PREVIEW

Integrated Business Planning (IBP) has been a valuable business process since its incarnation as Sales & Operations Planning in the mid-1980s. The monthly cycle of S&OP meetings has been the forum in which a firm’s forecasts have been presented and reconciled across functional areas. Authors Niels van Hove and Hein Regeer explain that while planning and forecasting technologies have benefitted from significant innovations since then, today’s IBP seems unhinged from the day-to-day operations of the business. They call for a reinvention of traditional IBP that more fully integrates its governing meetings and reporting into operations, enabling faster decision making, better responsiveness to disruption, and liberation for planners to work on more strategic issues.

KEY POINTS

- Many IBP cycles around the world are based on a 20-year-old process definition supported by 20-year-old planning concepts. This traditional IBP is not set up for a fast-changing world, where speed of decision making confers a competitive advantage. New Wave 3 Technology can empower a more efficient and responsive planning process.

- We propose that IBP be segmented by decision type into execution, operational, planning, and strategy/culture. For the execution and operational decisions, modern planning technology can largely automate processes and decisions. For the longer-term decisions on planning and strategy, technology will augment the quality of human-centric decisions and nurture human-machine collaboration.

- IBP should be converted from a separate, sequential, monthly planning cycle to an integrated component of day-to-day business. This will be feasible as new technology enables more autonomous decision making, freeing the planner to focus more fully on designing policies and targets

TRADITIONAL IBP AND PLANNING TECHNOLOGY

If we look back over the history of supply-chain planning, we can properly say we are in the third wave of integrated supply-chain planning software (Van Hove, 2019).

- Wave 1, Enterprise Resource Planning (ERP), started in the 1980s with a focus on automating transactional business processes, but less so on planning.

- Wave 2, Advanced Planning Systems (APS), first adopted in the 1990s, facilitated a forward view of the business, integrated plans with other functions, and optimized supply-chain metrics such as forecast accuracy, inventory holdings, and customer service.

- Wave 3 systems, now gaining momentum, will provide intelligent automation that replaces the human planning process as well as cognitive automation that augments a planner’s decision making with predictions, insights, and recommendations.

Wave 3 systems will enable fully automated planning, decision making, and execution. By bringing together several technologies that have matured separately over the last decade, it is becoming a system of intelligence, seamlessly integrating the following capabilities:

- Integration and harmonization of data from internal and external sources, with transactional data self-cleansed and planning parameters self-maintained.

- Automation of descriptive, diagnostic, predictive, and prescriptive analytics, including self-selecting machine-learning models for a library of predefined problems.

- Smart process flow through a digital twin that can be configured to mimic any business user during forecasting, planning, decision making, and execution processes.

- Prescriptive analysis and recommendations that provide business users with advice on why, how, and when to act.

- Automatic decision making and writeback of actions to underlying systems of record.

- Digitization of every decision made, using an automated loop that learns from both human and machine decisions.

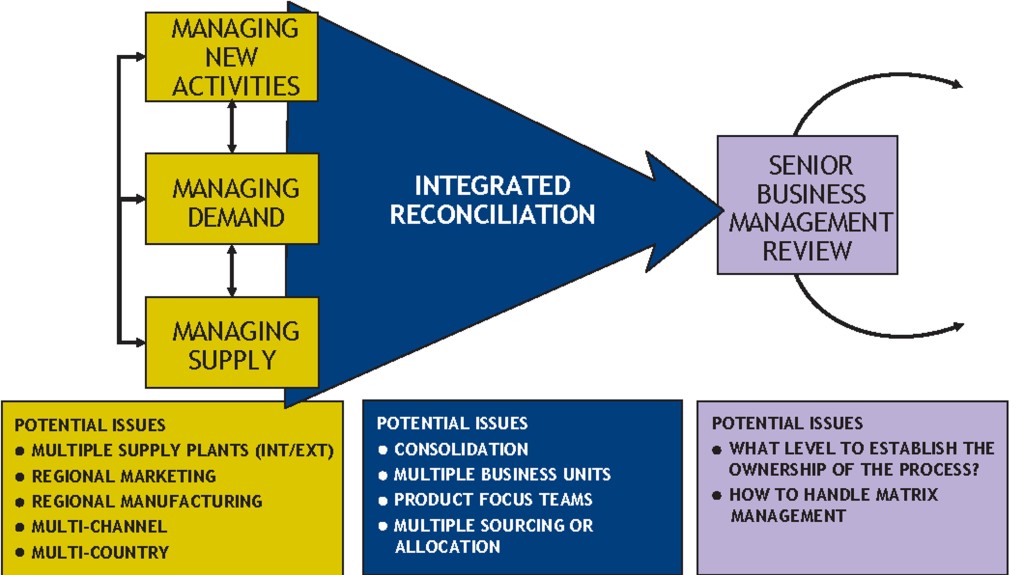

At about the same time that Wave 2 was gaining momentum, we saw publication of the book Enterprise Sales & Operations Planning: Synchronizing Demand, Supply and Resources for Peak Performance (Palmatier and Crum, 2002). The authors detailed a sequential S&OP cycle around a

New Product Review, a Demand Review, a Supply Review, and a Management Business Review. Figure 1 is an image from the cover of the book.

Figure 1. The IBP Cycle According to Palmatier and Crum

A whitepaper by Coldrick, Ling, and Turner (2003) entitled “Evolution of Sales & Operations Planning – From Production Planning to Integrated Decision Making” presented the five-step process – shown in Figure 2 – which is still the foundation of most planning processes today, even though the scope of S&OP has expanded into IBP.

Figure 2. The Five Key Steps of Integrated Business Management / Integrated Decision Making

In his 2009 Foresight article, Bob Stahl emphasizes the five-step sequential monthly process. Similar to the other publications, he asserts that executive S&OP is first and foremost a decision-making process.

The planning processes and governing S&OP meetings described in these publications have been widely implemented across the world, supported by Wave 1 and Wave 2 planning technology. These technologies focused on transactions, planning, and insights, but were never built for automated planning, decision making, and execution. Many of today’s IBP processes are still rooted in this prior generation of planning concepts, reflecting a notable absence of progress, especially considering that supply-chain executives expect to see autonomous supply chains by 2025 (Steinberg, 2019).

Autonomous supply chains, where decisions and actions will largely be made by machines rather than by humans, cannot be realized by Wave 1 and Wave 2 systems as these systems are aimed at automating processes rather than decisions. To become autonomous, supply chains require the new technology of Wave 3 planning systems, which we think of as systems of intelligence

LIMITATIONS OF TRADITIONAL IBP

As IBP managers, we have facilitated well over a hundred IBP meetings and, as consultants, we have implemented IBP processes across many countries and companies. We acknowledge the value of IBP in support of an organization’s effort to deploy and execute its strategy (Van Hove, 2016). However, we’ve seen the shortcomings of these processes as well, including reliance on old technology.

While IBP comes in many shapes and forms, it is based on a few foundational concepts.

- Cross-functional, human decision making. IBP seeks to align key stake[1]holders from multiple functions on “a single version of the truth”; that is, a common understanding of matters that need to be addressed and the collaboration needed in decision making.

- Periodic planning cycles. Most common is the weekly Sales & Operations Execution (S&OE) cycle to address immediate operational issues, and a monthly cycle for medium- to long[1]term issues. This dichotomy facilitates responsiveness in short-term planning while freeing senior management to focus on high-impact decisions over the longer-term horizon (and only by exception on operational issues).

- Sequential process steps. Both the weekly and monthly cycles follow a strict cadence of sequential meetings and activities. The outcome of one step (for example, the Demand Review) is required input for the next step (Supply Review). An IBP team typically drives the process and strives to maintain adherence to it within the organization. While these general concepts are straight[1]forward, implementation can be challenging. Even after decades of experience, companies struggle with persistent shortcomings:

- Excessive focus on short-term issues. Despite weekly S&OE meetings for operational issues, IBP meetings still become distracted by acute short-term issues. And even though the planning is designed to encompass a rolling 24-month horizon, IBP discussions are heavily skewed toward the first few months.

- Information and process focus, rather than decisions focus. Many IBP meetings take on an “information sharing” character rather than a decision-making focus. The meetings should mark the moments in the month where we “synchronize the watches” in terms of demand and supply plans. Because IBP managers are incentivized to adhere to the process – follow the agenda, attendance, data availability and standardized templates – the time spent policing process compliance steals from the time devoted to high-value decision making.

- Limited attention to high-value decision making. In a traditional IBP cycle, there may not be adequate time to prepare advanced simulations and business continuity plans, or to seek cross-functional alignment in time for executive-level decision making. One of the key reasons is the excessive number of meetings.

- Excessive meetings. Typical IBP cycles span a month’s time, but this can stretch to six weeks because of pre[1]meetings in which we prepare for meetings. Planners are now committed to prepare for the pre-meeting and then replan for the real meeting, all while trying to keep stakeholders aligned. It is not uncommon for an IBP meeting to take four to eight hours.

- Inability to deal with disruptions. In IBP cycles that span many weeks, executives cannot respond quickly to market disruptions. COVID exposed the inability of companies to make rapid strategic choices, such as in days or weeks – impactful decisions such as closing a factory, entering or exiting a product category, or reallocating limited resources in their supply chain. Some companies actively bypassed IBP by installing executive-led COVID war rooms to more rapidly implement strategic decisions.

- Lacking insights. Meeting notes and actions might be published after every IBP meeting; however, actions and outcomes are often not properly recorded, not measurable, or not easily accessible. This omission limits continuous learning and restricts the creation of corporate insights around decisions. Was the plan the right plan and the decision the right decision under

the circumstances? Was the right action taken by the properly authorized person? The authors believe these shortcomings can largely be addressed by aligning the IBP process with Wave 3 planning technology.

MACHINE-CENTRIC VS HUMAN-CENTRIC DECISION MAKING

While IBP has become nearly synonymous with “the S&OP monthly cycle,” there really is no compelling justification for this monthly frequency. By automating aspects of the process, Wave 3 technology can decouple decision making from this arbitrary cadence, allowing planners to concentrate more fully on goal setting and oversight of policies and systems, while providing the knowledge augmentation for these human-centric decisions.

Planning Horizons

This new technology will support decision making in different planning horizons. In earlier Foresight articles (Van Hove, 2020, 2021), Niels distinguishes decision automation from knowledge augmentation and examines the relative desirability of these features across different planning horizons. Longer planning horizons, for example, require human-centric decisions, while shorter-term operational decisions are more amenable to automation.

Figure 3 summarizes the possible enhancements to IBP from Wave 3 technology. The key is to segment IBP along decision type and then differentiate between machine-based IBP, which runs under highly automated planning and decision making with human involvement only by exception, and human-centric IBP, which will benefit from decision augmentation and human-machine collaboration.

Figure 3. IBP Segmentation by Planning Horizon, Automation, and Augmentation

Machine-Centric IBP Decisions

As shown in Figure 3, machine-centric decisions will be well suited for automation of both Sales & Operations Execution (S&OE) and Operational IBP.

In the short-term horizon (0-3 months), operational decisions are frequent, repetitive, low value, and granular (e.g. at the SKU/location level). These include demand and supply balancing, inventory change, order purchase and allocation, stock transfer, and product pricing. Such decisions require limited human alignment and sign-off. Hence, they can be automated to sense change or disruption in the supply chain and respond to it. Humans will still set policies and rules to structure the automated process.

Operational IBP decisions (4-12 months ahead) are less frequent and time urgent than in the S&OE horizon, but still have low impact/value and apply at a detailed level so that planning and decision making can be automated as well. Figure 3. IBP Segmentation by Planning Horizon, Automation

Demand-planning tasks, including data gathering and cleansing, statistical/ML forecasting, and detection of variances to targets and budgets, can be actioned automatically with only limited human-machine collaboration required. Human input will be required to set goals and policies to help the machine optimize promotions, price settings, and phasing of new-product introduction to reach certain targets. Supply-planning processes in this horizon can be partly automated. Due to the longer decision horizon and higher uncertainty, supply-planning decisions become more probabilistic in nature, and so will be amenable to medium levels of automation and augmentation.

Based on demand input, optimized supply plans can be automated to run concurrently across an entire network and pro – vide planning outputs for distribution, replenishment, and production. Even changes to planning parameters such as lead times, safety stocks, capacities, and batch quantities can be automatically updated, and gaps to service levels or cost structures in the supply chain will be detected and actioned automatically.

Many operational decisions that might look complex can be solved through business rules, machine learning, and probabilities. For example, when planning to introduce a new product to the market, the system can calculate a probability of hitting the introduction date and so automatically update the phase-out planning of the predecessor product.

For both machine-centric IBP segments, while many decisions can be automated, decisions above a certain value or probabilistic threshold will require crossfunctional collaboration and sign-off. Yet cross-functional meetings can become more agile by acting upon exceptions suggested by the machine.

Human-Centric IBP Decisions

Planning decisions in this category address higher levels of aggregation (e.g. product families) and normally have high impact/value. Since these decisions are more complex, they require human alignment and sign-off and so are less amenable to automation. The role of the machine is to support the planner in decision making, resulting in human-machine collaboration.

The machine can support the planner with probabilistic simulations and what-if scenarios, network or price optimization, multisourcing, new-product development, and innovation updates. It will detect gaps in revenue, margin, or cost versus targets and budgets automatically and provide recommendations for gaps closure. These recommendations will be actioned functionally for the most part, as pre-agreed policies and functional tradeoffs have been incorporated in the recommendation. In this way, IBP will morph into an aspect of business as usual rather than a distinct and dogmatic process.

At the strategic level, decisions are complex, infrequent, and high in granularity, as well as in value/impact on the business. They can also be cultural and value-based, requiring human alignment and sign-off at the executive level. These decisions are too complex and important to be automated, and they likely require human capabilities that the machine doesn’t possess. The human-centric nature of strategic IBP decisions means that a greater emphasis should be placed on governance – that is alignment, decision rights, rewards, and culture (Sorenson, 2020) – instead of automation.

Machines, however, can develop recommendations for executives around strategic scenarios, mergers and acquisitions, network risks assessments, geopolitical war games, category changes, onshoring versus offshoring, and large CAPEX in – vestments, thus providing probabilities and financial impacts.

A NEW SET OF IBP CONCEPTS AND ASSUMPTIONS

Segmented by decision type as is Figure 3 and supported by new Wave 3 technology, the new IBP will improve a firm’s ability to address many traditional IBP challenges and create structures that are far more aligned with current times. These are summarized in the table below:

To start the transition to this new type of IBP, we need to establish a fresh IBP mindset, supported by new aspirations and assumptions. We suggest replacing the foundational concepts discussed earlier by the following:

Data and Analytics

- IBP will automatically gather and cleanse relevant internal and external data and distribute these across the business in one common data layer, near real time. This will permit sales to change prices and demand forecasts up to a certain threshold (say 25%) w/o consulting finance or operations.

- It will automatically provide descriptive and diagnostic analytics and make these available at any time throughout the business.

Planning

- Planners will guide the machine with policies, goals, and targets.

- Planning will take place continuously and require human input only upon matters that exceed certain impact or complexity thresholds.

- The machine will identify variations and gaps to plan and automatically action these up to a defined threshold. Above that threshold it provides recommendations to be decided upon by humans.

Process & Meetings

- The frequency and duration of IBP meetings will be driven by decision requirements, not process requirements.

- IBP teams will be incentivized to provide strategic business scenarios and improve decision making, not to police process compliance.

Decisions & Execution

- IBP decisions and impacts will be recorded digitally, applied to self-learning, and accessible to all IBP stakeholders.

- Such decisions will be executed automatically where possible, as all con[1]textual information available will be stored.

- Human adjustments made to the system-generated recommendations will benefit from feedback, reducing the impact of human biases.

For a company to transform from a traditional planning process to one segmented by human and machine decision making can be quite a journey. Changes will be required to operating models and systems, roles and organizational structure, rewards, and incentives. Additionally, planner capabilities will need to adjust to collaboration with the machine. Still, it can be done.

During COVID, the global CPG giant Unilever compressed its planning cycles from four weeks to one week, then to three days. It now combines human and machine aspects in its organizational structure with machine reporting to a human. It has clearly defined when the human is in the loop, on the loop, or out of the loop in decision making. Unilever’s approach may pave the path to the new norm for IBP.

Conclusion

The traditional IBP process and supporting Waves 1 and 2 planning technologies are a generation old and incapable of effectively adapting to today’s challenges or taking advantage of innovations in technology. Long overdue is a reset of traditional processes to approach IBP from a decision perspective. Supported with today’s systems of intelligence, we can assess where the machine should automate decisions and where the human will guide the machine and lead in decision making. We can then integrate IBP into day-to-day business meetings, rather than maintain it as a separate planning process.

Neils, always good thoughts form you on such an important topic ! I think the challenge of synchronizing basic supply chain execution data between entities / enterprises / nodes must be addressed first before even simple S&OP plans can be effectively and reliably deployed. Decentralized network, secured, distributed data systems is a key answer to this long standing need as nearly all current ERP and supply chain data only collects and stores deep water wells of independent data with no capability and worse yet INTEREST in connecting. The interesting phenomenon we have experienced with clients ( helping big and small companies with S&OP / synchronize their supply chains) is once the data is reliably and when in place so many great decisions can be made quite simply with the human mind and instincts.

We believe greatly in power of human instinct, decision making and statistics and that machines are not decades but hundreds of years behind even a solid human trained in basic finance and production planning concepts.

Here is a very basic concept of a 2×2 matrix explaining collaboration. A concept have been using for 30 years but recently reintroduced by Gartner. It is the different place different time intersection that is so badly need in supply chain tech. We have suffered through 15 years of IT distraction that “cloud” automatically address this need and it does not at all. It is the decentralized network, secured, decentralized distributed database capability that enables this business to business collaboration and then breaking S&OP free to the masses !

https://soptime.wordpress.com/2021/09/02/collaboration-framework-for-supply-chain-synchronization/

Keep up all the great work ! Maybe we can work together on a few projects soon !