What is Just in Time Manufacturing? Benefits & Disadvantages

Unleashed

APRIL 18, 2024

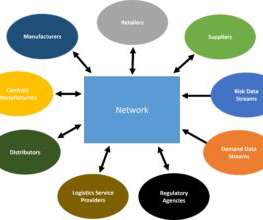

Just-in-time (JIT) manufacturing is a production management approach that helps you lift efficiency and streamline your operational processes. What is just-in-time manufacturing? The just-in-time approach contrasts with just-in-case strategies, where producers hold sufficient inventories to absorb maximum market demand.

Let's personalize your content