Transportation Metrics That Matter Most to Track and Improve Performance

GlobalTranz

JULY 1, 2021

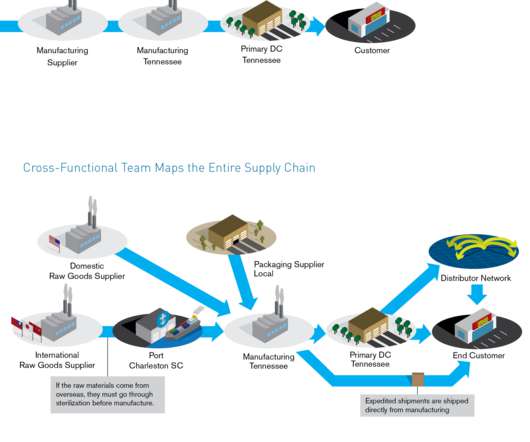

Creating a data-driven supply chain tracking important transportation metrics helps shippers respond and adapt as quickly as possible to known and unknown events. Why Monitor Transportation Metrics. Transportation metrics provide visibility that helps drive operative and competitive advantages.

Let's personalize your content