Have You Given Your Planner Love Today?

Supply Chain Shaman

FEBRUARY 11, 2019

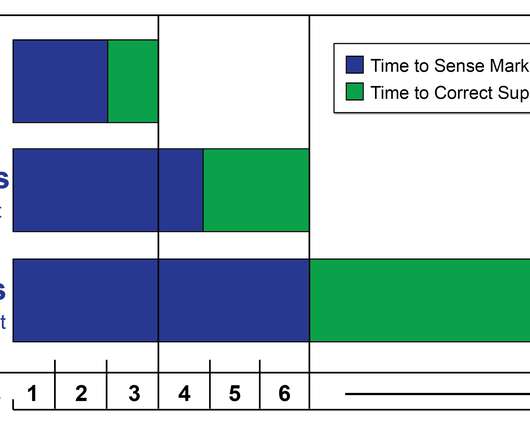

In Figure 1, note the lowest satisfaction is Generation X (birth years of 1965-1980) in manufacturing organizations. It took six months for supply chain executives to sense the market downturn of 2007 and make adjustments to their supply chain. In my share groups, large manufacturing clients have a Q1 freeze on travel.

Let's personalize your content