Supply Chain Fraud 101

Logistics Viewpoints

JULY 13, 2022

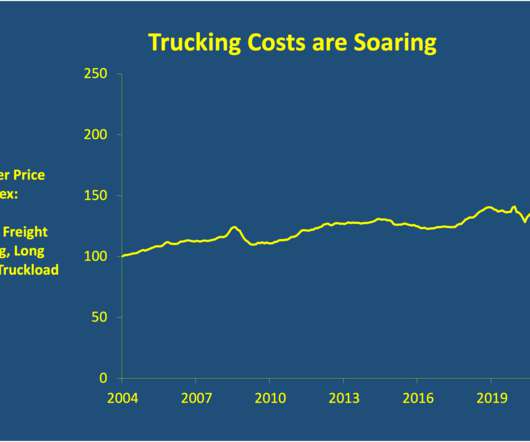

Weather delays can affect shipping lanes, manufacturers face product shortages, demand continues to spike for certain products, containers are difficult to acquire, and the trucking industry faces a driver and capacity shortage, just to name a few. When we think of fraud in the supply chains, often we think about organized cargo theft.

Let's personalize your content