What is the bullwhip effect?

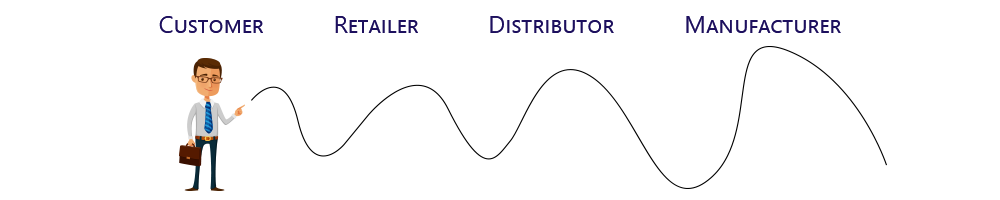

Imagine a person having a long whip in his hand, and if he gives a little nudge to the whip at the handle, it creates little movements in the parts closest to the handle, but parts further away would move more in an increasing fashion.

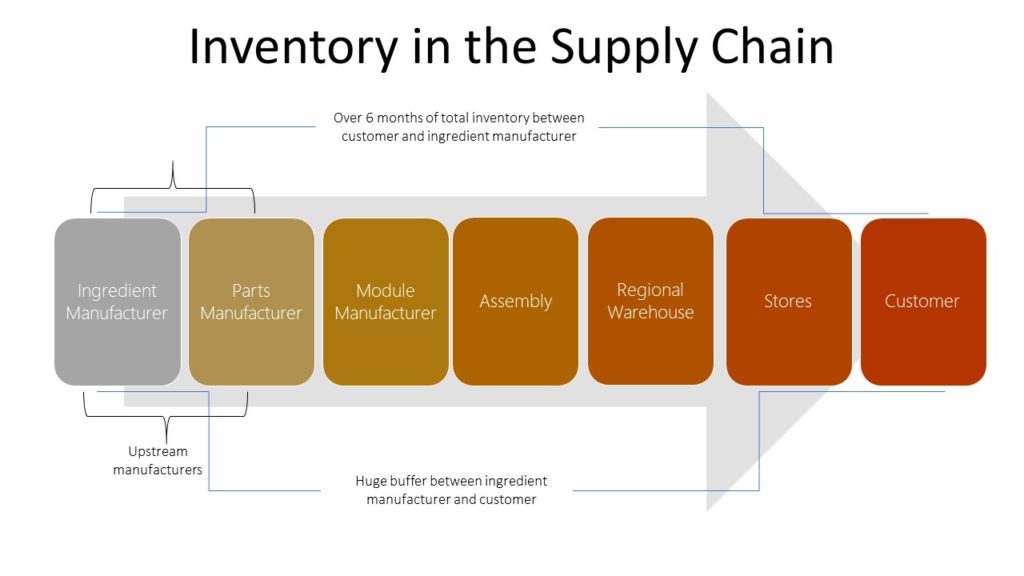

Similarly, in the supply chain world, the end customers have the whip handle and they create a little movement in the demand which travels up the supply chain in an increasing fashion. As we move away from the customer, we can see bigger movements. On average, there are six to seven inventory points between the end customer and raw material supplier (as shown below in figure 1). Everyone tries to protect themselves from stock-out situations and missed customer orders, by keeping extra inventory to hedge against variability in the supply chain. Hence, huge buffers of inventories up to six months can exist between the end customer and raw material supplier. This bullwhip effect ultimately causes the upstream manufacturers to have increased uncertainty which results in lower forecast accuracies leading to higher inventories.

To understand how to minimize the bullwhip effect. Let’s take a step back and look at the definition of the bullwhip effect.

Definition of the bullwhip effect

The bullwhip effect is a concept for explaining inventory fluctuations or inefficient asset allocation as a result of demand changes as you move further up the supply chain. As such, upstream manufacturers often experience a decrease in forecast accuracy as the buffer increases between the customer and the manufacturer.

[Read More: 7 Things You Must Know About Demand Sensing]How Do You minimize the bullwhip effect?

Every industry has its own unique supply chain, inventory placements, and complexities. However, after analyzing the bullwhip effect and implementing improvement steps, inventories in the range of 10 to 30 percent can be reduced and 15 to 35 percent reduction in instances of stock out situations and missed customer orders can be achieved. Below are some of the methods to minimize the bullwhip effect.

-

- Accept and understand the bullwhip effect

The first and the most important step towards improvement is the recognition of the presence of the bullwhip effect. Many companies fail to acknowledge that high buffer inventories exist throughout their supply chain. A detailed stock analysis of the inventory points from stores to raw material suppliers will help uncover idle excess inventories. Supply chain managers can further analyze the reasons for excess inventories, take corrective action and set norms.

-

- Improve the inventory planning process

Inventory planning is a careful mix of historical trends for seasonal demand, forward-looking demand, new product launches and discontinuation of older products. Safety stock settings and min-max stock range of each inventory point need to be reviewed and periodically adjusted. Inventories lying in the entire network need to be balanced based on regional demands. Regular reporting and early warning system need to be implemented for major deviations from the set inventory norms.

-

- Improve the raw material planning process

Purchase managers generally tend to order in advance and keep high buffers of raw material to avoid disruption in production. Raw material planning needs to be directly linked to the production plan. Production plan needs to be released sufficiently in advance to respect the general purchasing lead times. Consolidation to a smaller vendor base from a larger vendor base, for similar raw material, will improve the flexibility and reliability of the supplies. This, in turn, will result in lower raw material inventories.

-

- Collaboration and information sharing between managers

There might be some inter-conflicting targets between purchasing managers, production managers, logistics managers and sales managers. Giving more weight to common company objectives in performance evaluation will improve collaboration between different departments. Also providing regular and structured inter-departmental meetings will improve information sharing and decision-making process.

-

- Optimize the minimum order quantity and offer stable pricing

Certain products have high minimum order quantity for end customers resulting in overall high gaps between subsequent orders. Lowering the minimum order quantity to an optimal level will help provide create smoother order patterns. Stable pricing throughout the year instead of frequent promotional offers and discounts may also create stable and predictable demand.

[Read More: Demand Forecasting: The Art and Science That Keeps You Guessing]When was the last time you and your company paid detailed attention to the bullwhip effect? Every industry is unique with its own sets of complexities, challenges, and opportunities. Get in touch with a supply chain expert at Arkieva: info@arkieva.com or visit www.arkieva.com for personalized supply chain solutions for your company.

Enjoyed this post? Subscribe or follow Arkieva on Linkedin, Twitter, and Facebook for blog updates.