Supply Chain Performance Declined In the Last Decade. The Question is Why?

Supply Chain Shaman

APRIL 9, 2021

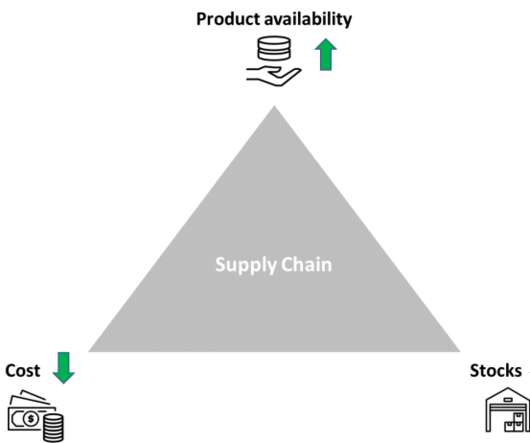

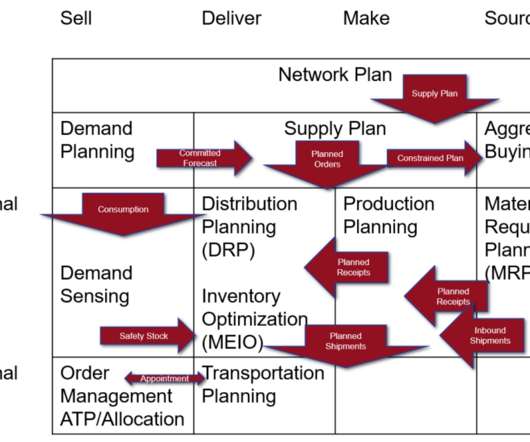

Yes, companies held more inventory (measured in days of inventory) in 2019 than at the start of the 2007 recession. Commercial and operating teams in manufacturing organizations greater than 5B$ in annual revenue were more aligned in 2007, at the beginning of the recession, than in 2020, the start of the pandemic. Alignment Barriers.

Let's personalize your content