Blue Yonder Shakes Up the Supply Chain Software Market

Logistics Viewpoints

APRIL 1, 2024

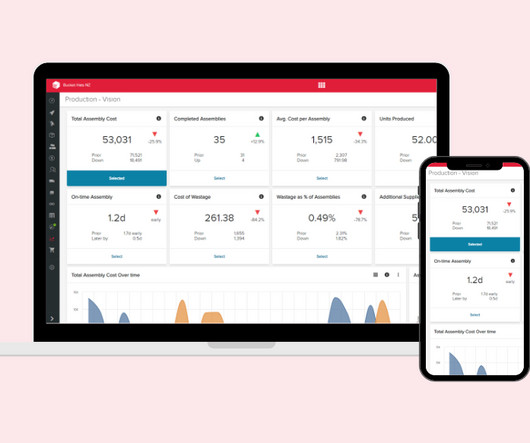

Blue Yonder’s CEO, Duncan Angove The supply chain software landscape is changing rapidly. This is a significant acquisition that will change the supply chain software landscape. This is a significant acquisition that will change the supply chain software landscape. Their SaaS revenues grew by 17% on a year-over-year basis.

Let's personalize your content