Walmart’s Eden and Verigo’s Pod Quality: Technology to Reduce Fresh Produce Waste in Supply Chains

Walmart is developing a technology worth $2 billion that inspects fruits and vegetables for defects and can accurately predict the exact date when it will spoil.

Walmart recently announced an intelligent quality management system is being used throughout Walmart supply chains and distribution centers to reduce waste and increase the quality of fresh produce.

The quality management system, called Eden, utilizes machine learning and temperature monitors to predict the freshness (ie. shelf life) of a variety of commodities, ranging from bananas to apples to tomatoes.

Eden aims to track freshness throughout the supply chain, which empowers informed decision making based upon the remaining freshness of a shipment of product.

The company says the technology, will save Walmart $2 billion over the next five years, mostly through a reduction in food waste.

It has already saved Walmart $86 million since it was deployed to its 43 food-distribution centers in January of last year, according to Parvez Musani, vice president of supply chain technology engineering at Walmart Labs.

“We are constantly looking at technology to serve our customers better,” Musani told Business Insider in an interview.

The technology will soon extend to the farms of Walmart's suppliers as well.

“We'll have drones flying over the farms” to monitor temperatures and other factors that determine the quality of the produce Walmart is getting from suppliers, Musani said.

The company said the technology will not replace workers, however, saying humans will always be involved in the process of determining food quality.

“The machines will just help speed things up,” Musani said.

Making supply chain decisions based on the freshness allows for optimal routing and rotation of fresh produce, which in turn will reduce waste and increase quality, which is a win for all stakeholders.

For example, if Eden sees that the temperature on a pallet of bananas has increased beyond an optimal threshold, the smart system can judge that the quality has degraded, and re-route that shipment to a closer distribution center or store.

The proliferation of technology to fight food waste (and increase the bottom line) has been long overdue.

The technology could also deal a blow to Amazon and Whole Foods, which has been facing customer complaints about the quality of its food produce.

Though Eden is an internal Walmart initiative, other companies provide similar products in the fight against food waste.

Read: An Inconvenient Truth About the Produce Supply Chain - Is New Tech The Solution?

Continuous Product Life Data, From Farm to Store

Verigo’s Pod Quality system operates on similar principles to Walmart’s Eden.

Pod Quality is the first temperature data logger smart enough to continually translate monitored temperature data into actionable freshness scores of produce in transit.

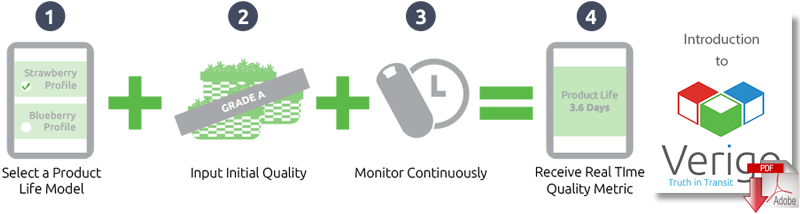

The key to the new Pod Quality monitoring device is the Quality Analysis engine it contains which translates raw sensor data into a single, actionable metric called Product Life.

This metric results from the analysis of a number of variables - commodity type, initial quality, and product temperature - and translates them to display the number of days of actual remaining shelf-life of that product.

Leveraging over 30 years of research from the USDA and studies with growers such as Driscolls and Berry World, Verigo has developed a growing library of unique Product Life Profiles which each characterize the degradation characteristics of a particular commodity, from Asparagus to Zucchini.

Verigo “smart” pallets will record, analyze, and continuously communicate temperature and remaining Product Life to any phone or tablet within ~15 meters.

At any point in the chain, staff can use the Verigo mobile app to view the quality and history of the products onscreen, without having to install any infrastructure of antennas, readers, or gateways. And as long as the phones and tablets used by staff have an internet connection, all data is automatically sent to the Verigo Cloud platform and is visible to management anywhere in the world.

How It Works

For the first time, it is now possible to do much more than monitor temperatures. With access to information about the shelf-life of individual pallets, stakeholders are empowered to make informed decisions that will reduce shrink by 20-40%.

Growers can now see when post-harvest, cooling, and packing operations are degrading shelf-life more than planned and take corrective action. Wholesalers can see the remaining life of pallets in the warehouse, and prioritize the inventory rotation and routing of pallets to minimize rejections. And receivers can begin evaluating the integrity of the products arriving at the dock before an inspection.

“This concept [smart shelf-life management] has been around for a long time, but it has never actually been developed and released as a usable product. Now that it’s here, we have an opportunity to change how quality is managed to prevent millions of dollars in shrink, and provide unprecedented quality to consumers. It’s truly a win-win.” states Verigo CEO Adam Kinsey.

Related: An Inconvenient Truth About the Produce Supply Chain - Is New Tech The Solution?

Verigo SC24/7 Resources

Pod Quality: Continuous Product Life Data From Farm to Store

This introduction paper provides everything you need to know about Pod Quality, including how it works, features, and benefits. Download Now!

Let’s Build a Smarter Food System

This comprehensive presentation provides an in-depth look into Pod Quality and covers the value proposition, product life models, current solutions, and the Verigo solution. Download Now!

Perishable Supply Chains Pod Quality Auditing Guide

This auditing guide details the perishable supply chains for growers, distributors, and retailers, and how using Pod Quality as an auditing tool makes complex supply chains less daunting to analyze with unprecedented insight and control. Download Now!

More Verigo: Resources

Article Topics

Verigo News & Resources

Walmart’s Eden and Verigo’s Pod Quality: Technology to Reduce Fresh Produce Waste in Supply Chains An Inconvenient Truth About the Produce Supply Chain - Is New Tech The Solution? Bringing the Internet of Things to Fresh Food Cold Chain Logistics & Supply Chain Management Pod Quality: Continuous Product Life Data From Farm to Store Let’s Build a Smarter Food System Perishable Supply Chains Pod Quality Auditing GuideLatest in Supply Chain

TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Nissan Channels Tesla With Its Latest Manufacturing Process Taking Stock of Today’s Robotics Market and What the Future Holds U.S. Manufacturing Gains Momentum After Another Strong Month More Supply Chain