Multi-echelon Inventory Optimization vs Inventory Optimization

ToolsGroup

MARCH 24, 2021

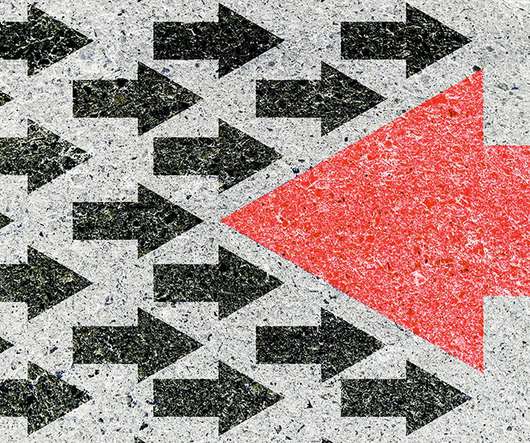

Now consider that by not optimizing your inventory from a global vantage point you may be creating, if not outright chaos, a much less efficient network than you could have. When it comes to inventory management, each piece must operate as a part of a global integrated system to be most effective.

Let's personalize your content