Best AI Tools for Supply Chain and Logistics: The Ultimate Guide for 2024

Exploring the world of AI tools for supply chain and logistics can be quite overwhelming. There are so many options out there that it is hard to know where to start and what to choose.

We get it!

That’s why we put together this guide – to help you get a glimpse of the best AI tools for supply chain and logistics, how to implement these tools, what to take care of and more.

Best AI Tools for Supply Chain and Logistics

1. ThroughPut AI: For Making Intelligent Decisions Across the Supply Chain

Watch On-demand Demo

ThroughPut AI has been recognized as a Leading Vendor in the prestigious 2023 Gartner Market Guide for Analytics and Decision Intelligence Platforms in Supply Chain.

ThroughPut’s AI-powered tool equips decision-makers throughout the supply chain with actionable recommendations, enhancing the quality and effectiveness of decisions at every level.

The platform offers real-time visibility into demand and market fluctuations, enabling users to respond with agility and maintain resilience under changing market conditions.

At the operational and tactical level, it supports daily activities through effective demand sensing, SKU optimization, logistics planning, replenishment planning, capacity management, and more.

Strategically, it provides Chief Supply Chain Officers (CSCOs) with insights into how each decision affects the company’s finances.

Main Features

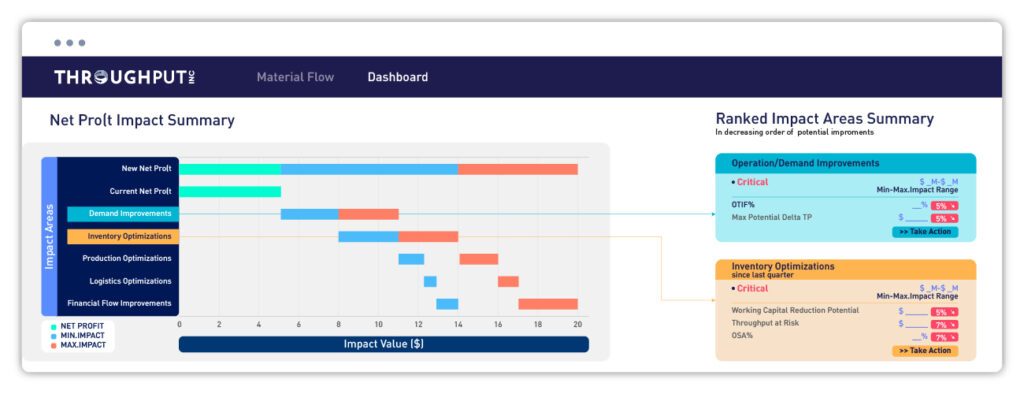

- Advanced cognitive analytics powered by AI and machine learning

- Customizable dashboards and visual representations that are easy for anyone to understand

- Real-time decision-making enabled by a unified data hub that offers complete visibility from upstream to downstream operations

- A comprehensive net profit overview to help businesses understand the financial outcomes of optimized supply chain operations

Main Benefits

- Scalable and adaptable to various business needs

- Improvements in on-time in-full (OTIF) delivery and free cash flow

- Faster integrability and implementation

- Ability to pinpoint areas with the highest and quickest potential for improvement

- Key metrics such as Demand Sensing, Constraints Management, Capacity Planning & Management, and Financial & Logistics Planning are driven with accuracy

2. Logility: Supply Chain Planning & Optimization

Logility assists global businesses with complex supply chains in sensing and responding to fluctuating market conditions. The platform is designed to enhance inventory management and provide accurate demand planning and forecasting, crucial for optimizing supply chain efficiency.

Main Features

- Advanced analytics driven by AI

- Inventory optimization

- Demand forecasting

- Integrated business planning

- Alerts for stockouts, replenishment cycles, and minimum inventory

Main Benefits

- Enhanced response times

- Automated strategies like collaborative planning, vendor-managed inventory, forecasting and replenishment, and more

- Inventory optimization with a reduction in obsolete inventory and effective fresh item management

3. Blue Yonder: Comprehensive Supply Chain Planning Solutions

Blue Yonder is an omnichannel planning platform that enables order fulfillment. The platform primarily helps predict demand and improve customer experience.

Main Features

- AI-based predictive analytics and demand forecasting

- Visibility from procurement to delivery

- Aids with stock-level optimization

Main Benefits

- Effective anticipation of market changes and risk management

- Enhanced inventory management

- Accurate forecasting for business goal alignment

- A collaborative ecosystem for seamless communication between all stakeholders

- Improved customer satisfaction and loyalty

4. Oracle AI-powered Supply Chain Management: End-to-end Supply Chain Visibility

Oracle’s suite of AI-driven tools offers real-time visibility into the supply chain and promotes optimization of tasks across the supply chain. Hence, businesses can react to market changes, streamline their operations, and make well-informed decisions.

Main Features

- Tracking inventory, shipments and production status in real-time

- Using AI algorithms, Oracle’s suite helps understand supply chain risks and market fluctuations

- Demand forecasting

- Inventory management optimization

- Dynamic supply chain planning

Main Benefits

- Helps streamline operations, reducing time and costs

- Improved business decisions and customer satisfaction

5. Kinaxis RapidResponse: Real-time Supply Chain Planning and Response Management

Kinaxis RapidResponse is another AI-powered platform that helps in optimizing supply chain planning and response management. The tool empowers the business with agility to respond to disruptive factors, driving operational continuity.

Main Features

- Multiple scenarios can be tested in real-time

- Automated alerts of potential disruptions

- Risk management of supply chains

Main Benefits

- Enhanced agility to adapt to disruptions

- Optimize operations and reduce waste

- Mitigates potential risks

6. IBM Watson Supply Chain: Actionable Recommendations for Supply Chain Optimization

This supply chain AI tool from IBM leverages AI to transform supply chains with predictive and practical insights. It helps address disruptions and promotes innovation. The tools use cognitive technology to streamline operations across the global supply chain, driving efficiency, sustainability, resilience, and competitive advantage.

Main Features

- Predictive insights

- Real-time visibility

- Cognitive automation

- Customizable dashboards

Main Benefits

- Real-time visibility with proactive decision-making

- Optimized operations and optimized inventory levels

- Effective delivery of better services

- Facilitates collaborative efforts amongst all stakeholders

Now that you’ve an idea of the top AI tools in the market for supply chain, here are a few more things for you to know.

The What and Why of AI Tools for Supply Chain

There is a reason why everyone is talking about AI tools and why people are driven to make impulsive purchases of AI-powered tools.

Supply chain AI tools are powered by futuristic and promising technologies like machine learning, natural language processing, and predictive analytics. Together these capabilities facilitate better demand forecasting and planning, inventory management, procurement, and logistics, and augments visibility across the supply chain – far better than any technology or human has managed to do till date.

How AI Adds Value to Supply Chain Tools?

Before AI entered the supply chain scene, the industry used quite a few tools to automate parts of the manually driven process. This led to some level of improved efficiencies across the supply chain. But with the added capabilities of artificial intelligence, these conventional tools are now helping streamline operations by transforming data into strategic insights at a speed and level of accuracy never known before. This, in turn, is helping build responsive, agile, customer-oriented and far more sustainable supply chains.

Here’s how supply chain AI tools are making a difference.

- AI-powered Demand Planning and Forecasting: This is one of the core areas in supply chain management where AI has shown significant impact. The vast datasets available to businesses are progressively being used for short-term and long-term demand forecasting. This is not only driving greater accuracy but also enabling businesses to respond to market disruptions faster.

- Warehouse Automation Systems: With the intervention of AI, manual errors in warehouse management have reduced. Order processing and fulfillment are getting almost flawlessly executed. The movement of goods, to and fro, is happening faster, and storage space is getting optimized with the aid of robotics and intelligent algorithms.

- Inventory Management: Artificial intelligence in inventory management has enabled inventory tracking in real-time. This has further facilitated predictive restocking, optimization of stock levels, and minimization of waste. All of this is possible with advanced data analysis.

- AI in transportation and logistics optimization: AI in transportation and logistics has also made life easier for logistics and transportation companies in supply chains. Thus, routes and fleets are being managed better. AI tools in the supply chain are pushing down fuel consumption and costs. Delivery times are getting optimized, increasing operational efficiency and customer satisfaction.

- AI-based supply chain planning tools: Intelligent tools, AI-powered are helping identify supply chain vulnerabilities and loopholes. With agile decision-making, supply chains are becoming resilient, and sustainable, and businesses have better capabilities to anticipate and react to market changes.

How to Implement AI Tools in Supply Chain?

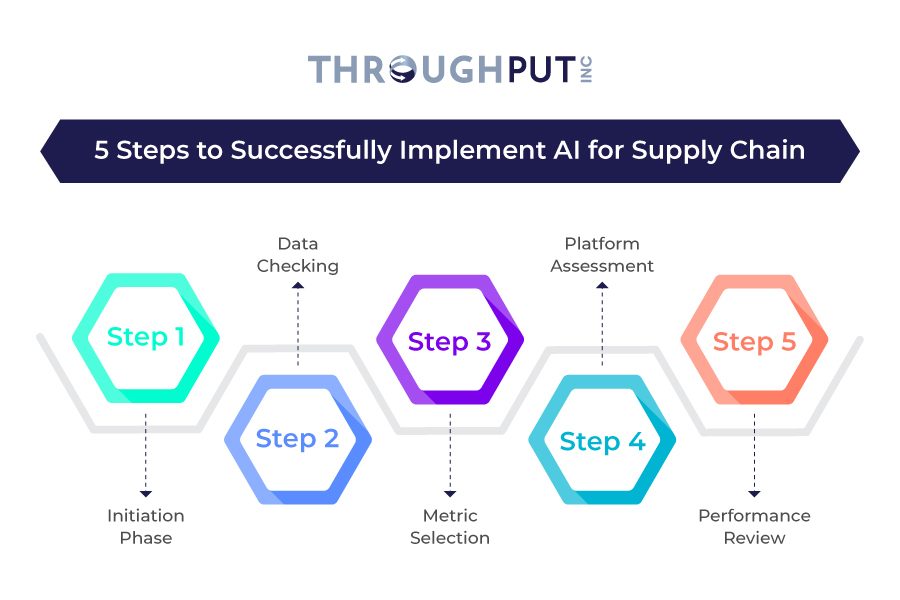

Implementing AI tools in supply chain broadly involves five steps:

Step 1 – Initiation Phase

This is where the current processes are mapped out and the problems are defined.

Step 2 – Data Checking phase

This phase involves focusing on data quality. This is where the data is prepared since the output will depend completely on the input data quality.

Step 3 – The Metric Selection phase

This phase involves identifying key metrics that will help track the actual impact of AI.

Step 4 – Platform Assessment

It is at this stage that you need to carry out a comprehensive analysis of the AI tool and compare the functionalities of the tool vis-a-vis the desired outcomes.

Step 5 – Outcome Review

In this final stage, the tool output is measured and assessed against the pre-defined objectives.

For more details, head over to our detailed blog on “How to implement AI in your supply chain?”

Overcoming Challenges and Barriers to Adoption of Supply Chain AI Tools

In most organizations, resistance to change is common – there are challenges of AI in supply chains.

Here are a few common barriers to adoption that must be addressed for smooth operations.

- Education and Training: Your workforce and other stakeholders must be comprehensively trained and familiarized with AI tools.

- Integration Support: Care should be taken that the new AI tool can be seamlessly integrated with existing systems to minimize disruption and smooth adoption of the technology.

- Addressing Data Security & Privacy: Another major challenge that should be addressed is regarding data concerns as it directly affects the reliability and integrity of the insights the tool provides. It is crucial that along with ensuring robust infrastructure, and compliance with data regulations, stringent data governance policies are implemented.

What are Examples of AI Implementation in Supply Chains?

The best examples of AI implementations in supply chains are Walmart, UPS and Amazon.

Here’s a breakdown of each example with additional background context:

- Walmart

Walmart uses AI tools extensively to manage its inventory and logistics. The tools help streamline operations and help Walmart anticipate customer preferences using the robust AI-powered demand forecasting systems.

The retail giant has been able to optimize stock levels and minimize stockout situations mainly due to the large-scale use of supply chain AI tools. In the long run, these tools helped the company save costs, and improve customer satisfaction.

- UPS

In the case of UPS, AI tools are an essential part of the supply chain, helping optimize transportation routes and reduce fuel consumption.

The tools have algorithms that analyze huge datasets to improve delivery efficiency by reducing delivery times and optimizing package routing. The tools have also helped UPS reduce its carbon emissions.

- Amazon

The e-commerce giant uses AI tools extensively taking its supply chain operations to another level. Consequently, reduced costs, optimized logistics, and improved customer satisfaction are a few metrics that the company has achieved with success.

From demand forecasting to route optimization, inventory management, and efficient order fulfillment, AI is being used by the company for end-to-end supply chain solutions.

Additionally, clients across industries like food, retail, military and defense, cement and transportation have benefited with Throughput’s new-age AI-powered platform in multiple ways.

For example:

- Church Brothers Farms uses ThroughPut AI to gain SKU-level granular visibility with up to 40% accurate and advanced forecasts for near-term demands and buying patterns, resulting in reduced wastage, minimized excess stock and optimized inventory space.

- Military and cement companies use Throughput to work with existing data to optimize various key supply chain metrics like demand sensing, capacity planning, logistics planning and demand segmentation for achieving faster ROIs.

- In the retail sector, clients have optimized product mix, logistics, and recorded phenomenal savings through smart pricing and promotion using Throughput.

Key Considerations for Selecting AI Supply Chain Tools

Consider the following factors when selecting supply chain AI tools.

- Functionality

Pick tools that have features aligned with your business goals and objectives. AI tools in the supply chain should be able to help you with accurate demand forecasting and optimize inventory, logistics, and route planning.

- Accuracy

This is the most important feature to consider when selecting the tool. Every insight offered by the tool should be accurate because all decisions will be based on these predictions. Compare the accuracy percentage of each shortlisted tool to choose the right one.

- Cost-effectiveness

The investment in the tool/s should be a smart decision. Your investment should be fruitful and the results aligned with the business objectives. In other words, the cost of implementation, running, and maintenance and the ROI should be viable.

- Integration

One of the must-consider factors in selecting the right supply chain AI tool is the integrability of the tool with the existing systems in use. This will ensure continuity of work without much disruption, ensuring compatibility end-to-end.

- Scalability & Customization Option

The tool should be able to support your future needs as the business grows. This means that the tool can be operated flexibly allowing businesses to start with a few basic models and then scale up, as and when required.

Choose the Right AI Tool for Your Supply Chain

Embracing AI is helping supply chains optimize operations, and making them agile. This way they are meeting customer demands more effectively, helping supply chains attain excellence in the digital age.

As supply chain intelligence evolves further, artificial intelligence and machine learning will continue to revolutionize supply chains and empower them with real-time insights and accurate predictive analytics. This will enable robust decision-making across the chain for all stakeholders.

Looking for a supply chain AI tool to optimize production and distribution capacity?

Get in touch with ThroughPut, your one-stop solution that leverages the full potential of AI integrated with industry best practices.