What Industry Leaders Have to Say About Virtual Twins in Manufacturing

DELMIA Quintiq

FEBRUARY 14, 2022

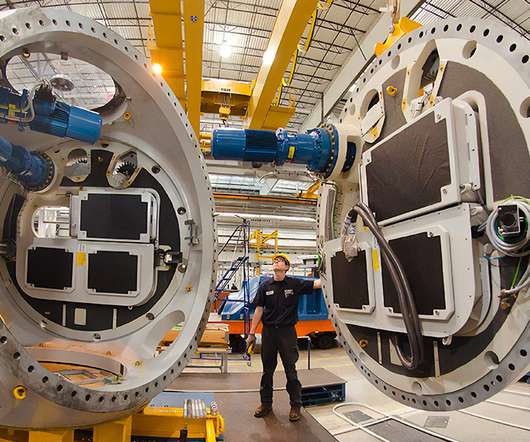

The past year and a half saw manufacturers face unprecedented challenges resulting from global disruptions, to which they responded by repurposing or developing new product lines, reconfiguring their plants and restructuring their supply chains in order to meet changing demands and keep afloat amidst uncertainty.

Let's personalize your content