As we head into 2024, it’s important to remember (and apply!) the important lessons learned from the past few years, especially those in response to the Covid pandemic.

One of the key lessons learned is the importance of creating a resilient supply chain.

As the authors of a July 2021 Boston Consulting Group article state, “Greater efficiency [comes] at the expense of diminished flexibility and effectiveness — a tradeoff the pandemic-induced supply chain disruptions have made painfully clear.”

Therefore, it is now important for companies to balance cost and efficiency with supply chain resilience — defined as “the ability of a supply chain to both resist disruptions and recover operational capability after disruptions occur.”

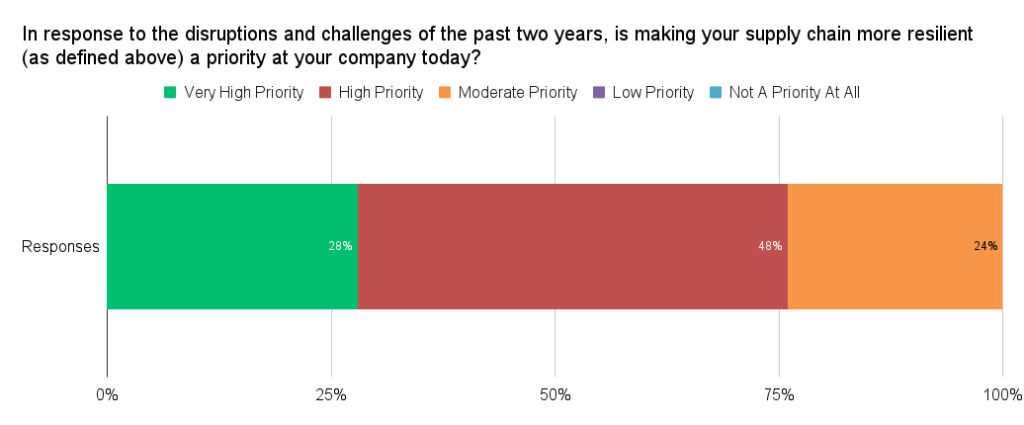

In an April 2022 survey conducted with members of our Indago supply chain research community — who are all supply chain and logistics executives from manufacturing, retail, and distribution companies — more than three quarters of the respondents (76%) said that making their supply chains more resilient had become either a “Very High Priority” (28%) or “High Priority” (48%).

Source: Indago, April 2022 survey (n=26)

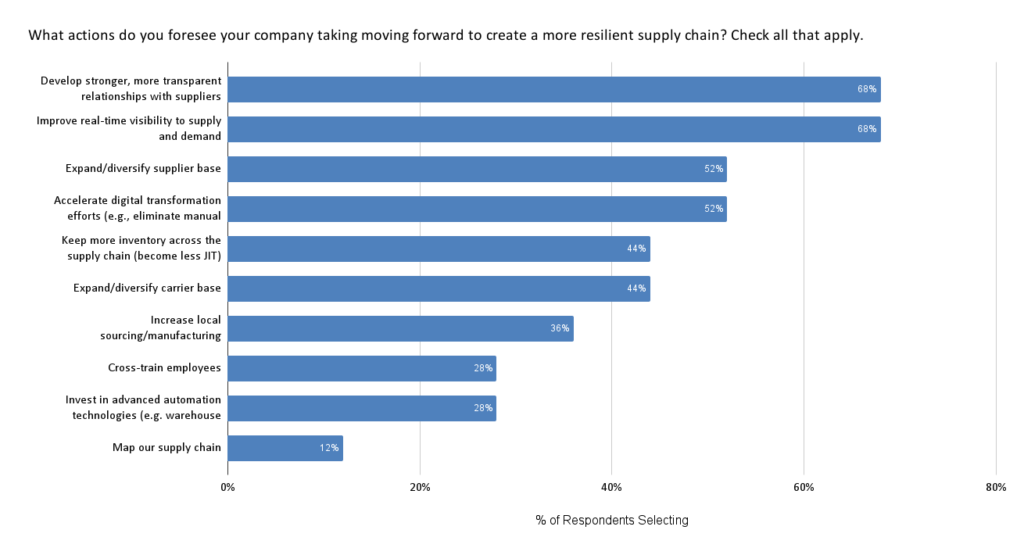

And in terms of the actions they planned to take to make their supply chains more resilient, “Develop stronger, more transparent relationships with suppliers” and “Improve real-time visibility to supply and demand” topped the list with 68% of the respondents selecting those actions.

Source: Indago, April 2022 survey (n=26)

Another important lesson learned is that collaboration is no longer an option; it is imperative to effectively address the supply chain and logistics challenges and opportunities of today and tomorrow.

In an October 2022 Indago survey, for example, almost all the respondents either “Strongly Agreed” (71%) or “Agreed” (25%) that for companies to address the supply chain challenges they face more effectively moving forward, they will have to collaborate more with their suppliers, customers, logistics service providers, and other trading partners.

Source: Indago, October 2022 survey (n=24)

It is also now clear that sustainability is moving from being something companies do voluntarily to something that is becoming mandatory. In April 2023, for example, the European Union Parliament approved a carbon import tax, and in September 2023, California passed a carbon emissions mandate that will require companies with over $1 billion in revenues that do business in the state to disclose all greenhouse-gas emissions associated with their operations, including Scope 3 emissions.

In a November 2023 Indago survey about this California law, most of the respondents (59%) said that it will be “Extremely Difficult” (14%) or “Very Difficult” (45%) to comply with this new law. More than three quarters of the respondents (77%) said that “Obtaining emissions data from external partners (Scope 3)” will be the top challenge in calculating and reporting supply chain greenhouse-gas emissions.

When you take all these things into consideration — the need to develop stronger, more transparent relationships with suppliers; improve real-time visibility to supply and demand; communicate and collaborate more effectively with suppliers, customers, logistics service providers, and other trading partners; and obtain greenhouse gas emissions data from external trading partners — what is the best way forward to enable these capabilities?

Obviously, supply chain and logistics software applications, such as Supply Chain Planning, Procurement, Transportation Management, Warehouse Management, and Visibility, will play important roles. But software alone is not enough. Companies also need an efficient and scalable way to communicate and collaborate with external trading partners because so much of what happens in supply chain and logistics happens outside the four walls of the enterprise.

This is where Supply Chain Operating Networks — aka Business Networks — come in.

Business Networks Transcend Functional Silos

Business Networks are the business equivalents of Facebook and LinkedIn. Instead of companies creating hundreds or thousands of one-to-one connections with their trading partners, they make a single connection to the business network, where their trading partners and thousands of other companies are also connected, and they use the cloud applications that reside on the network to communicate, collaborate, and execute business processes in more efficient, scalable, and innovative ways.

Business Networks also provide companies with a more holistic and integrated view of their supply chain. That is, they help companies see how their various functional and process silos are linked (such as Procure-to-Pay, Order-to-Cash, and Integrated Business Planning), and they help break down these silos by facilitating the flow of data/information and the execution of workflows across these processes.

In short, Business Networks enable companies to take a more modern, end-to-end supply chain centric approach to “Staple Yourself to an Order,” which is what Benson P. Shapiro, V. Kasturi Rangan, and John Sviokla recommended in their 1992 Harvard Business review article. As they wrote at the time:

Managers who “staple themselves to an order” will not only move horizontally across their own organization, charting gaps and building information bridges, but will also see the company from the customer’s perspective. There’s no better way to alter that perspective, improve interdepartmental relations, and—over the long haul—improve financial performance.

To paraphrase the quote above, Business Networks enable companies to chart gaps across their end-to-end supply chains; build information/data exchange bridges between internal functional groups and external trading partners; and improve relations with suppliers, customers, and other partners. That is, they help companies implement the lessons learned discussed earlier.

Roca Group: Bringing Together Supply Chain and Logistics Collaboration with Business Networks

“We need to think in ecosystems,” said Jacques Niewland, Corporate Director of Digital Transformation and IT at Roca Group, during his presentation at Spend Connect Live in October 2023.

This comment caught my attention because it echoed what I wrote in January 2016 in “Here Comes The Chief Network Effects Officer”:

I believe the time has come for companies to view supply chain management through a ‘network effects’ prism, and when you do that, we’ll see today’s supply chain leaders and teams morph into tomorrow’s Chief Network Effects Officers and Network Effects teams.

Niewland was talking about how to drive operational excellence across Roca Group by digitizing their core processes. “We have a lot of back office tasks. How can we automate them? How can we eliminate non-value-added tasks, for example, between customers and us or between suppliers and us? How can we improve collaboration across the supply chain? To do that, we need to look at skills, we need to have good data to gain insights from, and we need to think in ecosystems.”

As a €2 billion bathroom solutions company, with 84 factories in 22 countries and serving 170 markets, Roca Group’s supply chain is certainly global and complex. “In the supply chain, the objective is always to optimize service to customers and cost to serve, and we need to balance those two dimensions [in an ideal way],” said Niewland. “To do that, we need great collaboration within the value chain, we need to destroy these [process/functional] silos, and we need to collaborate well with our partners. That means having real-time transparency, a single source of truth, where everyone has the same information at the same time.”

Niewland added, “Supply chain is always a network with our customers, warehouses, plants, and suppliers. We are trying to optimize the information flow [across our network] by using several SAP solutions, including SAP Business Network for Supply Chain Collaboration and SAP Business Network for Logistics Collaboration.” (SAP is a Talking Logistics sponsor).

On the supply chain collaboration side, for example, Roca Group is leveraging the network for “Integrated Business Planning to get accurate demand from the sales departments, to check it with capacity, check it with the factories, check it with supply to see if we can make this plan happen and achieve very high levels of service,” explained Niewland. They’re also using the network to collaborate with suppliers on purchase orders (e.g., send/confirm receipt of POs, confirm or make adjustments to order quantities, provide order status updates, etc.).

“We are now at a run rate of €100 million PO volume on the Supply Chain Collaboration network, which is well over 100,000 order lines,” said Niewland. “We plan to grow it to a volume of approximately €400 million and double the order lines.”

On the logistics collaboration side, the network is integrated with Roca Group’s transportation management system (TMS). “The TMS optimizes pallets, truckloads, and routes and we exchange this info [via the network] with our forwarders and get feedback from them,” explained Niewland. The network also facilitates dock appointment scheduling, invoice verification, and provides visibility to final delivery to customers, something they lacked in the past.

Sustainability is one of Roca Group’s strategic pillars, along with operational excellence and digital transformation. This is another area where the company sees an important role for business networks. “We are using different tools to measure Scope 1, Scope 2, and Scope 3 emissions,” said Niewland. “And Scope 3 is extremely relevant. Our vision is that every transaction, be it transportation or purchasing, is accompanied by [greenhouse gas emissions] data. We are not there yet, but that is where we want to go.”

Niewland added, “In the future we want to activate SAP’s green ledger. At the moment we are estimating Scope 3 emissions, but [ultimately] we want to connect suppliers and have them report their emissions data directly on purchased materials.”

Like other companies using business networks, Roca Group started with one collaboration scenario first and then added more over time. “The big thing we want to do next is to integrate Planning, Transportation Management, and Purchasing,” said Niewland. Simply put, the next wave of innovation, process automation, and business benefits will come when the remaining silos are removed to enable true end-to-end supply chain collaboration.

The Bottom Line

Roca Group’s case study illustrates how business networks are helping companies to:

- Develop stronger, more transparent relationships with suppliers;

- Improve real-time visibility to supply and demand;

- Communicate and collaborate more effectively with suppliers, customers, logistics service providers, and other trading partners;

- Obtain greenhouse gas emissions data from external trading partners.

That is, business networks are helping companies to implement the lessons learned from the Covid pandemic in order to create more resilient supply chains and position themselves for success moving forward.