What is the Warehouse Role in Fulfilment?

Supply Chain Game Changer

OCTOBER 5, 2022

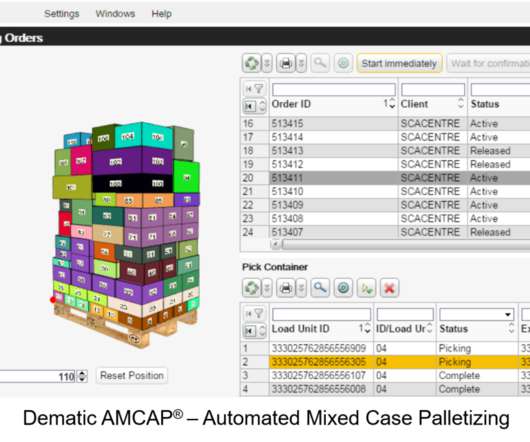

Featuring Our 10 Best Warehouse Order Fulfillment Articles! There is nothing new about warehousing. Whilst a modern warehouse clearly does a lot more than stockpiling food, the principle remains, including the warehouse role in fulfilment. Warehousing – the basics. Warehousing – the basics.

Let's personalize your content