Supply Chain Media and partners launch new strategy assessment tool

Supply Chain Media and partners launch new strategy assessment tool

Supply Chain Media, Districon, DSV and Nyenrode Business University have developed a new strategy assessment tool: Supply Chain Satellite. A group of logistics professionals and academics have combined their specialist experience from various aspects of the logistics outsourcing process to develop a framework for logistics outsourcing. The tool consists of a detailed questionnaire, a sophisticated scoring model and an in-depth analysis covering all possible logistics outsourcing strategies.

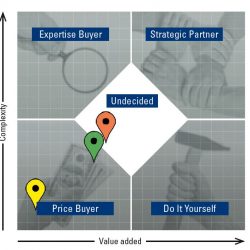

Based on your answers you will be provided with an analysis of your current situation and the bestin- class strategy towards outsourcing logistics activities. Your answers will be scored, weighted and subsequently plotted into the Outsourcing Strategy Assessment model. The model consists of 2 axes that form the basis of your position:

X. Added value of your supply chain

This axis measures to what extent your supply chain and specifically your logistics process adds value to your product. It determines whether, and to what extent, differentiation of your logistics processes can impact your competitive position. Indirectly this axis also measures the impact of logistics on your bottom line since a differentiated logistics model will justify higher margins.

Y. Complexity of your supply chain

This axis forms the unit of measure for the complexity of your logistics operation. It measures how easy it is to standardize your logistics processes. It is a fundamental factor that highly influences the type of relationship you will have with a Logistics Service Provider.

4 archetypes for logistics outsourcing strategy

1. Price Buyer

Cost containment in the logistics chain is your main objective. You have limited or no need for highly specialized logistics competences of the 3PL. This makes it easy for you to select a provider. You make sure you know the cost leaders among the Logistics Service Providers and develop relations with them in each geographical market. Minimising the logistics cost as part of the final selling price of your product represents an important source of competitive advantage. It can lower the price for which you can offer your product to the end user or alternatively improve your margin. The logistics operation should contribute to these objectives but does not, in itself, impact the perceived value of your products.

2. Do it Yourself

You do not outsource or hardly outsource any logistics activities and have no need to develop relations with Logistics Service Providers. Because of your highly customized handling and shipping requirements you have custom built these capabilities yourself. Other reasons for your situation could be that you are locked into an insourced logistics operation. Re-organisation costs in terms of job loss facilities would outweigh potential benefits of outsourcing. Alternatively you could have had previous negative experiences with Logistics Service Providers or you are sceptical about the true cost of outsourcing.

3. Expertise Buyer

Your logistic activities are complex and you have a wide portfolio of products, suppliers and customers. Product life cycles are short and you face critical time-to-market requirements in a volatile market. Logistics outsourcing in principle should be a longterm commitment to the Logistics Service Provider as this allows you to capitalize on continuous improvement and cost reduction. Logistics Service Providers are selected on specialist expertise, technologies and assets and will be deployed in those parts of the Supply Chain where they bring substantial benefit.

4. Strategic Partner

Your logistic activities are complex and of high strategic importance. You have a wide portfolio of products, suppliers and customers. Product life cycles are short and you face critical time-to-market requirements in a volatile market. Your contracts with Logistics Service Providers are aimed to facilitate long-term commitment. Together with your Logistics Service Providers you work on a program of continuous improvements in; service levels, flexible delivery options, lead times, warehouse efficiency and eventually cost reduction.

Undecided

There is no or almost no conscious strategic approach. You either take conflicting approaches regarding the management of your logistics operations or you lack a clear approach. There can be many possible reasons for this lack of strategic direction. In a positive scenario you find yourself in a transitional period where a strategy is defined but far from implemented. Conflicting views within the Supply Chain function or in your company’s strategic management can also cause logistics processes and improvement projects to even each other out and result in a status-quo.

Want to read more about sterategies? This report tells you all about it!