Top 5 Logistics Challenges and Solutions for the Manufacturing Industry

GlobalTranz

MARCH 17, 2022

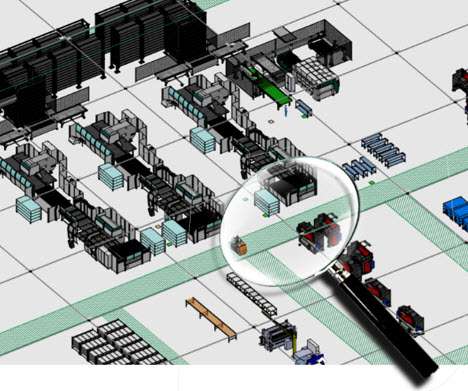

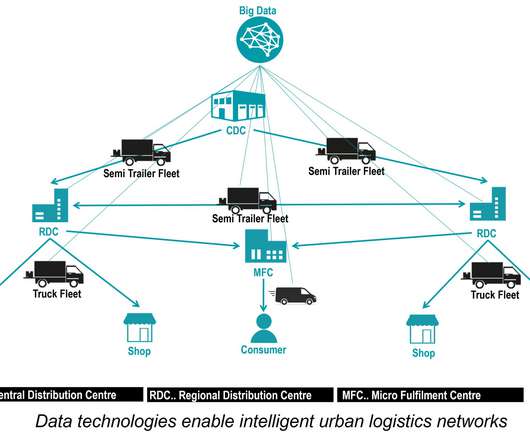

The manufacturing industry faces many challenges, such as a skilled labor shortage, supply chain instability, and inventory management issues. GlobalTranz works with manufacturing shippers every day to move their goods and streamline their logistics strategies. 5 Challenges Facing Supply Chain Managers in Manufacturing.

Let's personalize your content