Supply Chain Performance Declined In the Last Decade. The Question is Why?

Supply Chain Shaman

APRIL 9, 2021

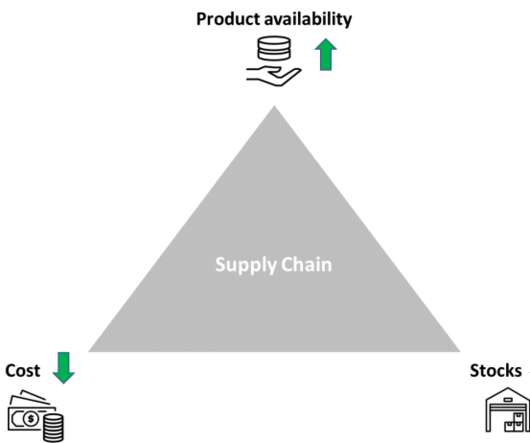

Rise in Inventories. Less Effective at Inventory Management. Inventories grew twenty days over the decade. Yes, companies held more inventory (measured in days of inventory) in 2019 than at the start of the 2007 recession. Sadly, most of it is the wrong inventory. Belief in efficient procurement.

Let's personalize your content