The first job I had at the beginning of my career was in the Materials Handling and Engineering department. As a part of my job I was responsible for Forklift and Material Handling equipment planning.

To help me understand this area better I took the Forklift driver training course just like anyone else would have to do. I was able to drive the truck and load and unload pallets from trucks and into and out of warehouse storage locations.

While I wouldn’t trust myself to drive a forklift these many years later I was reminded of the importance of forklift driver training and safety this week when I saw a short video of an absolutely horrendous forklift accident.

This is the busiest time of the year in warehouses all over the world as companies look to ship all possible goods out of their warehouses and to their customers. The push to handle enormous volumes and to ship to customers faster than ever before means that there is a lot of pressure on warehouse personnel to move quickly. And with speed, amongst other factors, the risk of accidents in these fast paced warehouses is bigger than ever.

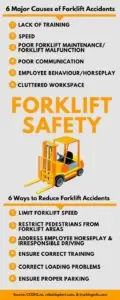

In the U.S. alone there are over 850,000 forklift trucks. Amazingly there are almost 100,000 forklift accidents every year as well. That is there are more than 1 in 10 accidents per forklift in the U.S. each and every year. (Source: https://www.oshasafetymanagement.com/blog/forklift-safety-infographic/). That is absolutely incredible, and not in a good way.

What concerns me is that I am sure that these statistics are understated. I have walked up and down hundreds of racking aisles in dozens of warehouses and you almost always see examples where the uprights of the racking have been bent or hit.

Yet the number of these accidents that are actually reported is far less than the number of damaged racks that you can see.

Of all those accidents almost 100 result in fatalities which is truly tragic. That was my first thought as I watched the following video. The damage to the warehouse and inventory is one thing, but the person driving the forklift, as well as other people in the area, could at the very least have sustained life long injuries and disabilities if they didn’t actually lose their lives.

While I titled this article the “Worst Forklift Accident Ever” having watched this video what concerns me is that is most likely not true. I am quite sure that there are even more horrific accidents that have occurred. The loss of a single life, and the occurrence of one accident, should be enough to raise the alarm bells in every warehouse in every company in every country around the world.

Safety cannot be compromised for ANY reason. Profit, speed, and customer service must all take a back seat to safety.

While regular equipment maintenance and performing forklift repair whenever required is absolutely necessary, the majority of forklift accidents can be avoided with proper education and training. As noted in the following infographic all of the causes of these accidents are avoidable.

The most common accident involves the forklift actually overturning. When you consider that a forklift truck can weigh as much as 9000 pounds it is easy to imagine the sheer terror a forklift driver, or anyone in the immediate area, would experience when a forklift turns over.

Forklift operators and all warehouse personnel must understand that forklifts are not toys. Even though these are common warehouse vehicles they require proper training and certification. And this training should be more than just learning how to physically drive a forklift. It should include education on the physics and science involved with the design of the vehicle, load management, weight ratios, centre of gravity concepts and leverage points.

And this training must be regularly tested for compliance and either recertification or decertification.

Further proper Forklift operation must be a condition of employment. There needs to be a zero tolerance policy in place. If there is a minor accident then the employee gets a warning and is advised that if this is repeated they will immediately lose their job.

My supposition here is that Management has taken all necessary measures to prepare, provide, conduct, monitor, track, measure and report on training courses and tools and performance management. Without this in place then Management is at fault right from the start.

Conclusion

Whether we realize it or not we are all putting pressure on some forklift driver somewhere in the Supply Chain to drive a little faster in a warehouse or Distribution Centre so that we can get our goods quicker.

But getting our stuff faster, or at a lower cost, is never worth it if it causes someone to do their job in an unsafe manner. We must all demand that the people doing this work for our collective benefit are given the appropriate training and education and are held accountable to that safety standard.

Safety is first. It is not a catch phrase. It must be the reality.

Safety comes first above all other objectives!

Howdy! I truly like your endeavors. Continue to share such useful stuff. Truly astonishing. Much thanks to you.