Reverse Logistics Companies: Using Metrics to Track Performance

GlobalTranz

JULY 28, 2020

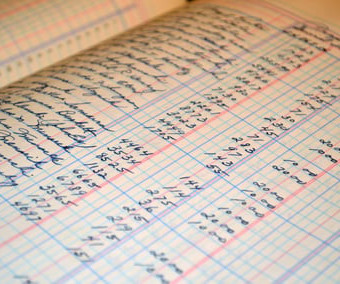

The post Reverse Logistics Companies: Using Metrics to Track Performance appeared first on Transportation Management Company | Cerasis. According to Jeff Ladner via Supply & Demand Chain Executive, the maintenance, repair, and operations materials costs comprise up to 15% of total operating costs.

Let's personalize your content