How To Optimise Your eCommerce Warehouse

We don’t need to tell you how critical warehousing and shipping are to your eCommerce business. Timeliness and accuracy of orders affect customer satisfaction and therefore retention, and set the rate of returns and by proxy profitability; efficiency in putaway and storage affects the amount of square footage you need to lease, insure, maintain, and staff.

None of this can happen if your warehouse is not optimised. Our team has identified these critical steps to ensure this, maximising your efficiency and profits.

1. Optimise Warehouse Layout and Storage

Warehouse slotting is the process of identifying the most appropriate storage location for each product in your inventory. Slotting optimisation allows warehouse workers to pick orders faster and, consequently, helps to enable next-day or same-day delivery, which is a popular option in e-commerce. This type of e-commerce warehouse layout also ensures you’re making the most out of your warehouse storage space.

Why you should choose a WMS to help:

It’s possible to optimise warehouses manually, but this process requires the analysis of a great deal of data - at least a full year’s worth, including seasonality and projected inventory growth. We recommend investing in an optimisation system to save your valuable time for working on other important tasks.

Critical Considerations:

Many warehouses make the mistake of calculating only the storage space that they need, without adequately taking into account other warehouse operations; remember to account for the following, as well as the staff needed to operate them:

- Receiving (including unloading, quality control checks, and labeling)

- Storage (plan on extra storage space to anticipate growth)

- Forward staging (incorporate space for at least one day’s worth of orders)

- Shipping (including not just pack and ship, but also quality control, labeling, and breaking down larger pallets)

- Extra area for returns and “dead” stock

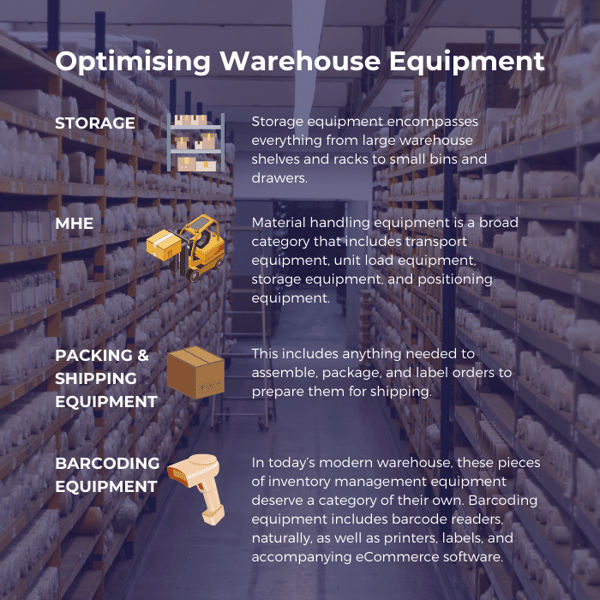

2. Consider Essential Equipment

Warehouse equipment might be essential depending on your products, volume, and business model. Generally speaking though, most eCommerce warehouses and fulfillment centers have the same basic goals: maximise space, increase efficiency in the flow of goods, improve visibility, and do it all in a way that’s safe for staff and for your goods.

There are four basic kinds of warehouse equipment, based on warehouse functions:

Storage

Storage equipment encompasses everything from large warehouse shelves and racks to small bins and drawers.

Material Handling Equipment

Material handling equipment is a broad category that includes transport equipment, unit load equipment, storage equipment, and positioning equipment.

Packing and Shipping Equipment

This includes anything needed to assemble, package, and label orders to prepare them for shipping.

Barcoding Equipment

In today’s modern warehouse, these pieces of inventory management equipment deserve a category of their own. Barcoding equipment includes barcode readers, naturally, as well as printers, labels, and accompanying eCommerce software.

3. Embrace Automation

When you consider that eCommerce has already made the browsing and buying process much more efficient through automation, it makes sense to continue streamlining throughout the process to product picking and shipping.

Automation does not have to be a complete change to your warehouse - the best automation centers around small investments in single-task machines:

- Barcode scanners can help streamline picking and eliminate cycle counts while improving accuracy.

- Conveyor belts can safely move heavy containers from one area to another, eliminating the need to carry stock and thus putting less strain on employees. Alternatively, lift-trucks and pallet jacks can realise jobs quickly, easily, and safely.

- A laser DIM-weight scanner can automatically calculate measurements of shipments, ensuring accuracy and speeding up the shipping process.

- Machines for mundane, repetitive tasks, such as breaking down pallets, can save time and therefore money.

These machines have a break-even point that occurs in months, as opposed to years. Thus, investing in this kind of equipment piecemeal from the beginning can incrementally improve ROI.

4. Optimise Pick Paths

Are you worried about the optimal pick path? That’s the first problem - a WMS would be far more effective at doing this than you!

Before the rise of e-commerce, warehouses and distribution centers were used to processing bulk orders. Now, they are dealing with smaller orders and even individual items, requiring a more efficient picking strategy.

Good warehouse management software is best at picking optimised pick paths for a warehouse, because it is based on mathematical logarithms. Here are some best practices to abide by, no matter if you are creating pick paths by hand or automation:

- There are different order picking methods (wave picking, batch picking or zone picking); know the differences so you can make educated decisions

- Orders should be fulfilled in such a way that individual items in one area are picked before moving to the next area

- Items that are often purchased together should be stored near each other

- Picking order should be linear, with warehouse employees completing their picking run at a location close to the final shipping area

- REMEMBER - if warehouse employees have to backtrack or frequently cross paths, it’s going wrong!

Cluster-picking is an easy method to start with if you want to optimise your warehouse for e-commerce. It’s a cost-efficient strategy that focuses on the picking of items instead of orders. In this method, a single picker collects multiple orders at one time and places them in separate totes to avoid errors. Cluster-picking decreases the travel time of workers, which accelerates the picking process and offers the potential to meet tighter delivery times.

5. Establish Warehouse Guidelines

At this stage, it’s time to start drawing up some warehouse policies and guidelines for your workers. Proper pick paths are just the start - you need to consider safety procedures, workflow, and quality control/order accuracy.

Establish policies now for quality control and order accuracy, because these will form the core of your employee training.

- Safety procedures: Now is the time to establish, in writing, the safety procedures employees will need to follow.

- Workflow: In an ideal world, the entire process from picking to packing to shipping would be part of a single, well-documented workflow. Much of this workflow will be dictated by your setup.

- Quality control and accuracy: Establish guidelines for quality control at each stage of ordering. Start with receiving: What is considered an acceptable level of breakage before an order is returned? How will you ensure order accuracy? How will returns be processed?

- How will order accuracy be ensured? How is breakage and spoilage reported? Will each item be checked (inefficient) or will you use statistical checking?

- Shipping: Are all items present in the order? Are they packed appropriately? Does the address on the label match the address on the original order? Is the method of shipment (Ground, Air, etc.) accurate?

Note: much of this will need to be determined by warehouse policies, such as how often do pick waves occur; how much inventory needs to make it to forward staging, and how often; when should equipment be put away, and where.

Try to see the workflow from your employees’ point of view, then maximise their energy and minimise confusion by employing a WMS to streamline this process.

6. Staff Training and Optimisation

Training is not just about imparting knowledge: it is about giving your employees key skills they will need to work quickly and efficiently. Resources spent on training will pay for themselves over time in speed, efficiency, fewer mistakes, and a safer work environment.

By optimising labour and being able to use data to anticipate seasonal fluctuations, you can ensure that you are caught neither short-handed or over-staffed.

7. Using the right warehouse management software

If you aren’t joining them, you are being beaten by them! An excellent WMS will remove a lot of the donkey work by embracing automation and streamlining systems by integrating with ERPs and workflows.

“With the increase in eCommerce and multi-channel fulfillment, many companies have realised that their existing system may fit their brick-and-mortar fulfillment environment, where the lowest level of picking is normally a case, but it’s a different set of WMS needs when you are doing many individual item picks for e-commerce.”Dwight Klappich, Research Vice President for Gartner

There are many offerings in this category, at many different price points, and with different capabilities, but here are some basics you should definitely look for:

The WMS basics you will need:

- Inbound receiving and inventory control (“door-to-door”)

- Pick/Pack/Ship workflow management with directed, optimised workflows and schedule plans

- User-defined reports reflecting your own KPIs

- Key alerts

- Easy integration through APIs

- Scalability

Staying committed to a legacy WMS in your warehouse can result in bottlenecks and delays in fulfilling a high volume of orders. This is because old WMS solutions have limited capabilities, including the inability to utilise modern warehouse technologies.

To optimise your warehouse for e-commerce, it is strongly recommended to upgrade to an advanced WMS system that is equipped to work well with modern technologies such as mobile devices, dimensioners, and others. Leveraging new technologies will help you optimise warehouse processes and enable you to take on some of the key challenges associated with e-commerce.

8. Integrate your systems

The integration allows diverse business systems to share data seamlessly, opening up a number of opportunities for cutting costs, increasing efficiency, and reducing errors.

Which systems need to be integrated?

- Channel software/shopping cart software/POS

- Shipping scheduling software

- Accounting systems

- Ordering systems

- Existing ERP solutions

9. Define KPIs and establish data collection

This is a great indicator for optimisation, and having the right warehouse metrics and KPIs (Key Performance Indicators) will help to identify bottlenecks, plan out warehouse operations, and measure overall customer satisfaction.

There are many KPIs you should consider tracking for optimal warehouse management, and a good warehouse management solution should be able to gather all of these easily.

Here are four warehouse KPIs to start with:

- Order lead time: The total time it takes to fulfill an order, including picking, packing, and shipping.

- Inventory turnover: The frequency with which you sell out your entire inventory (or a given volume of inventory).

- Rate of return(s): The frequency with which items are returned. Customer service should also record the reasons for return, as this will suggest where problems might live: receiving, picking, quality control, etc.

- Transportation cost per package: The total cost to move an SKU or order, including the cost of labour, handling equipment, and safety equipment, etc. This metric makes it obvious how important an efficient warehouse layout with a good pick path is.

10. Optimise Your Reverse Logistics Process

In the past, many companies didn’t have much interest in optimising their reverse logistics process, which made it difficult for them to efficiently and affordably manage returns in today’s e-commerce age. Providing a hassle-free return experience has become crucial in earning customer satisfaction. Hence, it’s imperative to optimise the reverse logistics process.

11. Stay Technologically Savvy

New products, new technologies, and new business models mean that what worked a few years ago might not be optimal today.

As your customer evolves, it is a critical mistake to not only lag behind, but to anticipate their needs and preemptively adapt accordingly.

Having a flexible WMS that can integrate and offer options for future solutions like machine learning and automation is no longer on the wishlist, but an essential in order to cope with sudden changes in demand and interface with new technologies as they arise to maximise your workflow.

Download our Warehouse Optimisation Checklists to get started, and see how you track against your own KPIs:

OR: See how you compare wo industry benchmarks with our Benchmarking Checklist:

TAGS

- WMS (50)

- Warehouse Best Practice (46)

- Implementing a WMS (29)

- Managing your warehouse (19)

- Omni Channel (18)

- eCommerce (18)

- Blog (16)

- Supply Chain Best Practice (16)

- Mid-Level (8)

- Customer Journey (7)

- Warehouse optimisation (7)

- General Tips (5)

- Industry General (5)

- Information (5)

- managing your Supply Chain (5)

- saudi arabia (5)

- Trends (4)

- smart warehouse (4)

- 3PL (3)

- News (3)

- ERP (2)

- Entry-level (2)

- ROI (2)

- Case Study (1)

- OMS (1)

- Picking (1)

- Press Release (1)

- Solution-Specific (1)

- Transport Management System (1)

Take A Look At The Results Of A Successful WMS Implementation.

See how Tarsus Distribution, in collaboration with SCJ boost overall efficiency by 60%