Lifting The Gray Curtain

Supply Chain Shaman

SEPTEMBER 22, 2021

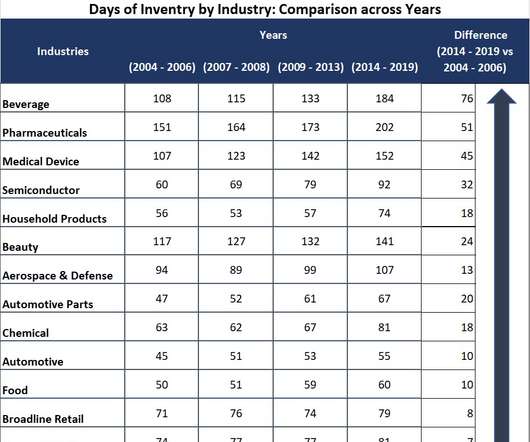

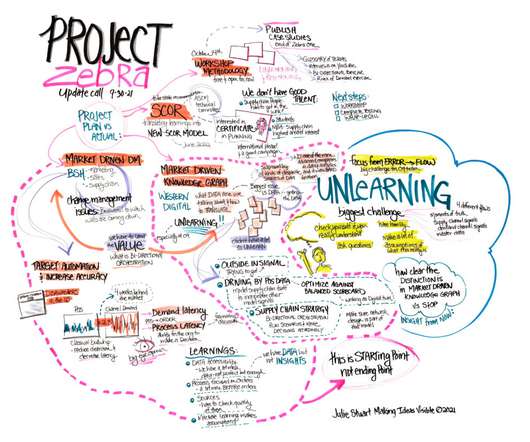

In our research, we find that 72% of planners primarily depend on Excel and desktop analysis despite the rollout of advanced platforms for planning in 92% of manufacturers with greater than 5B$ in revenue. We started the pandemic with twenty-one more days of inventory than we had in 2007. The question is, “Why?”

Let's personalize your content