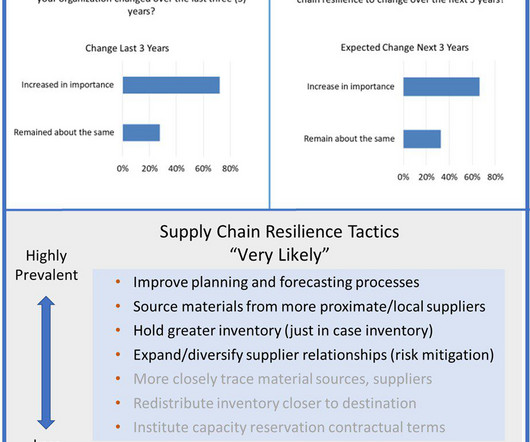

Build Supply Chain Resilience with a Diverse Sourcing Strategy

Logility

APRIL 20, 2022

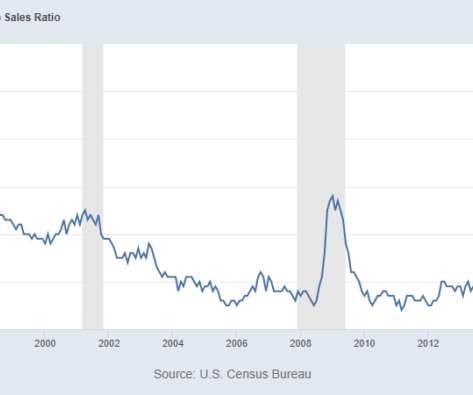

With access to digital data across your enterprise ecosystem and your multi-enterprise partners’ system, you can measure variability in demand, lead time, production capacity, throughput performance, resource availability, and transportation schedules with planning algorithms. Developing Diverse, Resilient Sourcing Strateg ies.

Let's personalize your content