Demand Planning maturity levels and how to improve them

o9 Solutions

FEBRUARY 21, 2023

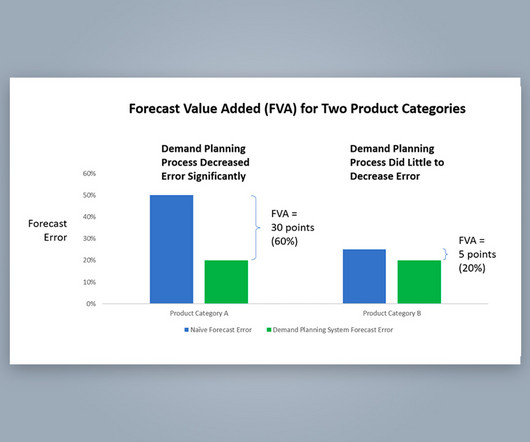

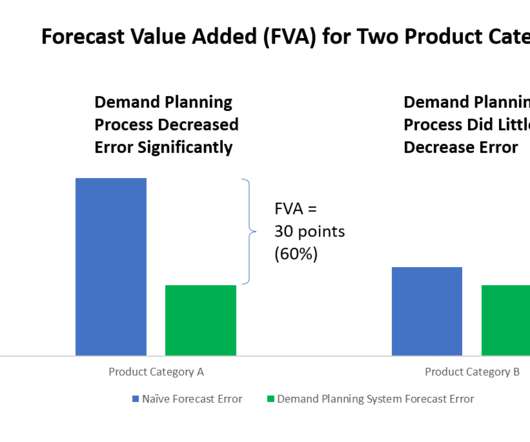

Which parts of your demand planning processes are most broken or need the most improvement? Understanding your planning maturity is the best pathway to resolving these system, data, process and resource challenges. A good demand planning process requires these elements to be defined correctly.

Let's personalize your content