Baltimore Bridge Collapse: An Opportunity to Reinforce the Importance of Supply Chain Resilience

Logistics Viewpoints

APRIL 10, 2024

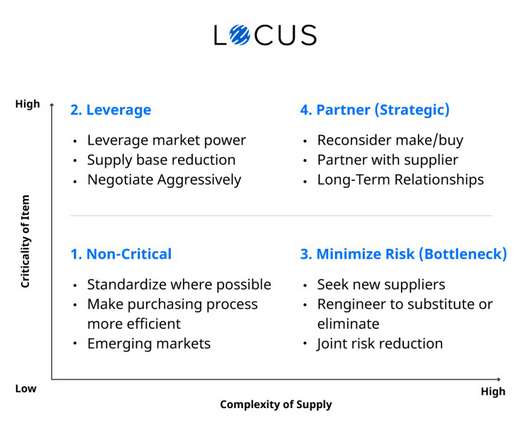

Supply chain resilience is a hot topic the last few years since post-Covid issues and newsworthy incidents like the Houthi attacks in the red sea have raised awareness. The bridge collapse is a stark reminder of the vulnerability of the nation’s aging infrastructure and the importance of supply chain resilience.

Let's personalize your content