Trends That Will Transform Manufacturing in 2023 & Beyond

RFgen

FEBRUARY 10, 2023

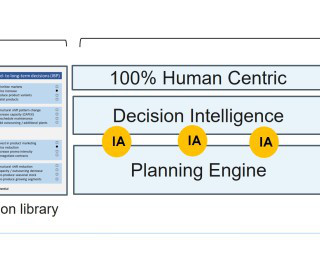

Supply chain optimization and attracting talent will continue to be top-of-mind for manufacturers. Artificial intelligence (AI) is most likely to transform the manufacturing sector. Manufacturing has changed dramatically in recent years. In fact, over half of U.S. Integration remains a challenge, however.

Let's personalize your content