Just-in-Time vs. Just-in-Case Procurement During Supply Chain Disruption

Ware2Go

JANUARY 7, 2022

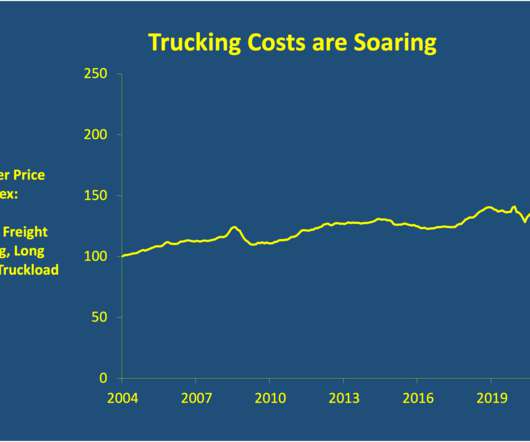

Recent supply chain disruptions , including images of cargo ships stuck off the West Coast , have led eCommerce shops to rethink their just-in-time and just-in-case inventory strategies. . About 9% even had stopped offering free shipping to recover costs, while 7% held off on ordering peak inventory to see if prices would level off.

Let's personalize your content