2020: Manufacturing, a Year in Review

QAD

JANUARY 21, 2021

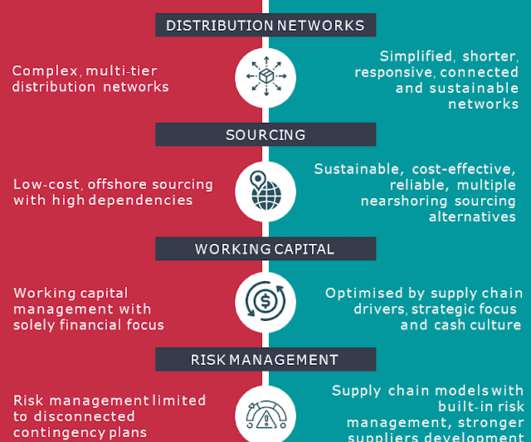

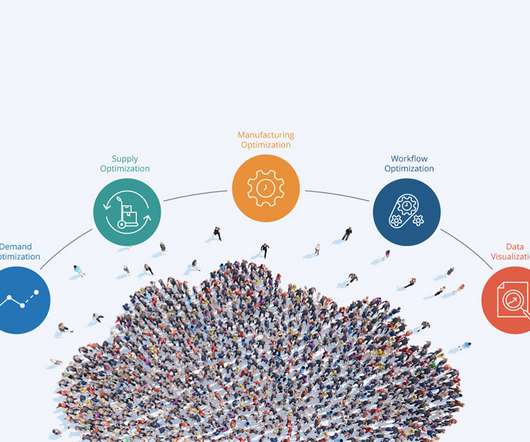

If global manufacturers learned anything from 2020 it was that disruption is the new normal. To take the Adaptive Manufacturing Enterprise Maturity Model Diagnostic go to: www.qad.com/adaptive-manufacturing-enterprise/diagnostic. The post 2020: Manufacturing, a Year in Review appeared first on QAD Blog.

Let's personalize your content