The Future of Supply Chains Post COVID-19 – LogiSYM July 2020

The Logistics & Supply Chain Management Society

JULY 22, 2020

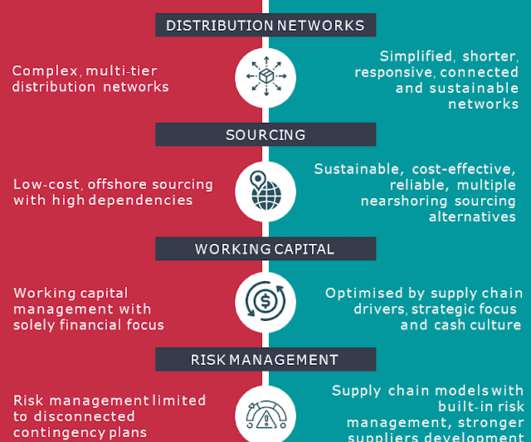

But companies will have to go beyond the usual inventory optimisation. . Such simulations would enable to assess the impact of a decrease/increase of demand, a capacity excursion in a factory or distribution centre. . Lastly, distribution networks will have to be shortened, products portfolio rationalised.

Let's personalize your content