Multi-echelon Inventory Optimization vs Inventory Optimization

ToolsGroup

MARCH 24, 2021

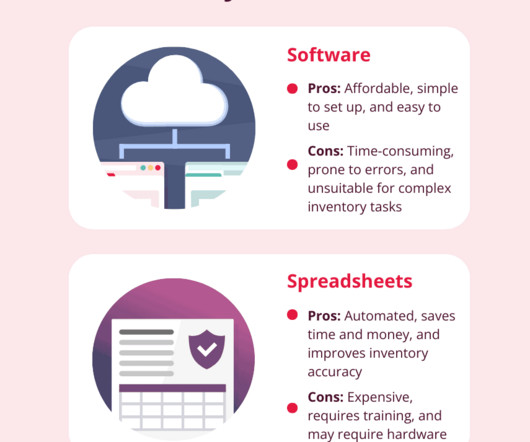

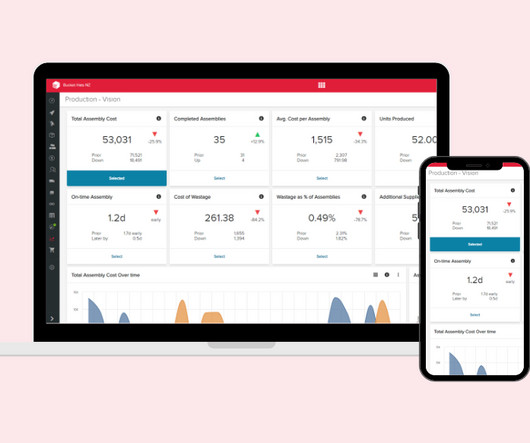

Now consider that by not optimizing your inventory from a global vantage point you may be creating, if not outright chaos, a much less efficient network than you could have. There are many pieces of the modern manufacturing supply chain. The basic approach to inventory optimization. This is no easy task.

Let's personalize your content