Supply Chain Preparedness Lessons Learned: The Gulf Coast Refineries and the Texas Storm

I interviewed some individuals who work in the Houston area and learned more about what happened. One supply chain executive shared with me some of the challenges they experienced during the Texas Winter Storm that hit last week.

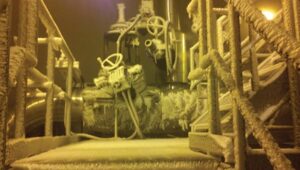

“It was hell. All of the incoming gases that came through pipelines were being “force majeured”, (a contractual term that reflects to disruption of supply due to an act of God.). This essentially shut down production for all of the petrochemical plant. Freezing and ice were the major issues. I watched as 2.5’ pump valves exploded or cracked because of icing – the valve literally split apart before my eyes! To watch it happen, and then to see pictures of valves or flanges cracking – there is nothing like that. People on the Gulf Coast are not used to those temperatures, and it resulted in several days of shut downs. The snow came in Sunday night, but did not melt until the following Saturday. We did not have temperatures above freezing until Thursday. Roads were in terrible shape, and everything was shut down. Electricity was hit or miss, and people could not even get food from stores.”

Supply chains at that time were being operated by cell phones, since power was down, and computers could not be charged. But everybody was up and running, and companies handed out emergency supplies, including bottled water, from warehouses.

Some of the biggest problems involved shipments of nitrogen and hydrogen – as all the pipes had large cracks and leaks. These are under repair. There was also a shortage of trucks to get materials into plants. One of the biggest providers of gases, Air Liquide, was really hammered. They handle a majority of the gases on the Gulf Coast, and were struggling. As a result, there has been a 5 to 10-day backlog due to the shutdown. Most plants were down from anywhere from 2 to 7 days, and some even 10. They also couldn’t get workers in, and the backlog of raw materials combined to make it one of the worst storms ever to hit the Gulf Coast refineries.

Some plants were affected less than others, due to advance preparation. Those that were exclusively dependent on nitrogen coming in by pipeline had it the worst. Some had nitrogen trucked in by Air Liquide, and kept a reserve on hand that was enough to keep them up and running. Some organizations had a risk playbook in play, as recommended in our recent HBR article on business preparedness. But everyone knows that, even with a weeks’ warning of the incoming storm, even the best-laid plans can be shattered due to freezing. There are always lessons learned from such events, that emphasize the need to be better prepared for the unknown.

It’s probably not the last winter storm we’ll see in Texas, just like it’s not likely the last coronavirus that comes back as well. Supply chain preparedness is a critical part of how your business needs to plan for the future.