My Vision for Supply Chain 2020? Deep Integration!

Arkieva

APRIL 1, 2016

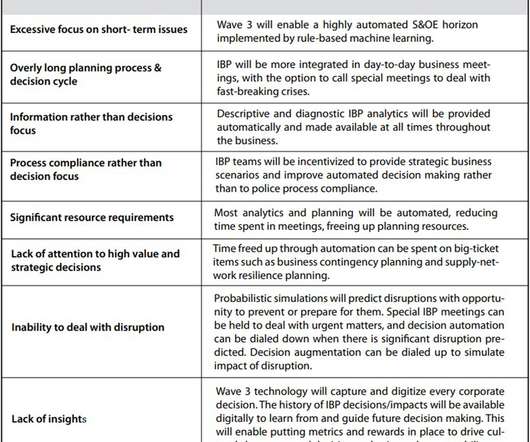

The question was how I imagine the Supply Chain in 2020. The financial crisis of 2008-2009 has given a major push to do more with less. Excess capacities in one region are dumped in another region and are disrupting market shares. This will ensure we keep moving to the next level as we’re marching to 2020.

Let's personalize your content