of your physical end-to-end supply chain. For example, as reported by Jennifer Smith in the Wall Street Journal, “Unilever is building virtual versions of its factories, using data streaming from sensor-equipped machines to create digital models that can track physical conditions and enable testing of operational changes.”

In a Talking Logistics guest commentary, Chris Jones from Descartes adds, “A digital twin — the creation of a virtual, but dynamic, representation of your operations — is a powerful approach to better understand how it works today or could work in the future. With a digital twin, an organization can monitor performance, predict the impact of changes, identify areas for improved productivity or customer service and evaluate new operating models.”

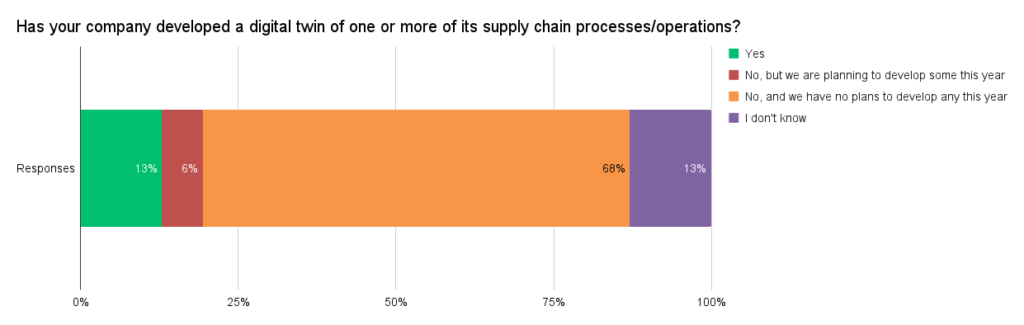

Unfortunately, many companies still lack this capability. In an Indago survey we conducted in February 2020, more than two thirds of our member respondents (68%) said that their companies are not using supply chain digital twins.

Our survey revealed various challenges to implementing a supply chain digital twin (see Indago report, available to members only). Nonetheless, the supply chain executives in our research community recognize how important this capability is becoming, as this member commented:

“As company operations become more complex, digital twins become a ‘must have.’ Companies with simpler operating environments could delay implementing digital twins but will likely adopt them in the future due to increasing competition and operating standards.”

Enable Real-time Visibility to Supply and Demand

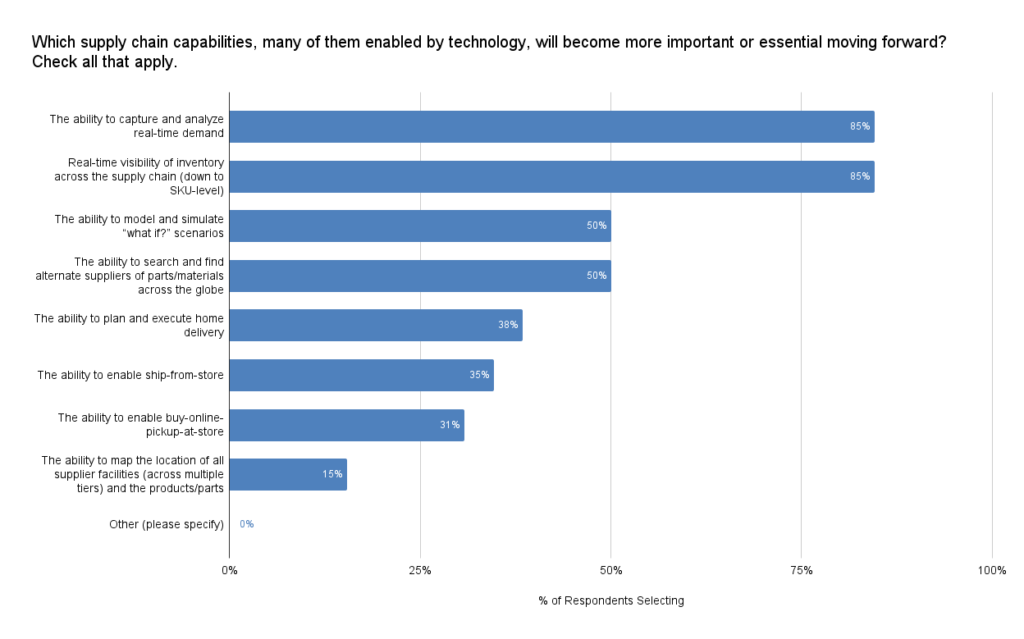

What supply chain capabilities will be most important moving forward? We asked our Indago research community that question back in August 2020 and here’s what they said in a nutshell: Having real-time visibility to demand and supply in order to respond quickly and efficiently to changing conditions, and the ability to model and simulate different scenarios ahead of time in order to proactively prepare for whatever lies ahead.

In short, once you’ve mapped your supply chain and developed a digital twin of it, you need real-time data about orders, shipments, inventory, and other inputs to continuously analyze whether you’re still on track to meet your objectives and to determine the best corrective actions to take when exceptions occur.

Visibility by itself, however, is not enough. Yes, having access to data you didn’t have before is powerful — but only if you do something with it, which is where supply chain software applications (like transportation management systems) with optimization and automated process execution capabilities come in.

Establish Vested Relationships with Strategic Trading Partners

Companies need to approach their business relationships with suppliers, carriers, logistics service providers, and other trading partners with a different mindset moving forward.

The focus should not just be on getting to a deal or a contract; the focus also needs to be on building collaborative relationships.

One of the thought leaders in building collaborative business relationships is Kate Vitasek from the University of Tennessee. She and some colleagues have written several books on this topic, including “Getting to We: Negotiating Agreements for Highly Collaborative Relationships.” Here is a quote from the book that describes this shift in mindset nicely:

“More and more, business success depends on strategic relationships built for an ever-dynamic and interconnected world that will endure long after ‘the deal is done.’ For many organizations, this ongoing relationship is as important as the deal itself. The focus needs to be on developing evolving and mutually beneficial relationships that create shared value, solve mutual problems, and get both parties to a place of ‘we’ rather than the usual ‘us vs. them’ tug of war.”

In short, it’s about getting away from a “What’s in it for me?” mindset (an “I Win, You Lose” mindset) to a more collaborative “What’s in it for We?” mindset.

How can companies and their trading partners “Get to We”? It’s not easy, and it’s not for every business relationship, only those that are truly strategic in nature. But as you might imagine, it requires trust, transparency, honest communication, and courageous leadership to think and act differently.

As Dr. Thomas Lieb, Chairman of the Supervisory Board of Hellmann Worldwide Logistics and former CEO of Schenker, commented in a research study we conducted in partnership with Transporeon in late 2021, “Most importantly, what we have learned over the past 20 months is that we need to build trustful and reliable relationships with all stakeholders in the supply chain.”

—

I don’t believe a supply chain executive can fully sleep through a supply chain storm, but by taking the actions above, by taking care of this unfilled business, they can certainly sleep with less worry and nightmares in the storms to come.