In today’s world, most commerce depends on an international supply chain one way or another. Whether it’s contracting the manufacture of goods or simply ordering parts from another country, few products are sold that are totally made in the USA, creating a vulnerability to international Supply Chain disruptions.

Unfortunately, even a slight disruption in the supply chain could put your company at a huge disadvantage which could, in turn, significantly impact your bottom line. If you work with suppliers in various foreign countries, you’ll want to avoid disruptions at all costs.

1. Recognize the Importance of Accurate Communications

In the realm of manufacturing, communications can be a major setback. Consider for just a moment trying to communicate with someone in China who speaks very little English yet had the lowest and most cost-effective bid on the parts they will manufacture.

Accurate technical translations are essential for those working in an industrial/manufacturing role because there are times when you require a modification. Instead of going back and forth with prototypes, it might be best to hire a technical translation team to get it right the first time.

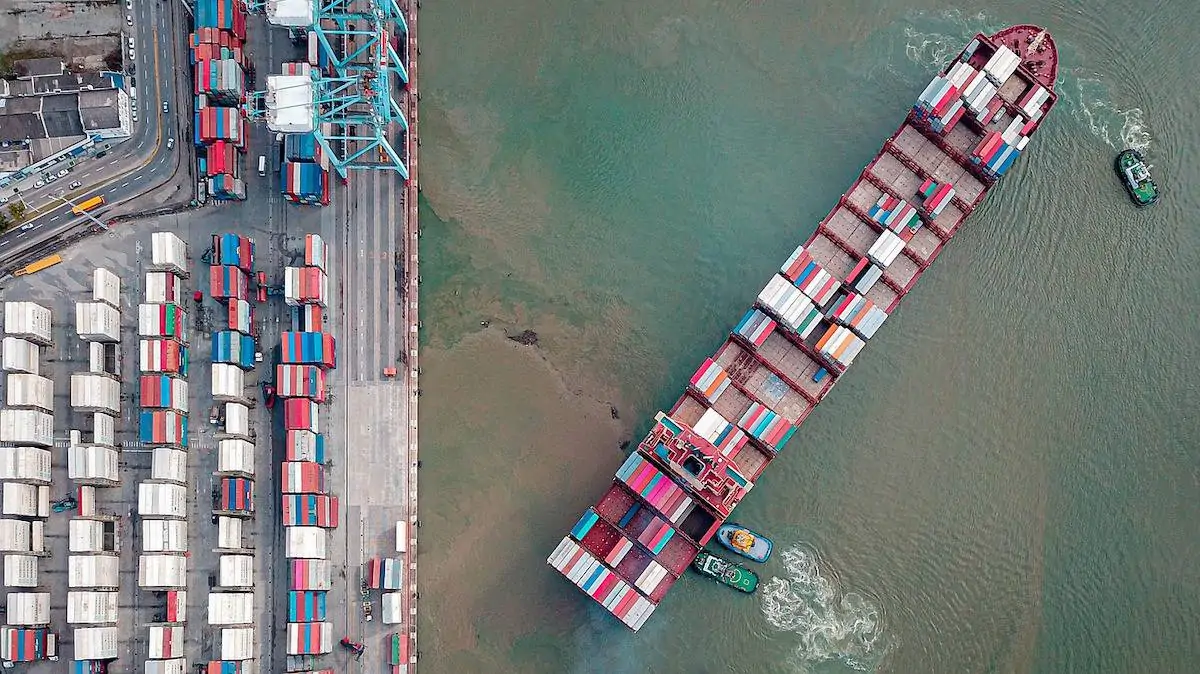

2. Be Prepared for Backup Transport

Another major issue is often brought about by the inability of your usual mode of transportation to move products timely. Whether they are dealing with a backlog of work or are suffering due to such things as natural disasters, their lack of availability could put a huge delay in your supply chain.

It is always wise to have back up transport companies on the line in case the need arises. These alternative modes of transport may not normally be as cost-effective, but they will certainly help you avoid taking a loss.

3. Stockpile the Most In-demand Inventory

Supply and demand are as much an art as a science. There are times when your market explodes and the length of time it would take to order more products or parts would send your clients elsewhere. Since predicting the market isn’t always as accurate as you’d like, it’s a good idea to keep a stockpile of your most in-demand inventory on hand.

However, here a word of caution is in order. Since there is no way to predict a future market, don’t go overboard. Perhaps keep a stockpile that would see you through the length of time it would take to order another shipment. It’s good to be prepared but not wise to overdo it.

Remember, although we live and work in a global society where much commerce and communication take place in cyberspace, physical items need to be moved from one location to the next. If you are working with companies in foreign countries, be cognizant of the fact that there may be language barriers to deal with as well as disruptions in the transport of products.

Ensure that all communications are accurate while keeping alternate modes of transportation and suppliers on line. Sometimes that extra inventory you’ve stockpiled will meet your needs, but you can’t always depend on that either. Try to plan for any eventuality that could disrupt the chain and your business will stay on an even keel.