How to Build a Future-Ready Supply Chain: A Strategic Roadmap for 2023

The past few years have taught us a lesson or two in the importance of prepping conventional supply chains to face disruptions of any kind and magnitude. From empty store shelves to vanishing essential commodities, especially when demand for these peaked wasn’t an easy pill to swallow. Supply chain planners and leaders have been on a roller coaster ride ever since and haven’t been able to overcome the impact just yet.

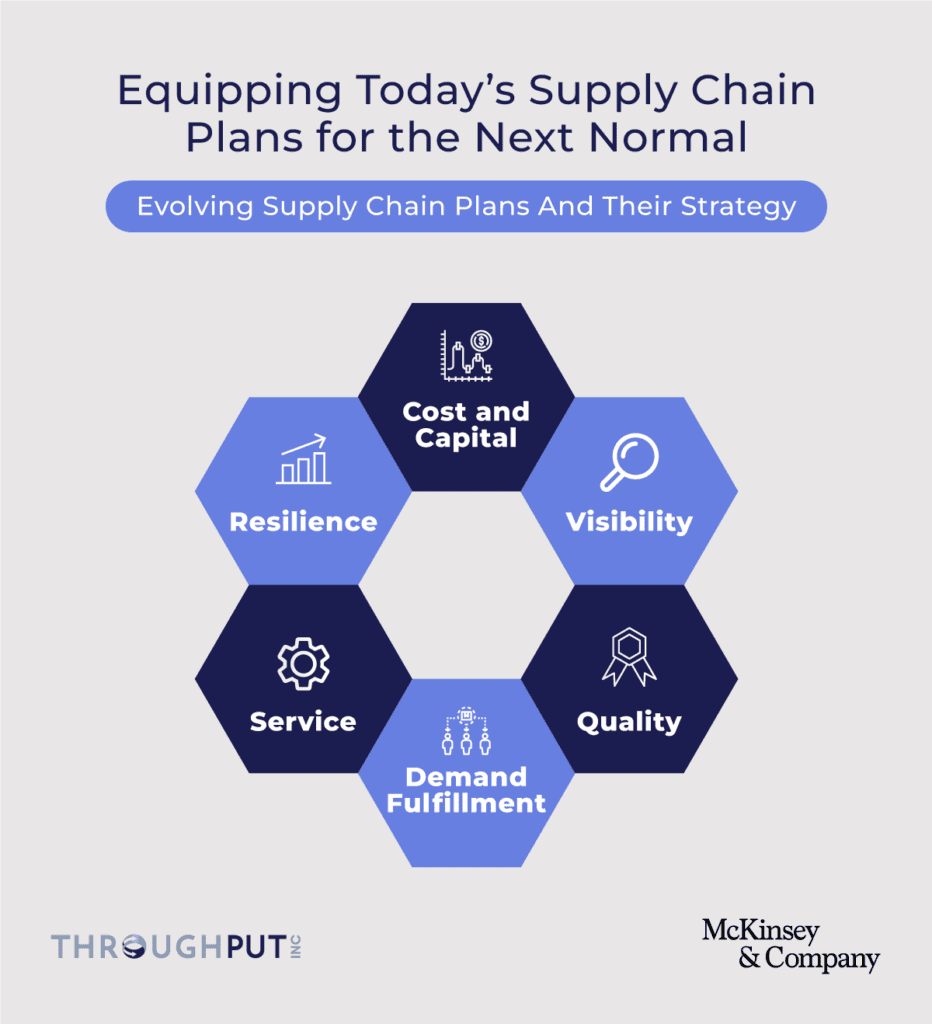

According to McKinsey, the next normal supply chains will look extremely different, will be multifaceted and more complex from the ones we have seen so far. The strategy for supply chain planning, therefore, has to be equally aligned and accurate to respond to the plethora of disruptions that this next normal will bring with it.

Forward-thinking Chief Supply Chain Officers (CSCOs) are seeing the current scenario as a once-in-a-decade opportunity to future-proof their supply chains; just to ensure that the aftermath of another calamity does not take them a few years back and offset their profits to recuperate from irreparable losses.

Among the several ways “future-proofing” can happen, the three most important priorities are the ability to drive Enterprise-level Visibility, create adequate Resilience and also ensure Demand Fulfillment at all times for financial viability.

- Make enterprise-wide visibility a driver for your plans – With AI-driven enterprise-wide visibility, CSCOs get an end-to-end yet granular view of their supply chains, thus, helping weed out deep-rooted operational inefficiencies. With this level of visibility, it becomes easy to unclog bottlenecks and fix issues before they grow into larger problems that hamper productivity. This, in turn, helps improve both quality and productivity while at the same time enabling the detection of opportunities to reduce cost and resource utilization.

- Ensure accurate demand fulfillment to tackle market fluctuations – Secondly, by ensuring demand fulfillment at all times with AI-powered demand sensing and forecasting capabilities, there is no possibility of under or overproducing again. The ability of AI systems to analyze and decipher massive datasets rapidly and at scale ensures highly accurate demand forecasts. This enables highly precise capacity planning, tailored to meet demand every time. With intelligent algorithms that identify and predict new demand patterns by way of shifting consumer habits, changing seasons, etc., adapting to changing demand patterns becomes easy, and as a result, businesses become more resilient in the face of changing market conditions.

- Ensure a strong and resilient supply chain to prepare for future uncertainties – Supply chain resiliency is a necessity for today’s evolving supply chains as it shows the ability to respond immediately to operational disruptions. When a supply chain is resilient and agile, it is able to use flexible contingency planning and forecasting – from material procurement to logistics and to the final delivery of products and services.

According to Geraint John, VP Analyst at Gartner

“Most supply chain leaders recognize that becoming more resilient is a necessity in the current environment,”

The key here is to rebalance efficiency and resilience as most of the time increased resilience comes with additional costs. But CSCOs need to compare the actual cost of doing nothing versus investing in future-proofing the supply chain.

Anticipate, Automate, Collaborate: Effective Supply Chain Strategy for 2023

The most resilient, responsive and agile supply chains are those which are equipped with resources and expertise to enable them to perform consistently, and move away from resisting and recovering. The supply chain plans of tomorrow are empowered with powerful AI-driven analytics which help CSCOs forecast, plan, act and respond quickly to whatever risks or uncertainties that may show up.

In fact, a strong and resilient supply chain planning mechanism can help supply chain leaders with the much-needed tools to recuperate and progress. Research shows that 79% of organizations with high-performing supply chains achieve greater revenue growth compared to the industry average. Also, companies with optimal supply chains benefit with 15% lower supply chain costs, less than 50% of inventory holdings and 3x faster cash-to-cash cycles.

Here are the 3 actionable guidelines for CSCOs to accelerate Supply Chain Optimization and Planning over the next few years.

- Anticipate, assess and plan for risks before they occur- It is important for supply chain leaders to move away from reacting to issues after they occur to planning and pre-empting risks with rising material and labor shortages.

- Leverage process automation and modernisation – Use the right AI-driven technology to make use of digital transformation and ensure process automation to save costs and time.

- Enable cross-functional collaboration across the value chain- Innovation thrives with effective collaboration and not in isolation. Therefore, it is important to ensure real-time communication and action to further reduce operational delays across the supply chain processes.

Actionable First Steps Towards Holistic Supply Chain Planning

ThroughPut gives you the advantage of end-to-end supply chain visibility with actionable insights at the right time, to help pre-empt risks and overcome the impact of operational calamities in the most profitable and intuitive manner. ThroughPut uses AI-powered Supply Chain Intelligence to help you leverage the benefits of complete supply chain transformation and achieve supply chain excellence in a seamless manner.

Get in touch with us to explore ThroughPut’s AI-driven supply chain solution.