The aeronautics supply chain is in the midst of a rebound after the pandemic. This ramp-up has been accompanied by multiple challenges: recruiting lost skills, synchronizing a large network of suppliers, dealing with capacity challenges, and managing the multiple risks linked to geopolitical tensions.

More than ever, it is essential to maintain end-to-end visibility on flows — and work to accelerate and protect them. Nothing would be worse in this context if each of the actors of the supply chain did not work on the right priorities.

A few players in this sector have adopted Demand Driven tactics, which has helped them in this turbulent period, but they are still in the minority. The sector is still mainly driven by a traditional MRP model, with some Lean practices at some industrial sites, but few large-scale pull flows.

What are the challenges of the aviation value chain, and how are Demand Driven tactics appropriate?

The Illusion of Demand Stability

Aircraft manufacturers’ order books are full for the long term. Orders for both Airbus A320s and Boeing 737s represent years of portfolio. Last May, Airbus announced a 25% increase in production rates to 75 A320s per month by 2025.

With such visibility, one might think that this industry is immune to demand variability.

And yet, any aeronautical equipment manufacturer will tell you that there are major fluctuations. We’re not talking about the pandemic, which drastically reduced volumes and jeopardized several players in the chain — even in normal times, delivery requirements for the various components fluctuate, in terms of quantity or date. The further up the chain you go, the more obvious this is. While we can recognize the aircraft rate when we are a Tier 1 supplier, Tier 2 suppliers and above have a very blurred visibility, due to an omnipresent bullwhip effect.

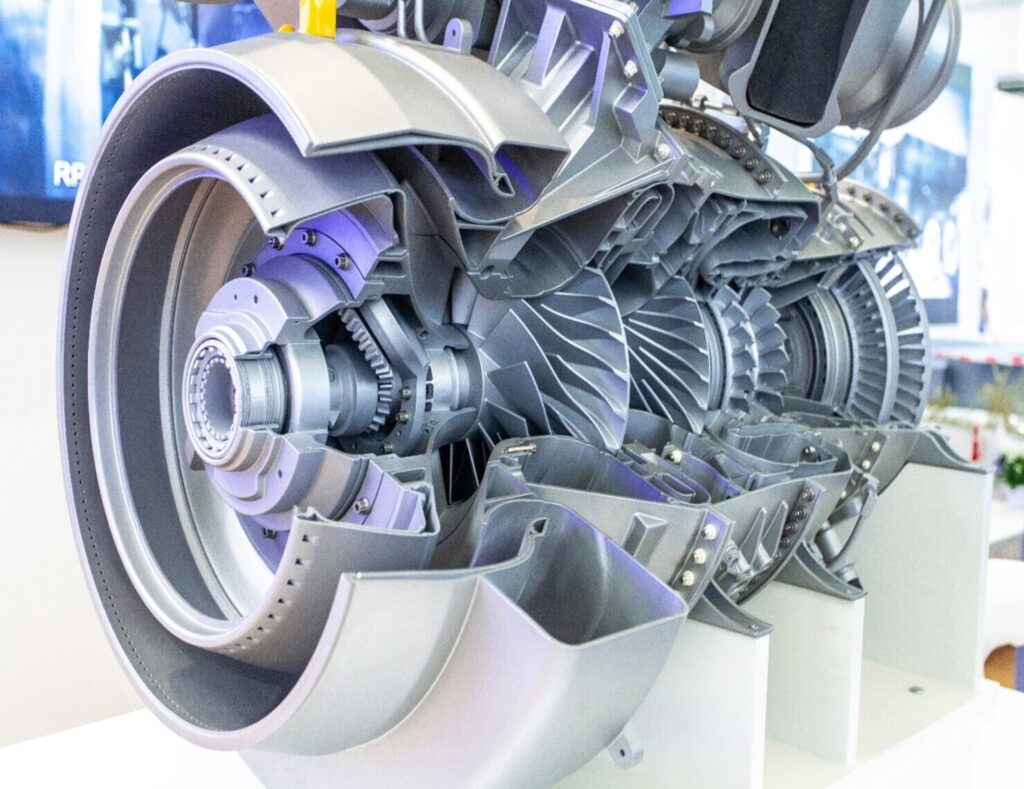

Part of this demand variability comes from the planning logic the industry uses, but also from the complexity and technical nature of its flows, which induce “collateral” variability. To manufacture an aircraft, tens of thousands of parts are needed, and therefore many players must be synchronized. Each delay, capacity problem, or quality problem of one of the players will have its own consequences on the other players in the chain.

In this industry, too, being able to respond agilely to real demand, and thus using appropriate pull methods, is a key success factor.

High Mix, Low Volume

I spent a large part of my career in the automotive industry, on the parts manufacturer side, where I put into practice the pull flow techniques that have become widely used in this sector, in the wake of Toyota. The first time I was exposed to the problems of an aero supplier, I understood that it was a very different context, and that, even if the principles of real demand-driven flow remain valid, the automotive techniques cannot be duplicated as they are.

To take an image, in the automotive industry you have 30 references to manufacture, for an average quantity per reference of 2000 per day, whereas in the aeronautics industry you have 2000 references to manufacture, for an average volume of 30… per month, if not per year.

You simply cannot use traditional Kanban techniques, especially physical Kanban, to pull the flow. However, DDMRP buffers provide a digital solution that is easy to implement and maintain over time, and that immediately provides clear visibility on the right priorities.

An Industry of Engineers

A second characteristic of this sector is that it is very high-tech, and therefore requires a panel of very specialized suppliers who are able to provide the required technical know-how, often with very narrow process windows.

The industry has a network of leading-edge SMEs, selected more for their technical capabilities than for their excellence in flow management or their location. During a recent conference, Philippe Gaulier, the Safran Group’s Supply Chain Director, testified to the fact that during its manufacturing process, a landing gear can travel the equivalent of several times around the world.

The aeronautical supply chain was not primarily designed to enable a fast and reliable flow of goods. It was designed to deliver the required product, meeting technical, quality, and safety specifications — something we look forward to every time we get on a plane.

For supply chain managers in the sector, this means that flows must be accelerated and made more reliable while having limited influence on their design. The focus will therefore be on the design of the control model: Visibility of priorities, positioning of decoupling points, positioning and control of queues, and scheduling and optimized use of capacity constraints. Demand Driven techniques, and specifically the DDOM model, provide concrete solutions for this, which can be implemented in a short period of time.

Complex Operating Ranges

A corollary of the high mix/low volume context and the technical nature of the manufacturing steps is that, in general, it is not possible to put the manufacturing processes inline, as would be done in the automotive industry.

The predominant manufacturing model for aerospace equipment manufacturers is the job shop. One uses specialized production cells (machining, fitting, welding, surface treatment, coating, molding, baking, subcontracting, control, etc.). Each equipment is shared by several flows. The routings can include dozens of operations and can take several weeks to complete. In this context, priority conflicts are frequent, and the queues, whether controlled or not, constitute a major part of the lead time and capital tied up in this chain.

Managing this complexity often requires teams of flow managers / business managers / part hunters, and a lot of attention and energy to protect customer deliveries.

The Demand Driven model and Intuiflow bring several elements to simplify this complexity and accelerate the flow:

- The implementation of intermediate decoupling points where appropriate

- The implementation of “Drum-Buffer-Rope” techniques from the Theory of Constraints control the following:

- The flow by some key points, in particular by the bottlenecks

- Control/reduction of the work-in-progress, to speed up crossing times and limit priority conflicts

- Time buffer management, to move from uncontrolled jammed queues to chosen and managed queues, with unambiguous visibility on priorities

Follow the Pioneers

Even if Demand Driven practices are still emerging in the aeronautical industry, some pioneers have shown the way and demonstrated the efficiency of the techniques involved. Our customers Figeac Aero, Hutchinson, Royal Engineered Composites are among them. Do not hesitate to contact us to evaluate how Intuiflow can help you in the management of your aeronautical flows!