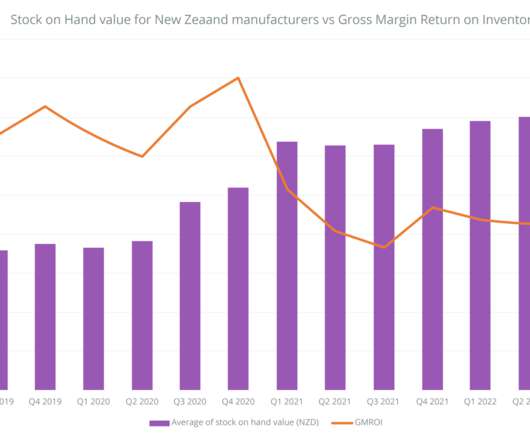

The Manufacturers Health Check: Firms Holding Double the Stock Amidst ‘Inventory Crisis’

Unleashed

NOVEMBER 16, 2022

The Manufacturers Health Check report shows SMEs in the UK, New Zealand and Australia were forced to hold record levels of stock in Q3 2022 – a response to billowing international lead times. However GMROI fell from 1.5 Fulfilment times dropped too by just under a day and a half, from 12.1 days on average.

Let's personalize your content