Exploring the Many Applications of AIMMS in Supply Chain Planning

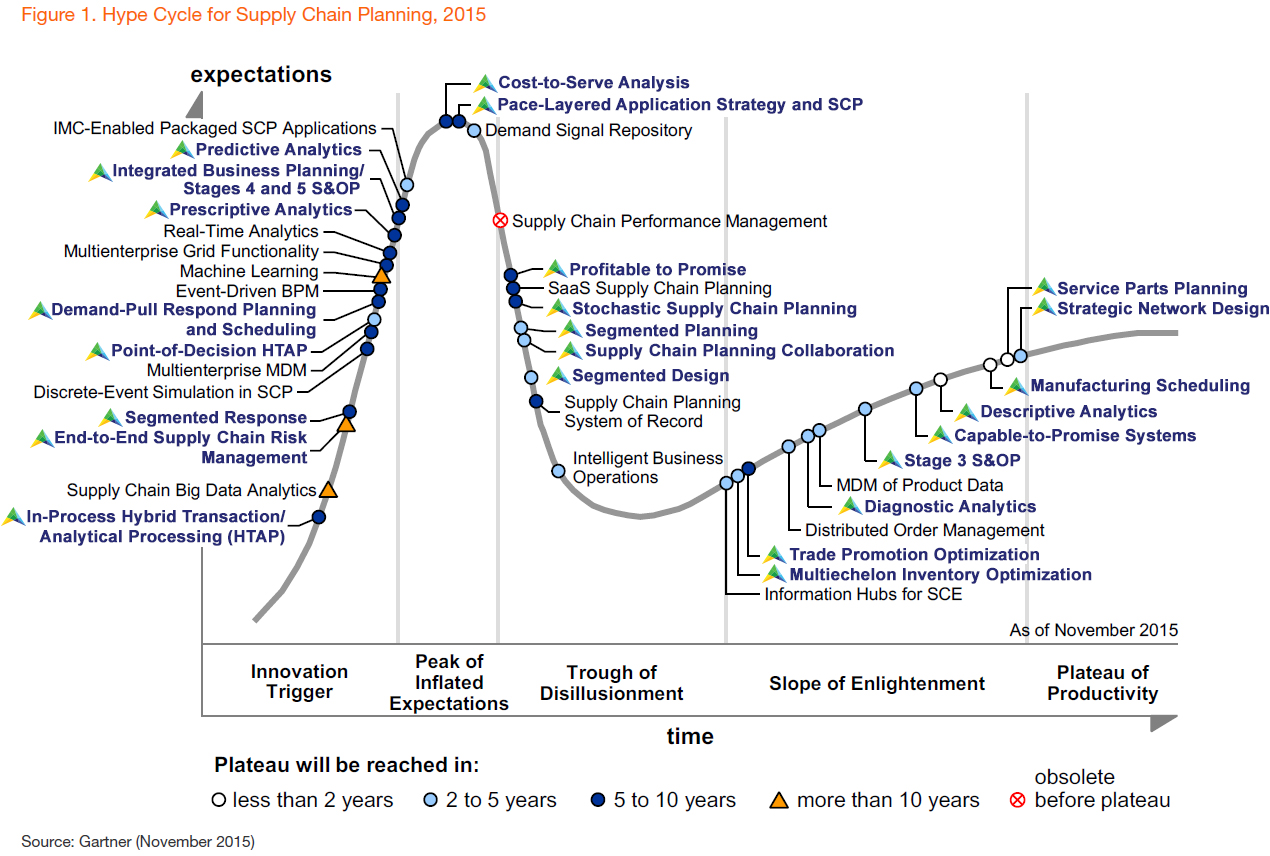

As you may have heard, AIMMS was recently featured in Gartner’s Hype Cycle for Supply Chain Planning (SCP). The Hype Cycle is a great resource for Supply Chain and IT leaders. It offers an overview of the enormous breadth of solutions for Supply Chain planning, giving you insight into the many fields where you can leverage technology to boost your company’s performance. It also helps you understand which technologies and applications have gone through their teething cycle, which ones are already mature, and ultimately, which one would be right for you. In the document, Gartner positions AIMMS as a key vendor in Prescriptive Analytics – a form of Advanced Analytics that can improve decision making in several areas of the supply chain, including logistics, planning, and manufacturing. But you can apply AIMMS to many other areas as well. I will explore some of those areas in this post.

Applying AIMMS throughout the Hype Cycle

Gartner’s Hype Cycle for SCP covers a spectrum of planning capabilities and applications – from those on the rise to those climbing the slope. Being a flexible optimization platform, AIMMS is poised to help companies navigate and embrace these different capabilities to stay ahead of the curve. Our software enables you to build tailor-made apps to achieve more than half of the capabilities described in the Hype Cycle, including:

- In-Process Hybrid Transaction/ Analytical Processing (HTAP)

- End-to-End Supply Chain Risk Management

- Segmented Response

- Point-of-Decision HTAP

- Demand-Pull Respond Planning and Scheduling

- Prescriptive Analytics

- Integrated Business Planning/Stages 4 and 5 S&OP

- Predictive Analytics

- Cost-to-Serve Analysis

- Pace-Layered Application Strategy and SCP

- Profitable to Promise

- Stochastic Supply Chain Planning

- Segmented Planning

- Supply Chain Planning Collaboration

- Segmented Design

- Multi-Echelon Inventory Optimization

- Trade Promotion Optimization

- Diagnostic Analytics

- Stage 3 S&OP

- Capable-to-Promise Systems

- Descriptive Analytics

- Manufacturing Scheduling

- Strategic Network Design

- Service Parts Planning

As the list shows, AIMMS can be leveraged to support complex planning and decision making at multiple Hype Cycle stages. Let’s look at some use cases in more detail.

JBS: tailor-made apps for IBP/S&OP, Capable-to-Promise and Profitable to Promise

Our customer JBS, for instance, has built applications for IBP/S&OP, Capable-to-Promise and Profitable to Promise. JBS is a global leader in meat processing. The system that they developed allows them to respond rapidly to changing market prices for all of their (intermediate) products on a daily basis. In addition, it allows them to compare these insights with the latest update of their demand scenarios, production capabilities, transport possibilities, and all associated costs. As a result, they gained:

- A 25% increase to original margin

- 90% improvement on ‘adherence to plan’

- Increased adaptability and agility in the planning process

- An optimized product portfolio with the right inventory levels

- The ability to integrate Cost-to-Serve analysis and considerations into the S&OP process

- The ability to collaboratively explore multiple scenarios

Nampak: driving profitability with Demand-Pull Respond Planning and Scheduling

Nampak, Africa’s leading packaging company, traded Excel for an AIMMS-based planning and optimization tool. Their solution would be best described by Gartner as an application for Demand-Pull Respond Planning and Scheduling. Named GOBSS, Glass Optimization Business Software Solution, the tool leverages AIMMS technology to support the company’s schedulers, sales and management teams to make the best business decisions through the evaluation and optimization of profit scenarios.

Thanks to GOBSS, Nampak is able to:

- Respond quickly to customer changes in the market and production changes internally

- Quantify planning changes in a financial way

- Extract more value from their planning process

- Maintain customer service at a reasonable level of profit for the business

A top U.S. food manufacturer experiments with Strategic Network Design

Another customer, this time in the food manufacturing space, has used AIMMS to build a Strategic Network Design application. With highly perishable products and a large number of SKUs driving complexity, this growing U.S. food manufacturer was determined to asses if their existing operations were as efficient as they could be. AIMMS was selected as the Modeling Technology for a network assessment. The AIMMS model was created in only two weeks and helped the team address key questions pertaining to logistics and overall fulfilment costs. Conducting What-If Analysis and reviewing over 20 different scenarios helped the team identify options for cost reductions that ranged from 10-25%, which amounts to millions of dollars annually. The cost savings helped the company further invest in R&D and subsequently launch several new product lines.

A leading retailer leverages AIMMS for Point-of-Decision HTAP

A large retail chain was experiencing the effects of increasing competition, changing consumer habits and tastes and pricing/margin pressure. In addition, each of their category managers was evaluating suppliers and conducting sales planning independently. Everyone had their own spreadsheet and tracking process. The company decided to seize the opportunity to conduct planning and cost management holistically and provide enhanced analytic support for decision-making to all category managers. An integrated optimization platform was created with AIMMS technology and is now used across dozens of categories to help the merchandising team identify the optimal scenarios in a dynamic environment. Thanks to this platform, the retailer’s team now has more visibility into costs, customer trends and has enhanced insights to make better decisions about pricing, promotions and assortment.

The list of applications goes on, the only question remaining is – where should you start? It may seem like a daunting question, but it’s actually quite easy to answer. Start with your most critical business problem, ask yourself what you’re trying to achieve and find a planning or decision support solution that fits like a glove.

Leveraging AIMMS throughout the Hype Cycle

Gartner positions AIMMS as a leader in Prescriptive Analytics. And useful as that is on it’s own right, it masks the true value of an Enterprise Modeling & Optimization Platform. As the array of examples demonstrate, you can apply AIMMS as your innovation technology throughout most of the Hype Cycle stages. AIMMS’s flexible modeling platform can be used to develop tailor-made apps to optimize almost every area of the supply chain. What this looks like, and how this works for other companies, is explained in another Gartner document “Use cases for an Enterprise Supply Chain Modeling Platform.”