This is an excerpt from Medically Necessary, a health care supply chain newsletter. Subscribe here.

The transition: The coronavirus pandemic has sent health care distributors on a roller-coaster ride, but now they’re preparing to shift operations into a post-pandemic mode.

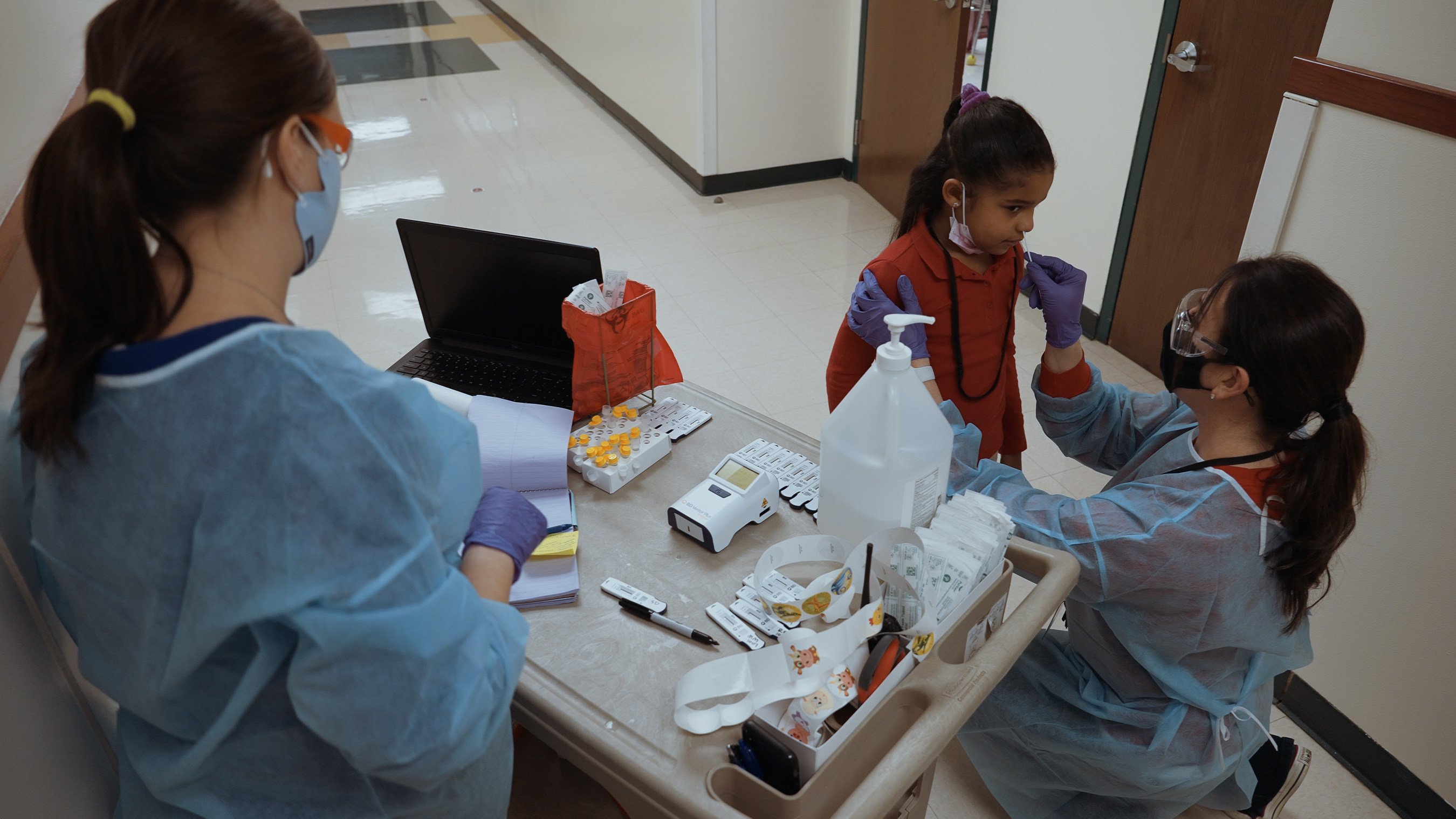

In 2020, companies had to quickly scale up activities directly responding to the pandemic, such as supplying personal protective equipment, vaccines and COVID-19 tests. They also had to scale down activities serving other aspects of health care, such as visits to doctors’ offices or elective surgeries.

Now, COVID-19 cases in many countries are declining, and companies in the health care supply chain are trying to figure out how to successfully switch back.

Scale up: Health care companies made large investments in physical infrastructure last year, often with help from the federal government, to respond to the coronavirus pandemic.

Now, they’re deciding how to manage those investments as case numbers start to drop in the U.S.

The health care distributor McKesson custom built 3.3 million square feet of warehouse space for temperature-sensitive COVID-19 vaccines.

McKesson expects to continue distributing vaccines over the next year, but most of that work will happen in the spring of 2021.

However, at a Bank of America health care investor conference last week, McKesson CEO Brian Tyler said that the infrastructure is easy to maintain and positions the company to respond quickly if patients need booster shots in the future.

“The infrastructure has been built. It’s working quite effectively and we’re prepared to continue it as long as there’s a need for us to provide the service,” he said.

Cardinal Health, another major health care distributor, invested in new manufacturing capacity last year. The company increased North American production of syringes by 15 million units, gowns by 20 million units and masks by 150 million units.

At the same investor conference, Cardinal CEO Mike Kaufmann acknowledged increasing manufacturing capacity carries some risk but also makes the company’s supply chain more reliable.

“We’ve managed the risk. … We are able to fluctuate and move,” Kaufmann said. “We can’t be in a position to not have masks, gowns and syringes. We’re willing to step out and do some of those types of investments.”

The price and availability of PPE were unpredictable last year, making it hard to guarantee a profit in the short term. However, Kaufmann said he believes the recent infrastructure investments will help the business succeed in the long term.

“You have to do it in order to take care of your customers. It’s why we exist,” he said. “I think it’ll be choppy for a little while, then that will flush through and we’ll have a stronger supply chain and business when we’re all said and done.”

The medical device company Becton, Dickinson and Company — which has received orders for 1.7 billion syringes to help with vaccination efforts — partnered with the U.S. government on a $70 million expansion to a Nebraska plant producing syringes.

The expansion, intended to support the COVID-19 vaccination effort, won’t come online until the summer.

At the current pace, the global COVID-19 vaccination campaign could extend for years, according to a Bloomberg analysis. BD executives are in discussions with pharmaceutical companies to prefill syringes with COVID-19 vaccine, a project that could keep the company busy for quite a while.

“We were wondering [if] there was going to be a cliff of syringes into 2022. We see that demand … as being durable,” Dave Hickey, BD’s life sciences segment president, said on a recent conference call. “Things like booster shots … would just make that demand even more durable.”

But the company also says the syringe business is growing fast and investments in manufacturing capacity will pay off after the pandemic.

In December, BD announced a $1.2 billion investment in expanding manufacturing capacity for prefilled syringes.

That capacity, intended to help with future pandemics and a growing number of injectable drugs, won’t come online until 2023.

Scale-down: As cases of COVID-19 drop in the U.S., some pandemic-related activities will start to wind down, but the timing is difficult to predict.

The number of COVID-19 tests in the U.S. has fallen from about 2.3 million in early January to about 1 million in mid-May.

BD executives are still hoping to play a role in COVID-19 testing going forward, but it may not be the massive level of testing seen during the peak of the pandemic.

COVID-19 testing made up nearly 10% of BD’s revenue in the first three months of 2021.

The company has been expanding its portfolio of COVID-19 testing options, including a device that tests for flu and COVID-19 at the same time, which the company believes could be an important tool during flu season.

“We’re pulling all the levers we can to make COVID testing more sustainable as we think about the combined COVID and flu assay,” BD CEO Tom Polen said on a recent conference call. “We’re also working on the at-home test. That should have some ability to have sustainability in COVID testing. But clearly, it will come down.”

In financial filings, McKesson reported that COVID-19 tests, PPE sales and distribution of ancillary supplies for COVID-19 vaccines accounted for 20% of the company’s medical distribution segment revenues.

“As vaccines rise and COVID falls, there should just naturally be less demand for COVID test kits,” Tyler said at the Bank of America investor conference.

Comeback: As COVID-19 testing slows down, other areas of health care utilization have been increasing. That should more than make up for business lost due to the waning pandemic.

On a conference call, Kaufmann said demand for surgical products hit 95% of normal near the end of 2020. Rising case numbers in the U.S. drove demand back down to 90% in the first few months of 2020.

By the end of March, demand had bounced back to about 95%, and the company expects to reach pre-COVID levels over the next six months.

Masks and social distancing essentially eliminated the cold and flu season last year, leading to low levels of prescriptions. Now, drug distributors expect those drugs will start bouncing back.

As we look to the current situation and … with vaccines and a lower incidence of COVID-19 in many parts of the country, people will be scheduling these diagnostic procedures and getting referrals for physicians to treat conditions,” AmerisourceBergen CFO Jim Cleary recently said on a conference call.

New normal: Other parts of the health care supply chain simply won’t return to normal, according to Robert Rajalingam, president of U.S. medical solutions sales at Cardinal Health.

“We’re not trying to go back to the way things were before. We are taking this time to set our go-forward plan … and that might look a little different than it did a year ago,” Rajalingam wrote in an email.

After shortages during the pandemic, Cardinal expects that demand for PPE will remain slightly elevated compared to previous years.

Cardinal is planning to make its supply chain more geographically diverse and add more domestic manufacturing capacity. The company is also hoping for more collaboration with customers when it comes to sharing data about inventory and supply chain bottlenecks.

“Right now – and as we transition to a post-pandemic state – we’re making investments and enhancements across the supply chain,” Rajalingam wrote.

That includes improving the management of suppliers to ensure they can deliver necessary products. It also means expanding the company’s distribution network so Cardinal can get those products to customers.

Rajalingam said Cardinal plans to invest $50 million to add 1 million square feet to distribution centers across the U.S.