As supply chain professionals and SCM technology enthusiasts, our conversations and discussions are often forward-looking. Sometimes, it’s essential to focus on the here and now, before looking ahead. In this post, we’ll cover some of the basics of what supply chain management entails, and why it’s a critical component in fueling supply chain innovations.

Outside of working on math problems and playing basketball or soccer, my favorite activity is to attend the live theatre of all kinds. I recently came across the Fantasticks – the song “try to remember” reminded me it is “time to remember” the core of supply chain planning as we investigate the role of artificial intelligence (AI) on this area.

Organizations, from healthcare facilities to manufacturing giants to small restaurants, can be viewed as an ongoing sequence of loosely coupled activities where current and future assets are matched with current and future demand across the supply chain or demand-supply network.

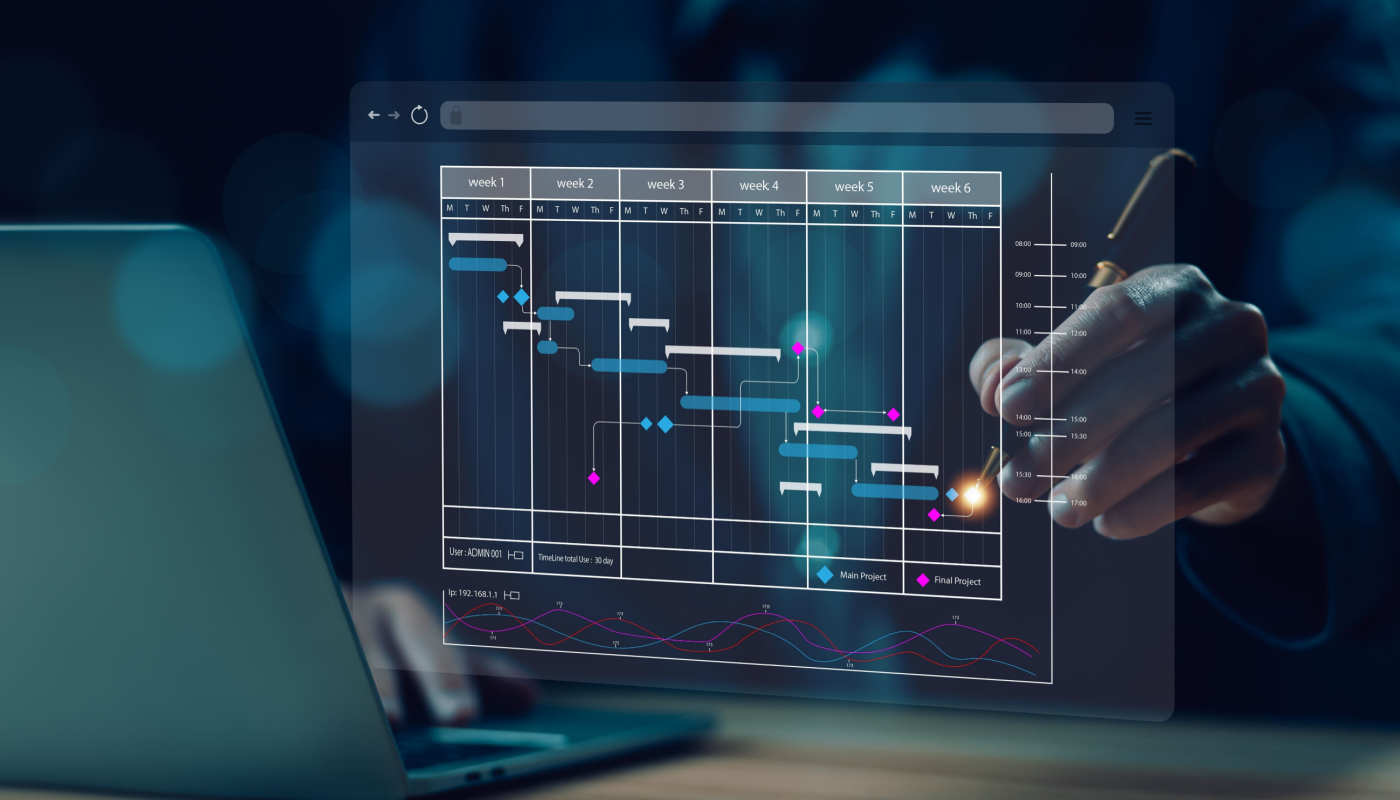

These planning and scheduling decisions occur across a complex playing field organized by decision tier (strategic, tactical, operational, and relevant time response) and organization (corporate planning, factory, marketing, purchasing, etc.).

The purpose of Supply Chain Management (SCM) is to keep chaos at bay – synchronizing the activities of the network. All SCM or central planning processes created to manage an organization’s demand/supply network consists of three primary activities, as well as two secondary activities.

Primary Activities of Supply Chain Management

The three primary activities of supply chain management include:

- Demand Management – Understanding the exit demand, quantity, due date, certainty and priority of an organization’s products. To achieve successful demand management, it is key to have current data, collaboration and a wide range of visibility. Best-in-class demand software solutions help organizations achieve these requirements by providing seamless access as needed to key data like ship history, order history, forecast history, and current forecast. As well as, the ability to dynamically aggregate and disaggregate the data, implement various forecasting methods, and create a collaborative environment. Through effective demand management, an organization can automate the routine aspects of their process, quickly analyze emerging opportunities, and focus on understanding their market to improve responsiveness as opposed to the mechanics of creating the demand estimate.

- Supply Planning or Matching Assets with Demand – Balances or matches assets such as inventory, resource capacity, and production routes with demand to determine what can be met and how different asset levels impact the projected supply plan linked to demand. The methods deployed differ based on the level of granularity, the inherent nature of the industry, and the algorithm(s) used to match or balance assets with demand. It is important to determine which method is best for each specific situation. Other names associated with this process are master planning, central planning, rough cut capacity planning, and replenishment planning. However, in all cases, there are two main goals: insight for responsiveness and synchronization.

- Analytics Workbench – Using analytics to create insights that can help determine the exchange between those involved in the SCP or S&OP process. Generating the demand statement and executing the matching process are just the start of the supply chain planning process. The real work is the analysis of the source data and model results to ensure the organization is not overcommitted, and more importantly, those opportunities are not missed. This is sometimes referred to as the “repair” process. Key elements of support are basic business analytics and dynamic, or pro-active, analytics.

Secondary Activities of Supply Chain Management

The two secondary activities of SCM are:

- Available to Promise (ATP) – ATP Focuses on specific commitments to make to customers when an actual order is placed. “Complexity” can range from simply looking at available inventory to complex trade-offs with projected inventory to altering the relative importance of tasks for execution.

- Inventory Modeling and Policy – This activity is based on understanding what inventory levels occur simply as a result of the nature of your network, as well as, locating safety stock to buffer against the inevitable variability in demand and supply. The purpose of setting inventory policies is to manage risk. Inventory models help management understand the risk.

ATP and inventory modeling and policy setting are considered secondary activities of supply chain management because the primary activities of demand, supply and analytics management must exist first.

[Read More: 5 Things to Know About Setting Up a Better Supply Chain Performance Measurement System]Starting or Improving Planning with Supply Chain Management Software

Organizations that are just starting the journey of using software to support more intelligent SCP will often, but not always start with demand management followed by either an aggregate level supply planning application or an inventory model. After these are in place, typically an assessment is made to determine the next steps that best benefit the organization. It has been proven that following an incremental process for enhancing existing or implementing new functions is the best practice. An organization already into the journey should begin with the assessment. However, the critical concept to remember overall integrated areas is this is a “plan,” not the execution.

Benefits of having an SCM improvement plan are:

- You create expectations for an organization that are feasible but do not leave opportunities on the table.

- You ensure the “assets” needed are in place.

- You synchronize the overall activities of the organization.

Last, having this process in place with depth, breadth, and flexibility enhances the value of business knowledge and intuition, not replace it and creates the necessary base to bring AI methods to bear on key challenges.

Enjoyed this post? Subscribe or follow Arkieva on Linkedin, Twitter, and Facebook for blog updates.