Demand Planning Software – Top 3 Demand Forecasting Mistakes to Avoid

Logility

JUNE 7, 2023

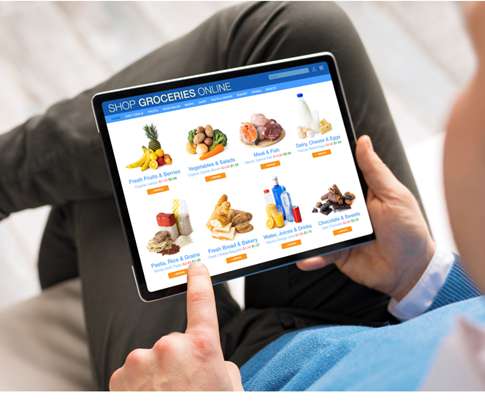

Top 3 Demand Forecasting Mistakes —How To Avoid Them with Demand planning software Demand forecasting is a critical facet of successful business operations, acting as the helm guiding companies through the rocks hiding beneath the water of market demands. What is Demand Forecasting?

Let's personalize your content