6 Game Winning Strategies for Continuous Improvement

USC Consulting Group

AUGUST 4, 2020

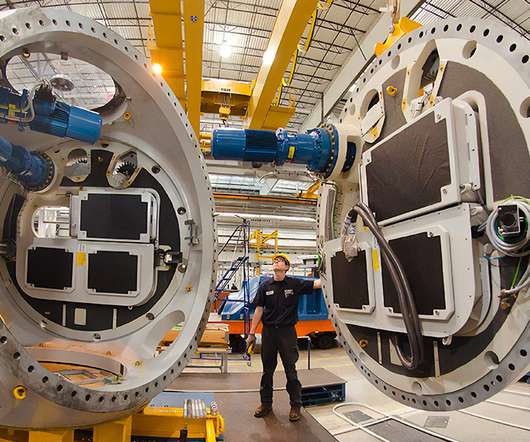

Continuous improvement strategy. The winningest teams are always looking to continuously improve by mastering the fundamentals and putting in the time and dedication to perform when the clock is ticking down and the next score wins. Continuous improvement isn’t a destination; it’s a mentality.

Let's personalize your content