Expanding Our Distribution Network — Strengthening Our Freight Services Through an Acquisition

Stord

NOVEMBER 30, 2022

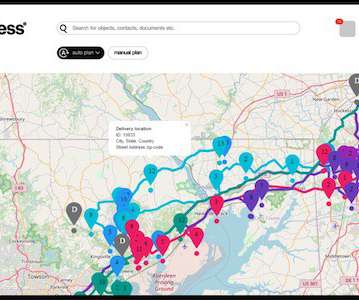

ATLANTA, June 12, 2020 -- Today, we are incredibly excited to announce that Stord has acquired Cove Logistics—a leading transportation provider—to further expand our distribution platform to include freight, strengthen our network of logistics capabilities, and better serve our customers.

Let's personalize your content